A wall-mounted plank side grinding equipment

A wall-mounted, wooden board technology, applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of affecting the grinding effect, low sanding efficiency, and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

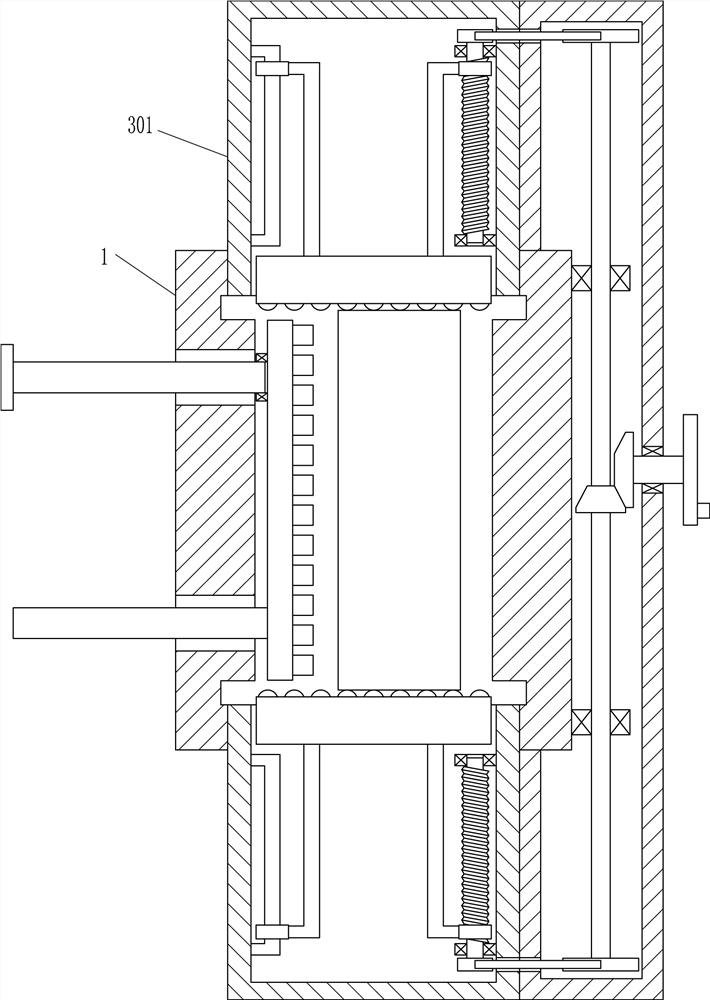

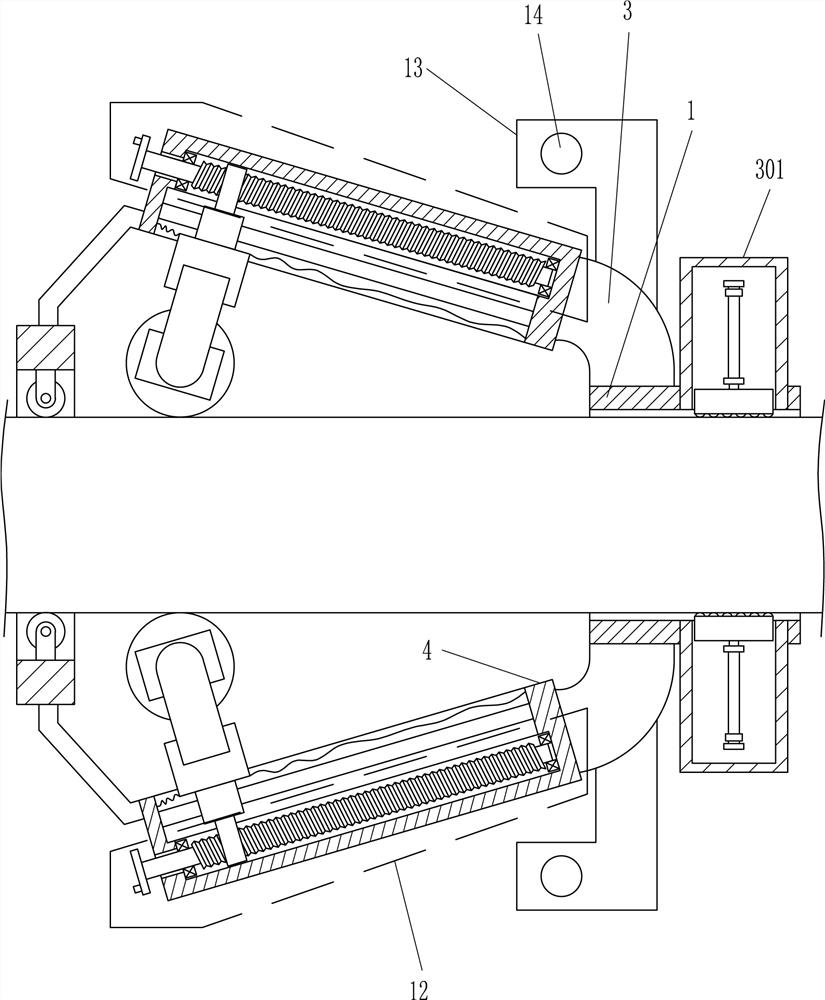

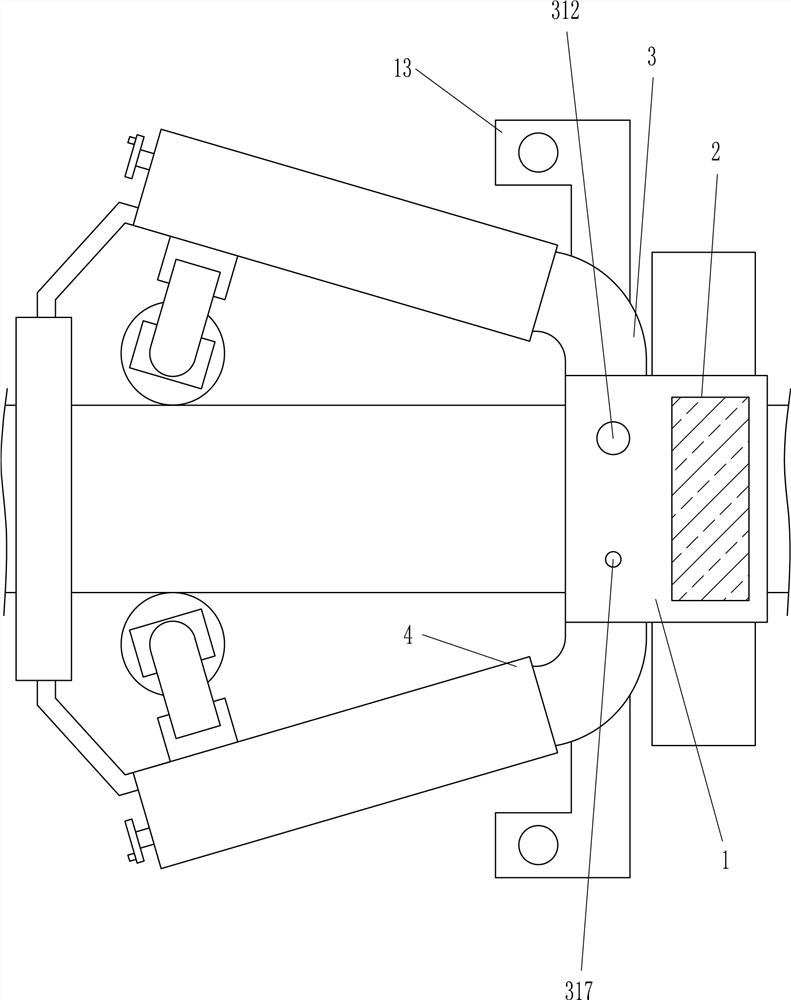

[0019] A wall-mounted side sanding device for wooden boards, such as Figure 1-3 As shown, it includes installation box 1, observation window 2, connection block 3, stroke box 4, first guide rail 5, first guide sleeve 6, moving block 7, dustproof cloth 8, installation frame 9, drive motor 10, grinding wheel 11. Adjusting device 12, wall hanging block 13 and mounting screw 14, the front right part of the installation box 1 is provided with an observation window 2, the top left side and the bottom left side of the installation box 1 are connected with a connecting block 3, and the installation box 1 passes through The way of welding connection is connected with the connection block 3, the left end of the connection block 3 is connected with the travel box 4, the inner sides of the upper and lower two travel boxes 4 are open, and the first guide rail 5 is connected between the left and right sides of the travel box 4 , the travel box 4 is connected with the first guide rail 5 by ...

Embodiment 2

[0021] A wall-mounted side sanding device for wooden boards, such as Figure 1-3 As shown, it includes installation box 1, observation window 2, connection block 3, stroke box 4, first guide rail 5, first guide sleeve 6, moving block 7, dustproof cloth 8, installation frame 9, drive motor 10, grinding wheel 11. Adjusting device 12, wall hanging block 13 and mounting screw 14, the front right part of the installation box 1 is provided with an observation window 2, the top left side and the bottom left side of the installation box 1 are connected with a connecting block 3, and the connecting block 3 The left end is connected with a travel box 4, and the inner sides of the upper and lower two travel boxes 4 are open. The first guide rail 5 is connected between the left and right sides of the travel box 4, and the first guide rail 5 is slidably connected with a first guide sleeve. 6. The inner side of the upper and lower first guide sleeves 6 is connected with a moving block 7, an...

Embodiment 3

[0024] A wall-mounted side sanding device for wooden boards, such as Figure 1-5 As shown, it includes installation box 1, observation window 2, connection block 3, stroke box 4, first guide rail 5, first guide sleeve 6, moving block 7, dustproof cloth 8, installation frame 9, drive motor 10, grinding wheel 11. Adjusting device 12, wall hanging block 13 and mounting screw 14, the front right part of the installation box 1 is provided with an observation window 2, the top left side and the bottom left side of the installation box 1 are connected with a connecting block 3, and the connecting block 3 The left end is connected with a travel box 4, and the inner sides of the upper and lower two travel boxes 4 are open. The first guide rail 5 is connected between the left and right sides of the travel box 4, and the first guide rail 5 is slidably connected with a first guide sleeve. 6. The inner side of the upper and lower first guide sleeves 6 is connected with a moving block 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com