A method of stripping fine aggregate from the surface of waste asphalt mixture aggregate

A waste asphalt and mixture technology, applied in the direction of solid separation, etc., can solve problems such as difficult separation, difficult control of RAP gradation, and RAP cannot be reused, and achieve the effect of reducing secondary aging and increasing the addition ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details. Known components, methods and processes will not be described in detail below.

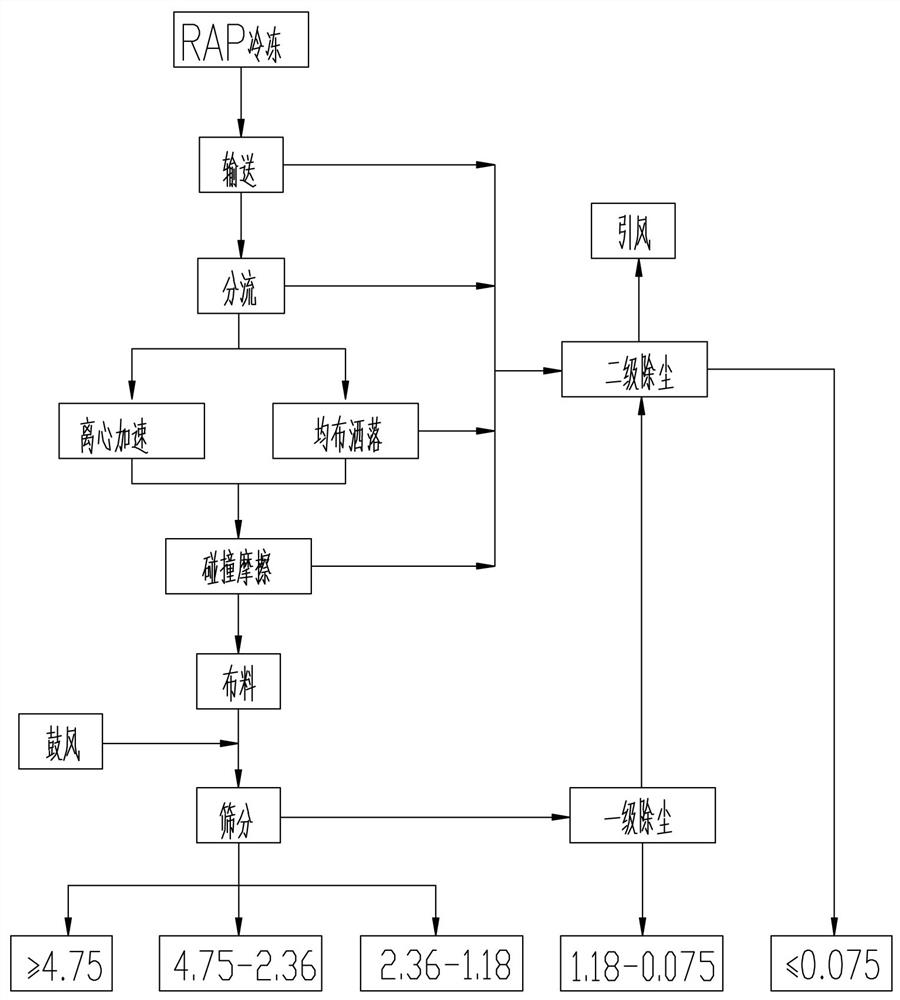

[0024] A method for stripping fine aggregate from the surface of waste asphalt mixture aggregate, refer to figure 1 , including the following steps:

[0025] 1) Use refrigeration equipment to freeze RAP to between -40°C and -10°C, and the specific temperature is adjusted according to the performance of RAP. The freezing equipment can be a common household refrigerator or a liquid nitrogen freezer in the medical field.

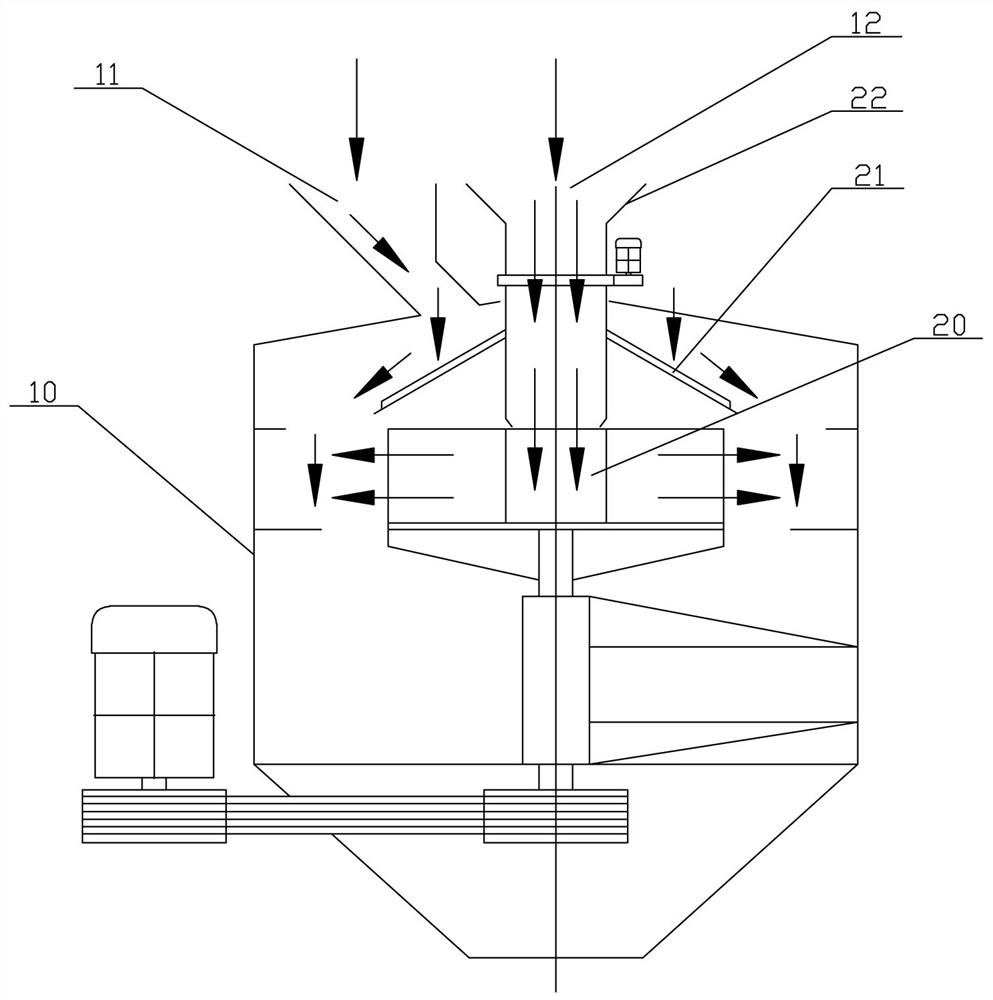

[0026] 2). Send the frozen RAP in step (1) to a special centrifugal device for centrifugation. refer to figure 2 , the special ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com