A circuit control method and device

A circuit control and circuit technology, applied in the field of circuit control methods and equipment, can solve the problems of soaring bus voltage and poor circuit performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

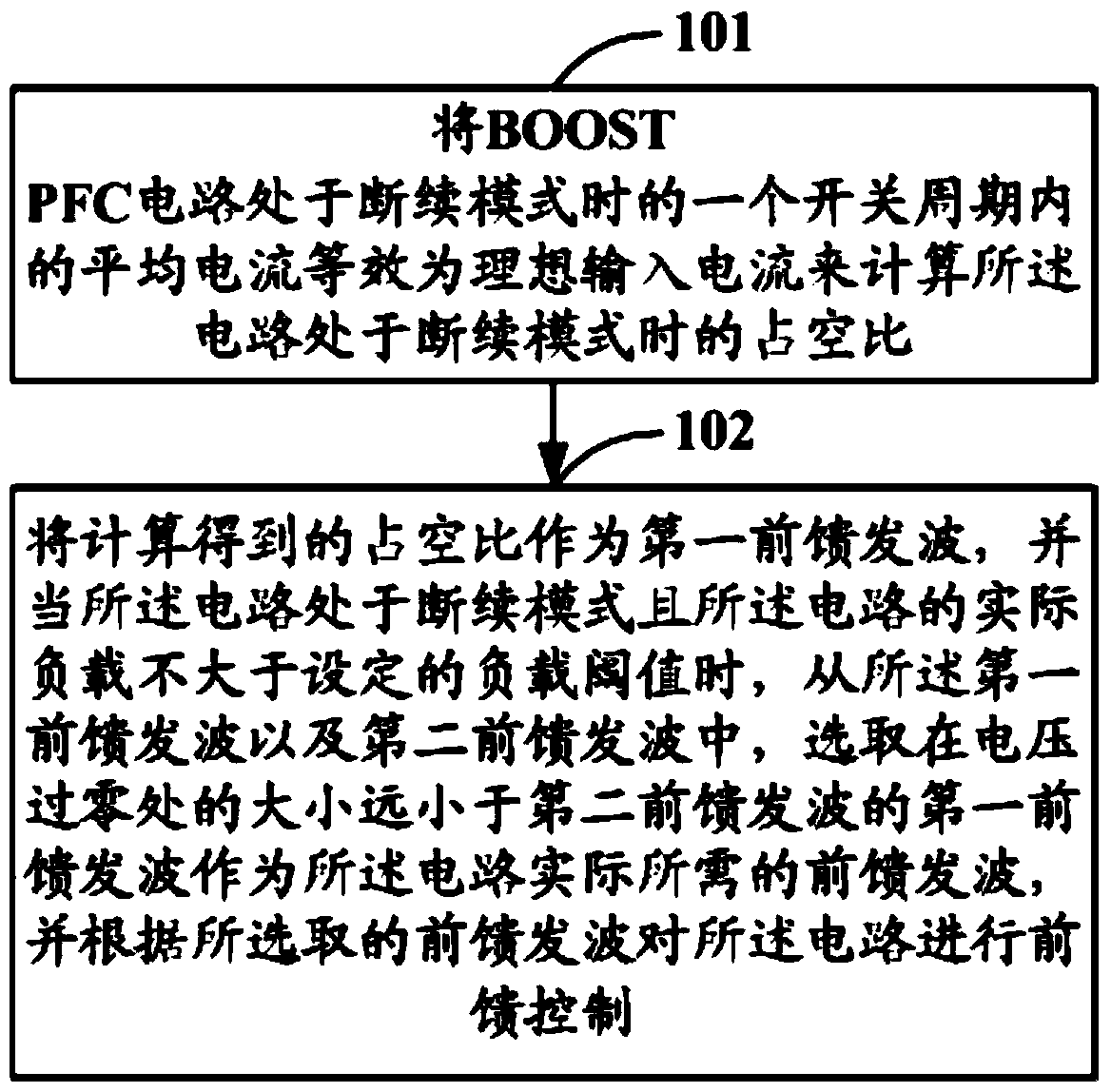

[0024] Embodiment 1 of the present invention provides a circuit control method applicable to BOOST PFC circuits, such as figure 1 As shown, it is a schematic flowchart of the circuit control method in Embodiment 1 of the present invention, and the circuit control method may include the following steps:

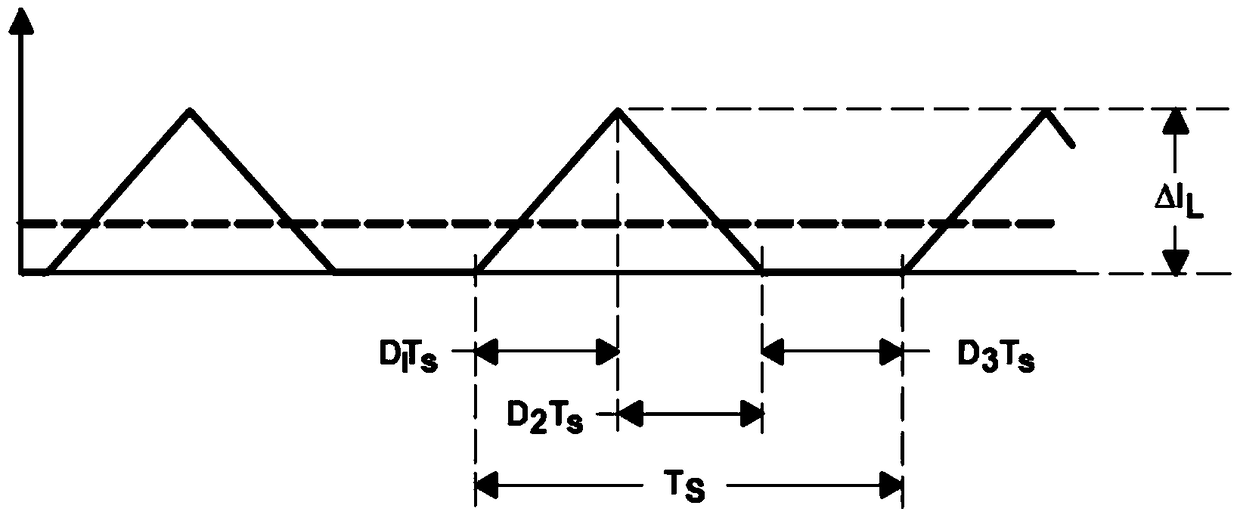

[0025] Step 101: Calculate the duty ratio when the BOOST PFC circuit is in the discontinuous mode by equating the average current in one switching cycle when the BOOST PFC circuit is in the discontinuous mode to an ideal input current.

[0026] Specifically, the BOOST PFC circuit being in the discontinuous mode means that the inductor current of the BOOST PFC circuit works in the discontinuous mode, which will not be described in detail in this embodiment of the present invention.

[0027] Step 102: Use the calculated duty cycle as the first feed-forward transmission, and when the circuit is in discontinuous mode and the actual load of the circuit is not greater than the set l...

Embodiment 2

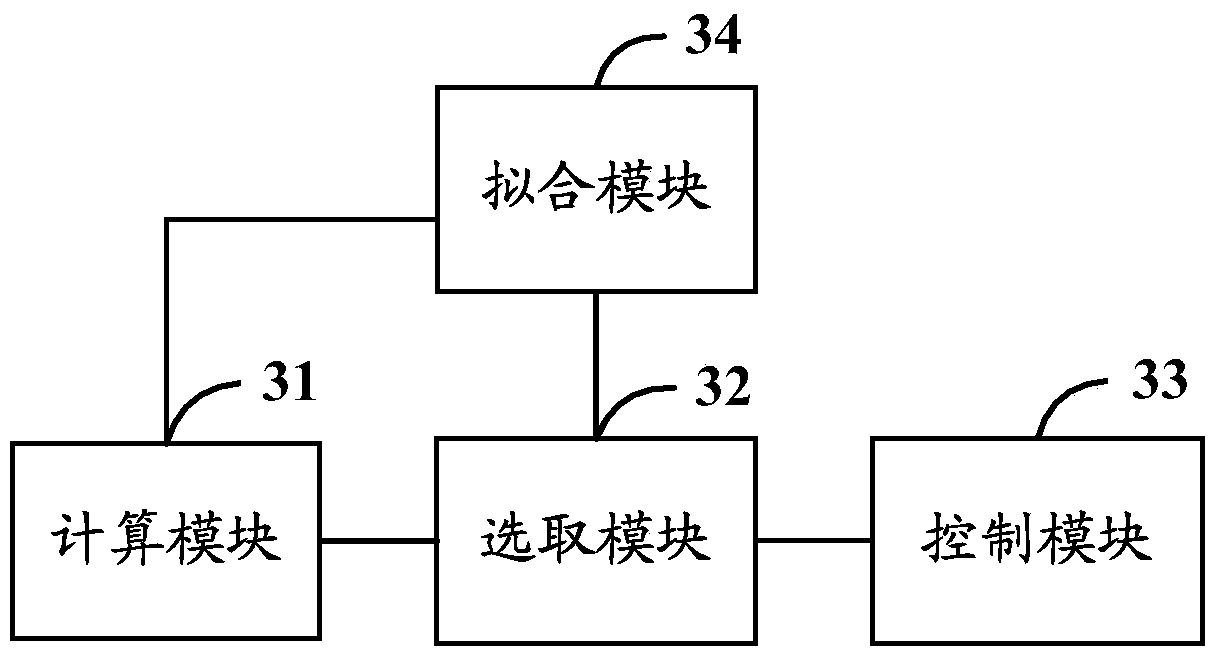

[0056] Based on the same inventive concept, Embodiment 2 of the present invention provides a circuit control device. For the specific implementation of the circuit control device, please refer to the relevant description in Embodiment 1 of the above-mentioned method. image 3 As shown, it is a schematic structural diagram of the circuit control device described in Embodiment 2 of the present invention, and the circuit control device may mainly include:

[0057] The calculation module 31 can be used to calculate the duty cycle when the BOOST PFC circuit is in the discontinuous mode by equating the average current in one switching cycle when the BOOST PFC circuit is in the discontinuous mode to an ideal input current;

[0058] The selection module 32 can be used to use the duty ratio calculated by the calculation module 31 as the first feed-forward transmission, and when it is determined that the circuit is in the discontinuous mode and the actual load of the circuit is not great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com