CRM buck-flyback PFC converter with fixed frequency control

A converter and filter technology, used in control/regulation systems, output power conversion devices, DC power input conversion to DC power output, etc., can solve the problem of large switching frequency conversion range, complex EMI design, low power factor, etc. problem, to achieve the effect of improving PF, improving efficiency, and reducing output voltage ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

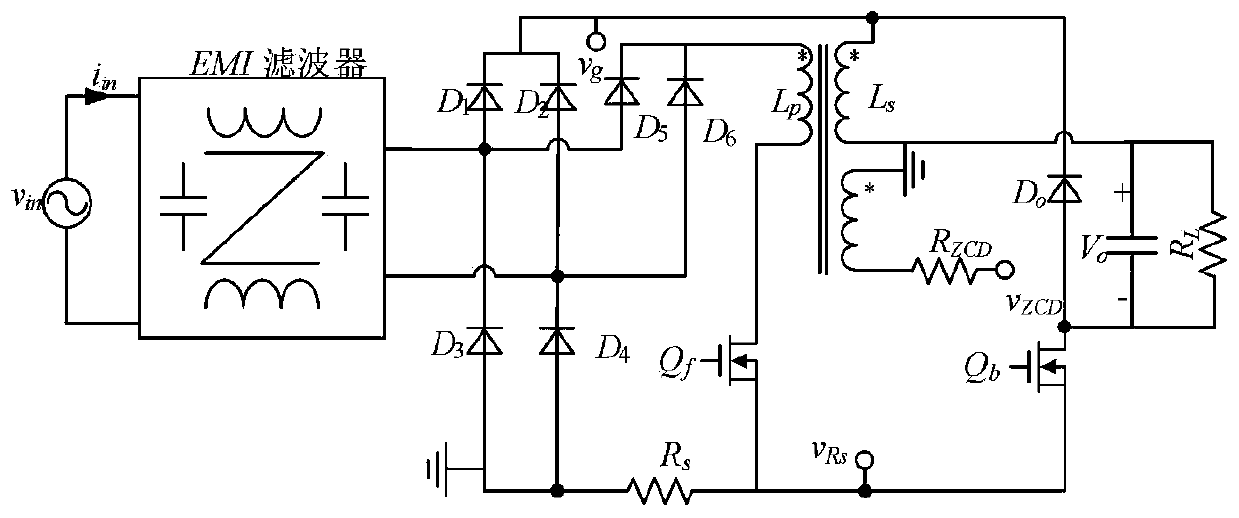

[0025] figure 1 It is the main circuit of Buck-FlybackPFC converter.

[0026] The following assumptions are made: (1) All devices are ideal; (2) The output voltage ripple is small compared to its DC value; (3) The switching frequency is much higher than the input voltage frequency.

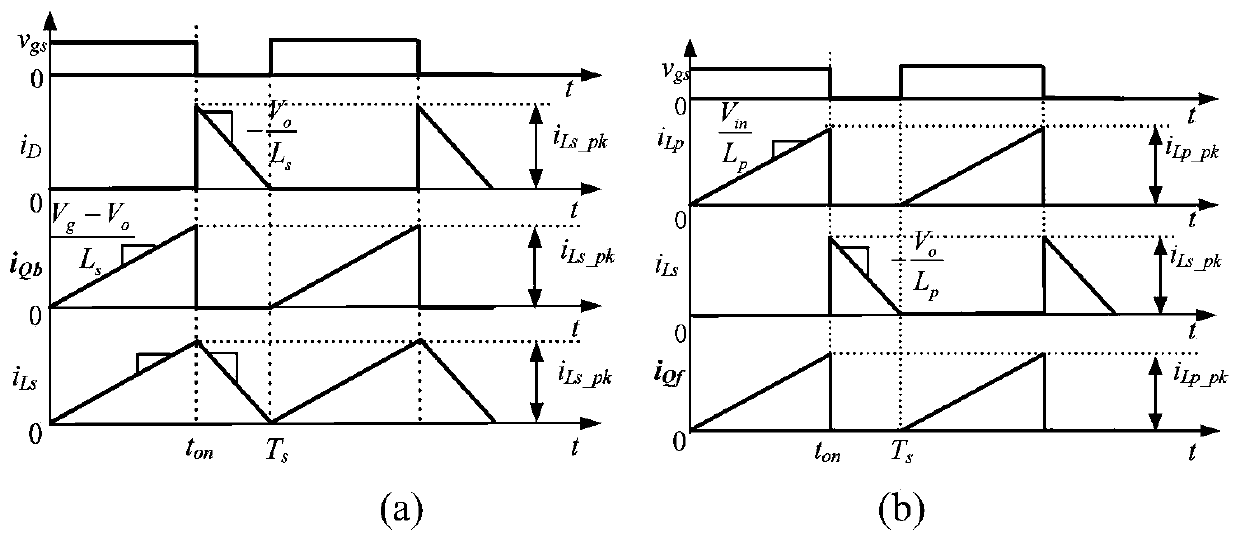

[0027] figure 2 The waveforms of the switching tube current and the inductor current in one switching cycle when the inductor current is critically continuous are given, where figure 2 (a) Waveform diagram when Buck topology works, figure 2 (b) Waveform diagram when working for the Flyback topology. When the input voltage v g less than the output voltage V o When the Flyback topology works, Q b off, Q f When turned on, D o cutoff, the inductance L p The voltage across it is v g , its current i Lp start with zero and start with v g / L p The slope rises linearly, the output filter capacitor C o supply power to the load; when Q f When turned off, according to the conservation of amp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com