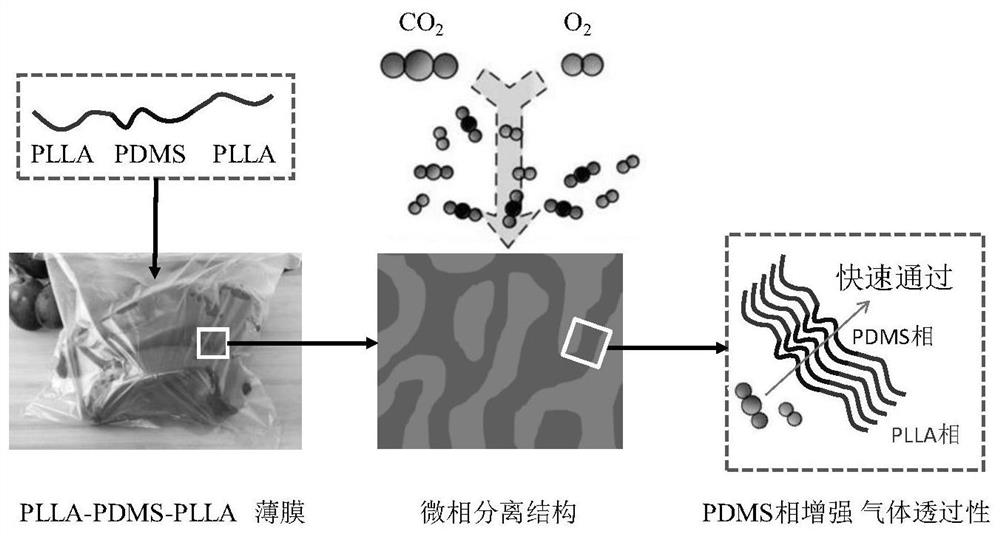

A high air permeability pld x l Copolymer film and preparation method thereof and application in preservation of fruits and vegetables

A fruit and vegetable preservation, PLLA-PDMS-PLLA technology, applied in the field of packaging materials, can solve problems such as spoilage and difficulty matching high respiration rate fruits and vegetables, and achieve high sensory scores, low microbial growth rate and weight loss rate, and tensile properties. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

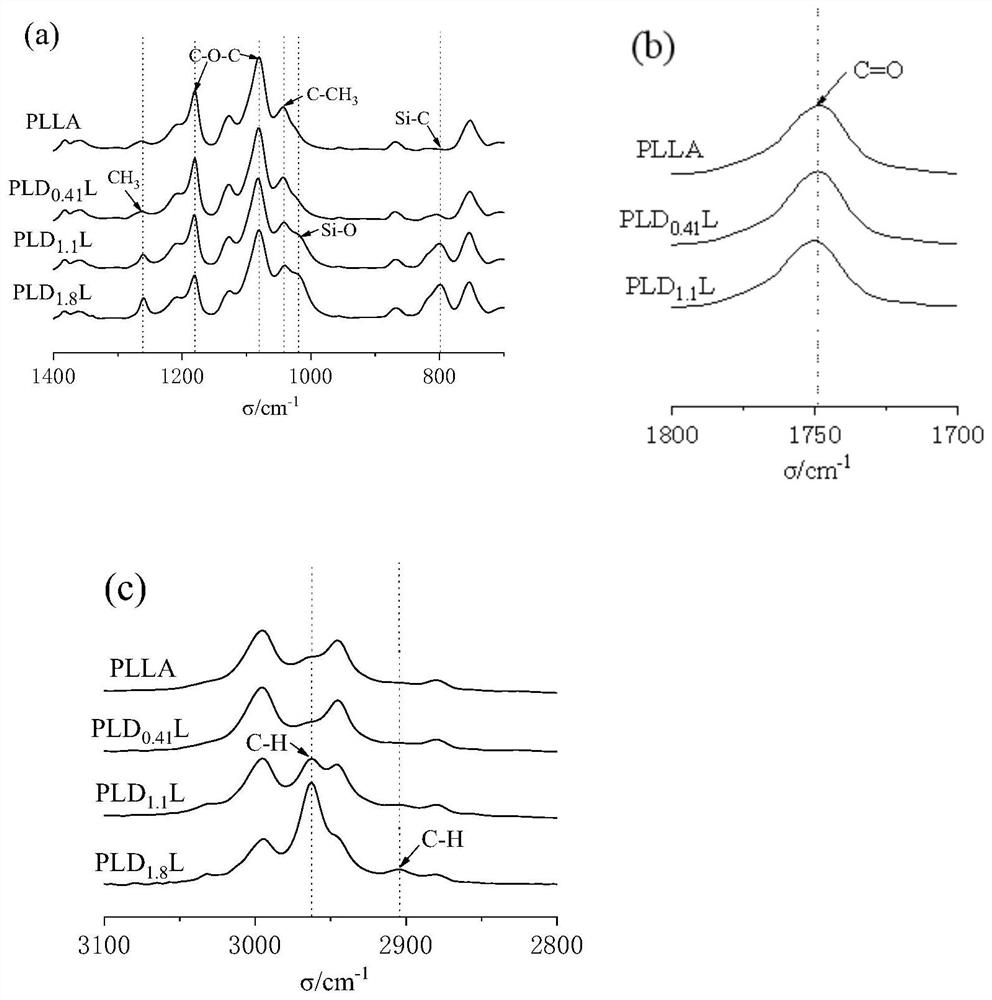

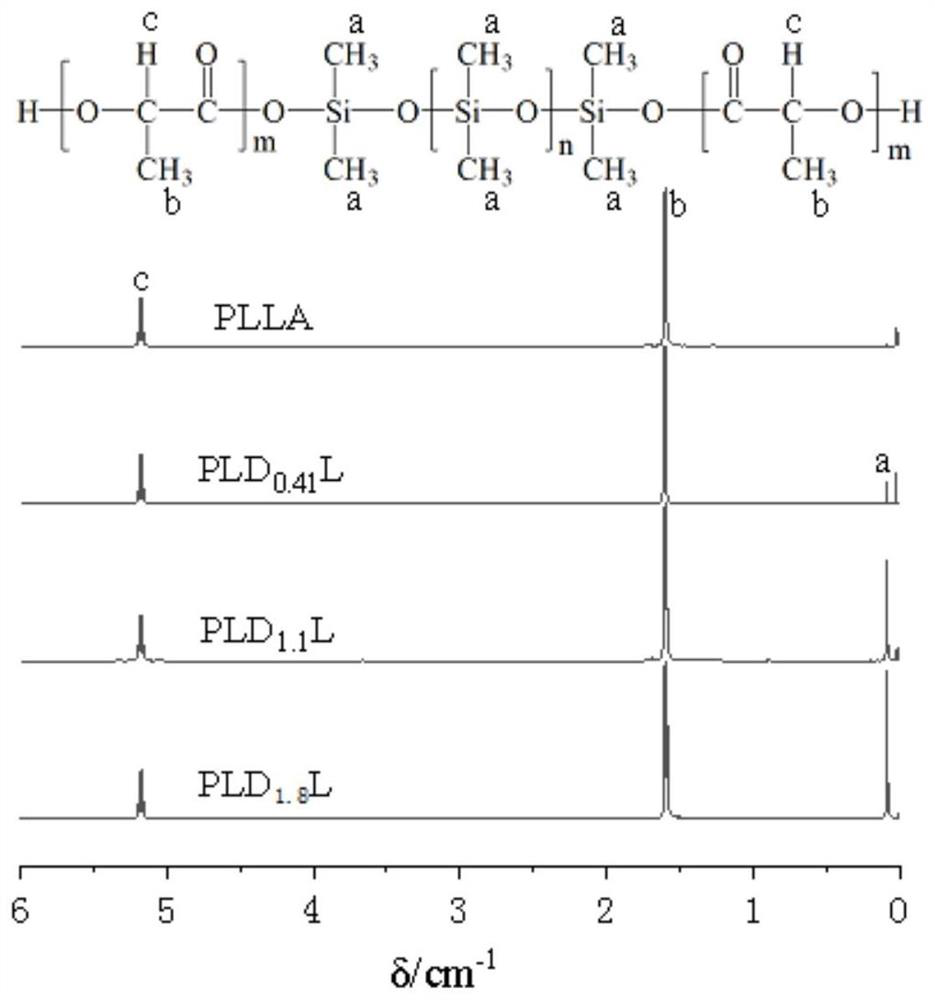

Embodiment 1

[0073] The highly gas-permeable PLD of the present embodiment 0.41 The preparation method of L copolymer film, described method specifically comprises the steps:

[0074] (1) First weigh 30 g of purified L-lactide and 1.8 g of PDMS (Mn: 4.1×10 3 , Mw: 4.2×10 3 ) (calculated by the molar ratio of the monomers) into a round-bottomed flask, and performed three gas replacements with inert argon. Pour 50mL of dried toluene into the reaction vessel, control the temperature of the oil bath to 130°C, stir while heating, and inject 0.15g of Sn(Oct) after the L-lactide and toluene are completely dissolved. 2 (5 / 1000 of the monomer mass), reacted for 48h. The reacted crude product was dissolved in 300 mL of chloroform, purified twice with 750 mL of n-hexane, and finally the white solid was vacuum-dried to constant weight, which was the PLLA-PDMS-PLLA triblock copolymer.

[0075] (2) Weigh 1.8g of the synthesized product and dissolve it in 80mL of chloroform, filter the solution and s...

Embodiment 2

[0077] The highly gas-permeable PLD of the present embodiment 1.1 The preparation method of L copolymer film, described method specifically comprises the steps:

[0078] (1) First weigh 30g of purified L-lactide and 7.71g of PDMS (Mn: 1.1×10 4 ) (calculated by the molar ratio of the monomers) into a round-bottomed flask, and performed three gas replacements with inert argon. Pour 50mL of dried toluene into the reaction vessel, control the temperature of the oil bath to 135°C, and stir while heating. After the L-lactide and toluene are completely dissolved, add 0.12g of Sn(Oct) 2 (4 / 1000 of monomer mass), reacted for 36h. The reacted crude product was dissolved in 300 mL of chloroform, purified twice with 750 mL of n-hexane, and finally the white solid was vacuum-dried to constant weight, which was the PLLA-PDMS-PLLA triblock copolymer.

[0079] (2) Weigh 1.8g of the synthesized product and dissolve it in 80mL of chloroform, filter the solution and spread it evenly on a glas...

Embodiment 3

[0081] The highly gas-permeable PLD of the present embodiment 1.8 The preparation method of L copolymer film, described method specifically comprises the steps:

[0082] (1) First weigh 30g of purified L-lactide and 11.14g of PDMS (Mn: 1.8×10 4 ) (calculated by the molar ratio of the monomers) into a round-bottomed flask, and performed three gas replacements with inert argon. Pour 50mL of dried toluene into the reaction vessel, control the temperature of the oil bath to 140°C, and stir while heating. After the L-lactide and toluene are completely dissolved, add 0.09g of Sn(Oct) 2 (3 / 1000 of monomer mass), react for 24h. The reacted crude product was dissolved in 300 mL of chloroform, purified twice with 750 mL of n-hexane, and finally the white solid was vacuum-dried to constant weight, which was the PLLA-PDMS-PLLA triblock copolymer.

[0083] (2) Weigh 1.8g of the synthesized product and dissolve it in 80mL of chloroform, filter the solution and spread it evenly on a glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com