Platform-based expandable rear torsion beam suspension structure

A torsion beam and platform technology, applied in the direction of suspension, elastic suspension, cantilever installed on the pivot, etc., can solve the problems of limited expansion capacity of torsion beam bearing capacity, waste of design and development verification, and heavy vehicle weight. Achieve the effects of reducing unsprung weight, facilitating processing, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

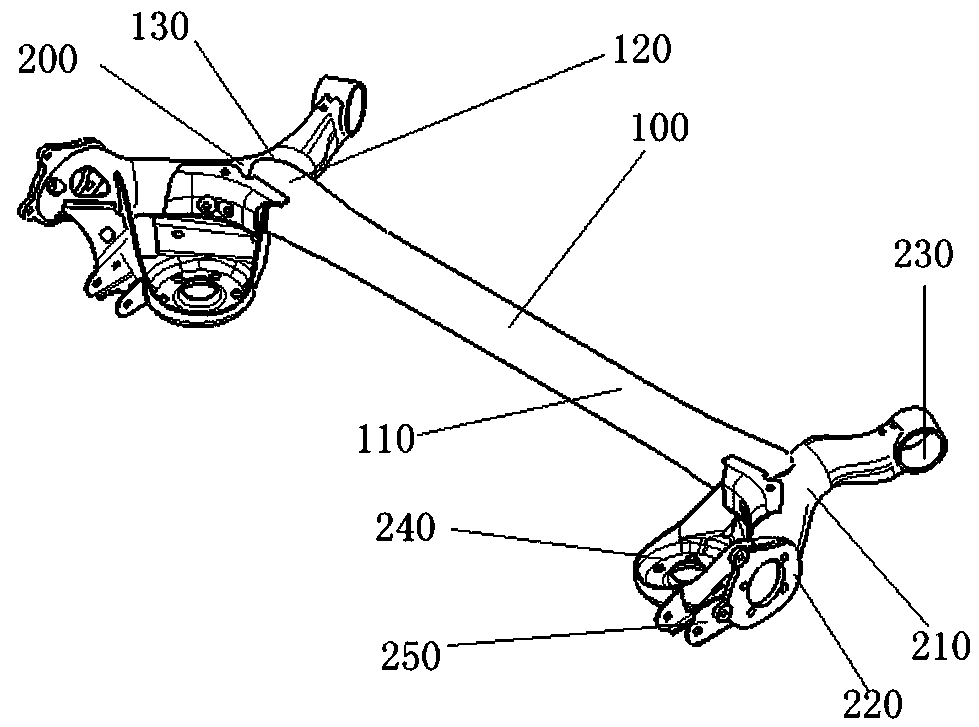

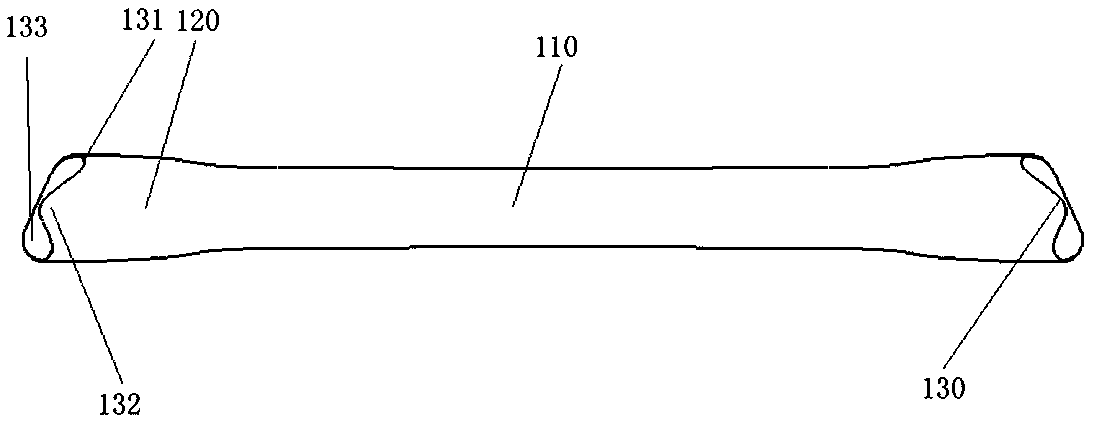

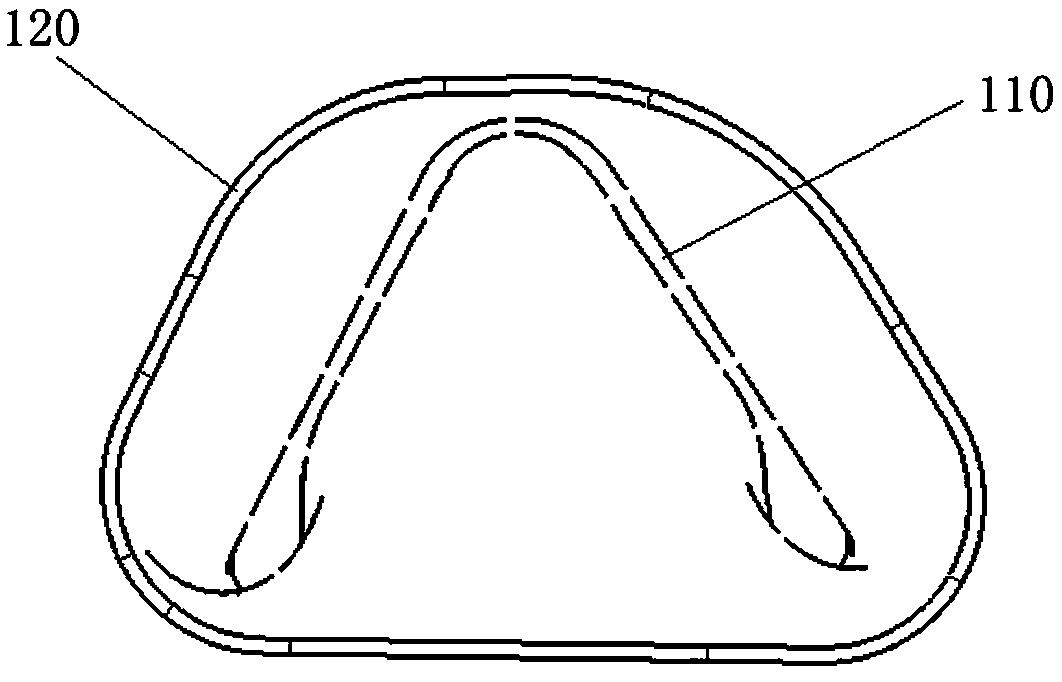

[0027] Such as figure 1 , 2 , 3, 4, and 5 show a platform-based expandable rear torsion beam suspension structure, including a crossbeam 100 and two trailing arm assemblies 200 symmetrically welded to both ends of the crossbeam 100, wherein the trailing arm assembly 200 mainly To bear the function of longitudinal force, the beam 100 mainly plays the role of bearing torsional force, resisting the roll and steering of the vehicle during driving. The crossbeam 100 includes a middle section 110 and an adjustment section 120 integrally connected to both sides of the middle section 110. The section of the adjustment section 120 is a closed trapezoidal shape with rounded corners. This shape can effectively support the weight of the upper vehicle body. Through the closed crossbeam 100, Under the premise of effectively reducing the weight of the rear suspension, it provides greater adjustment and load bandwidth to meet the needs of vehicle performance and load bearing. Its end is a c...

Embodiment 2

[0037] The technical scheme described in embodiment two is similar to embodiment one, and its difference is:

[0038] In this embodiment, in this embodiment, the cross section of the adjustment section 120 is a rounded triangle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com