Polishing pad cleaning method and device

A technology for cleaning devices and polishing pads, applied in cleaning methods and tools, abrasive surface adjustment devices, cleaning methods using tools, etc., can solve the problems of scratches on the wafer surface, particles falling on the polishing pad, residues, etc., to achieve Avoid scratching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

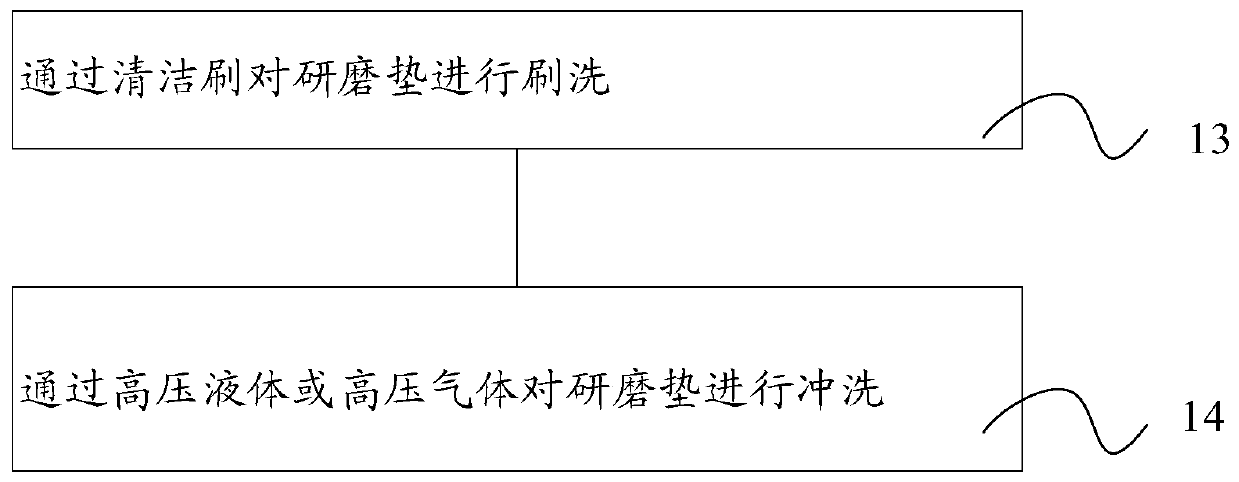

[0023] Please refer to figure 1 , an embodiment of the present invention provides a method for cleaning a polishing pad, comprising:

[0024] Step 10, before the wafer is polished, the polishing pad is washed with high-pressure liquid or high-pressure gas, and the polishing pad is brushed with a cleaning brush.

[0025] Step 20, after the wafer is ground, the polishing pad is scrubbed with a cleaning brush.

[0026] The high-pressure liquid may be water such as pure water.

[0027] Please refer to Figure 4 , the embodiment of the present invention also provides a polishing pad cleaning device, including a flushing device 1 for cleaning the polishing pad and a brushing device 2 for cleaning the polishing pad. The grinding pad 3 is arranged on a rotating table 4 of the grinding equipment, and the rotating table 4 is rotated by a rotating shaft 5 . Wherein the flushing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com