A rapid prototyping extruder for pit tube

An extruder and dimple technology, which is applied in the field of dimple tube rapid prototyping extrusion machines, can solve the problems of complex adjustment operation of dimple spacing parameters, inconvenient dimple spacing adjustment, low production efficiency, etc., to improve the dimple tube Production speed, reduce the production cost of dimpled pipe, and improve the effect of processing and production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

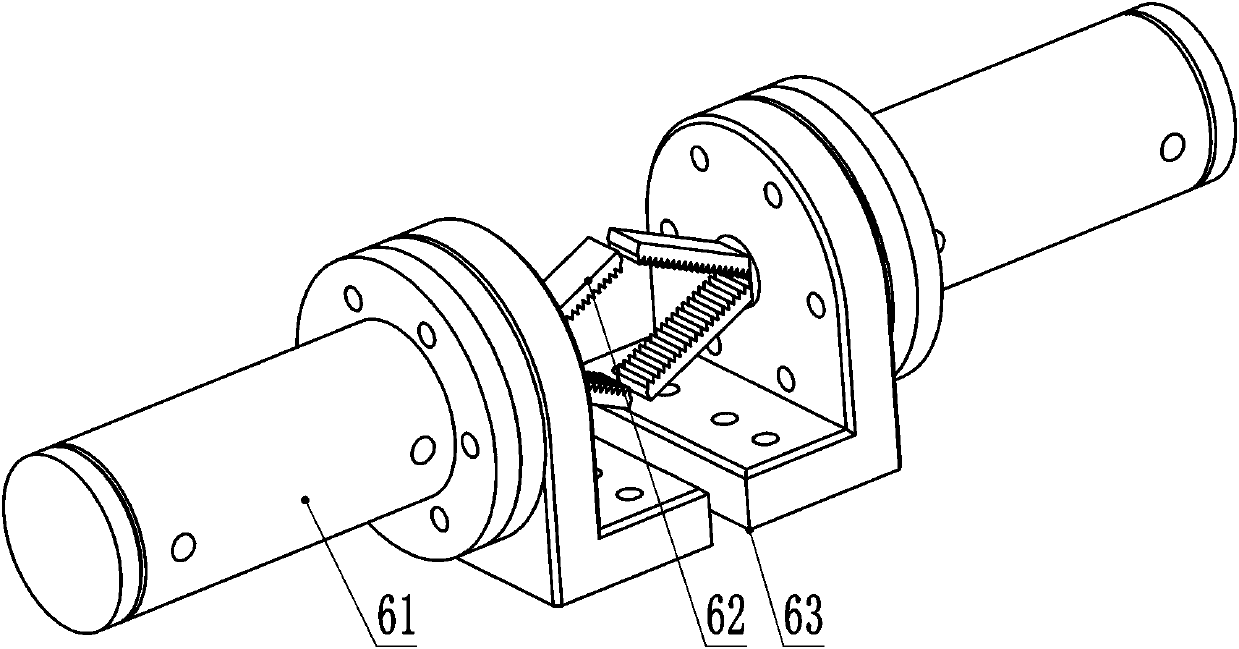

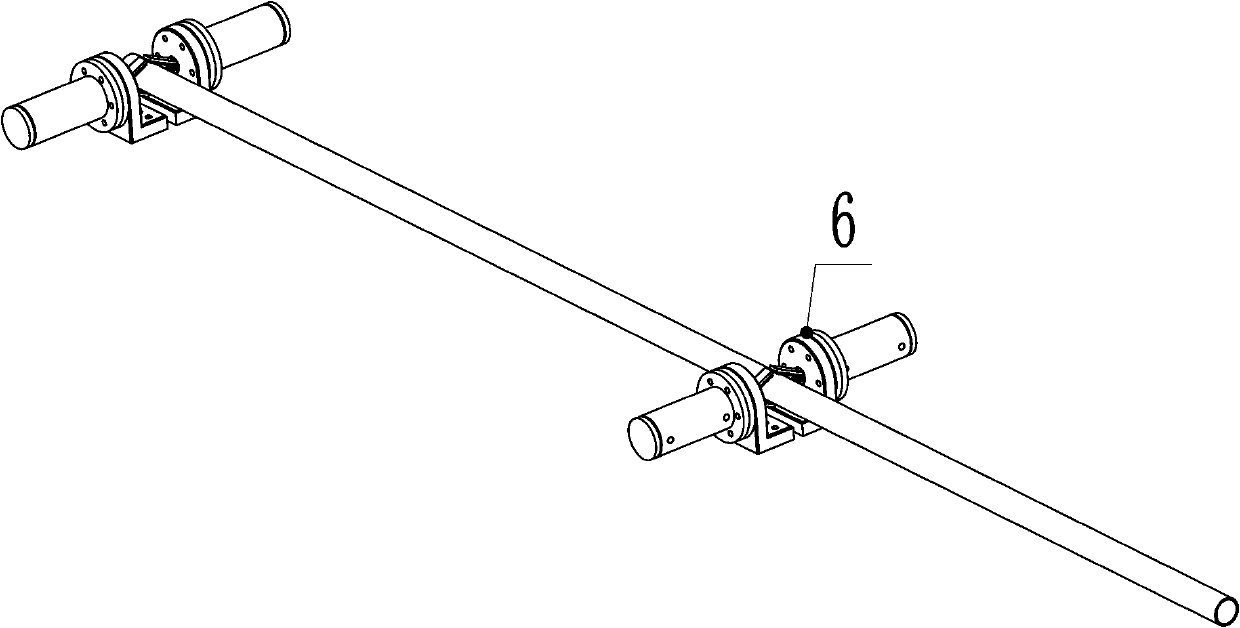

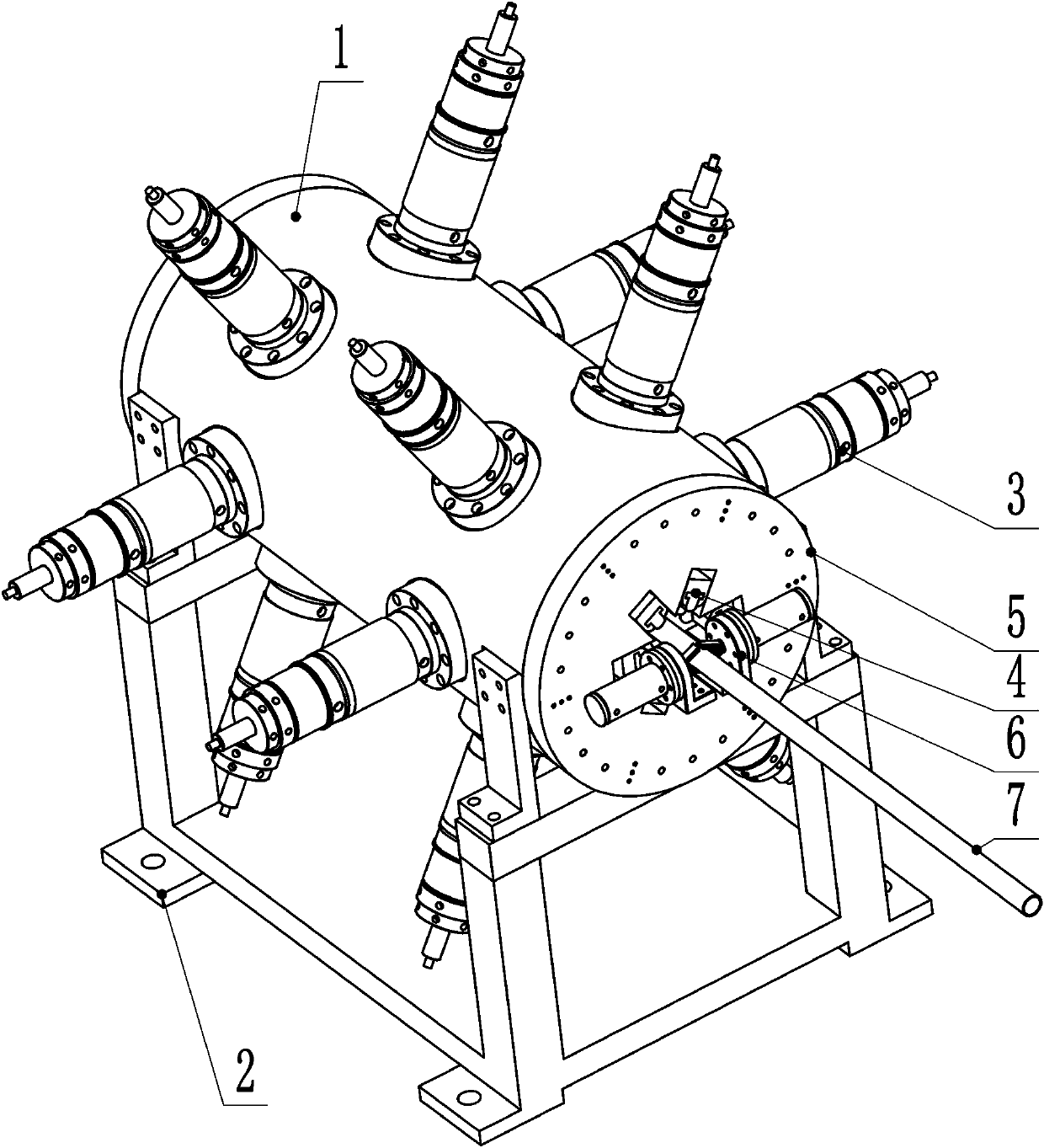

[0036] refer to Figure 1 ~ Figure 2 , a pit tube rapid prototyping extrusion machine is composed of a power system 3, a support system 1, a frame system 2, an extrusion system 4, a guide system 5, and a clamping system 6. The assembly relationship is as follows: the middle part of the top of the rack system 2 is fastened with the support system 1 through bolts, the outer surface of the support system 1 is connected with the power system 3 through bolts, and the power system 3 is connected with the extrusion system 4 through the pin shaft. The left and right ends of the pressing system 4 are respectively designed with a clamping system 6, and the jaws 62 of the clamping system 6 are in contact with pit pipes; the left and right ends of the support system 1 are respectively bolted and connected with a guide system 5. The working principle is as follows: 1. Be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com