Detachable shaft dynamic balance tooling device for large motor

A large-scale motor and tooling technology, which is applied in the direction of electromechanical devices, electric components, and manufacturing motor generators, can solve problems such as balance deviation, workpiece scrapping, and failure to meet the high-precision requirements of nuclear power technology, so as to ensure practical performance and avoid eccentricity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

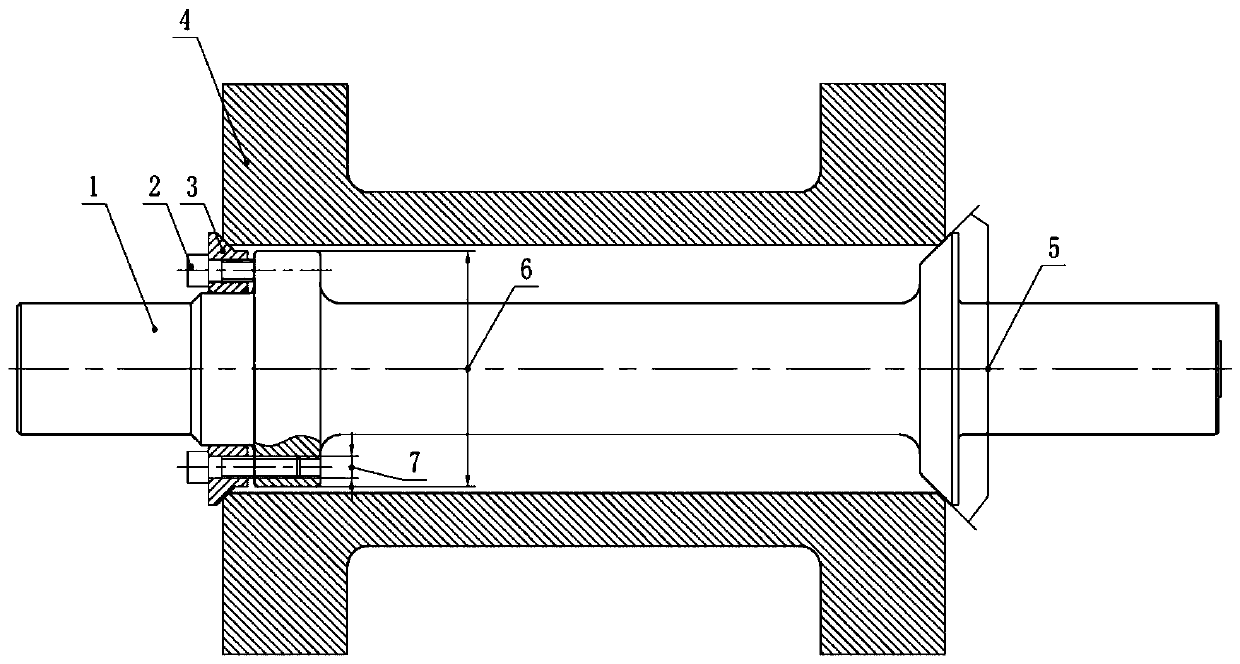

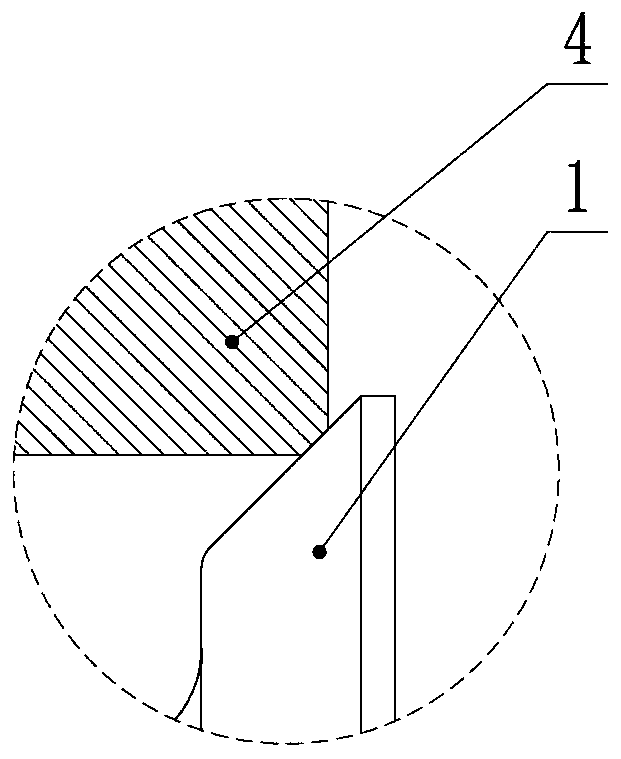

[0014] Such as figure 1 As shown, a large-scale motor detachable shaft dynamic balance tooling device is composed of a shaft 1, a tapered ring 2 and a fastening bolt 3. One end of the shaft 1 is processed with a tapered journal that matches the chamfer angle of the inner diameter end face of the detachable shaft 4. 5; The other side of the shaft 1 has a protruding large diameter 6, and the protruding part of the protruding large diameter 6 is evenly distributed on a certain pitch circle on the outer side. Threaded holes 7, fastening bolts 3 are fitted on the threaded holes 7, and the protruding There is a transition shoulder on the outer side of the protrusion with a large diameter 6, and the shaft 1 and the cone ring 2 are slidingly fitted.

[0015] The cone ring 2 is fitted on the transition shoulder of the shaft 1, and the cone ring 2 is processed on the pitch circle with the same major diameter as the shaft 1 to pass through the through hole for the fastening bolt 3 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com