A combination of water film cavitation and deicing fluid anti-deicing fairing

A technology of deicing fluid and fairing, which is applied to deicing devices, aircraft power units, aircraft power device components, etc., and can solve problems such as complex devices, large energy consumption, and large thermal inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

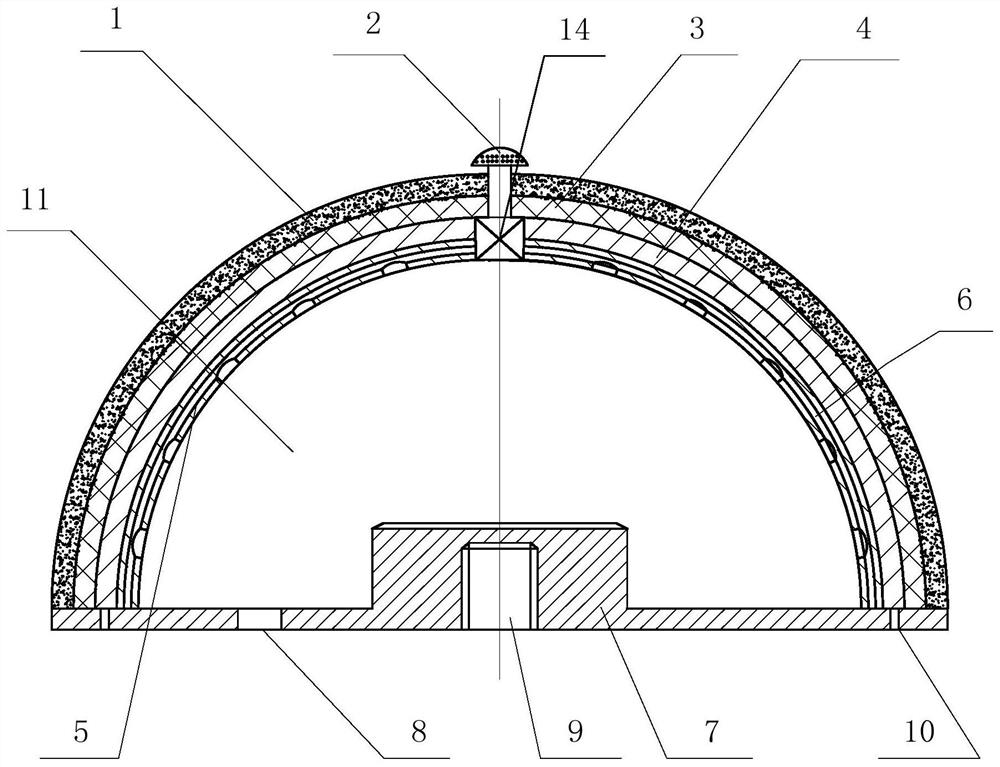

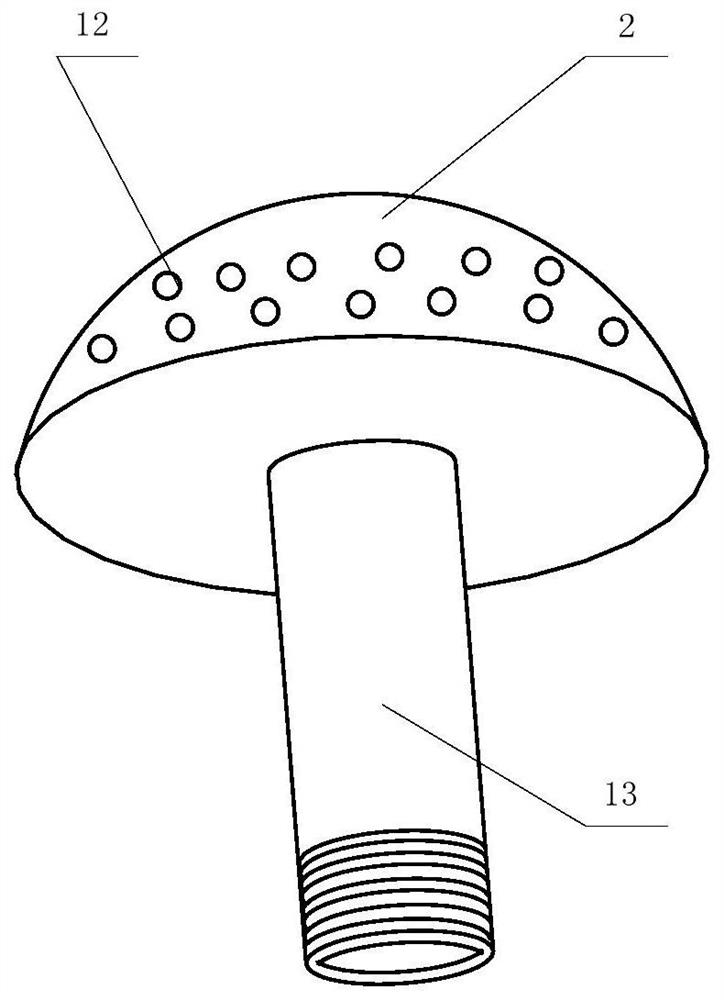

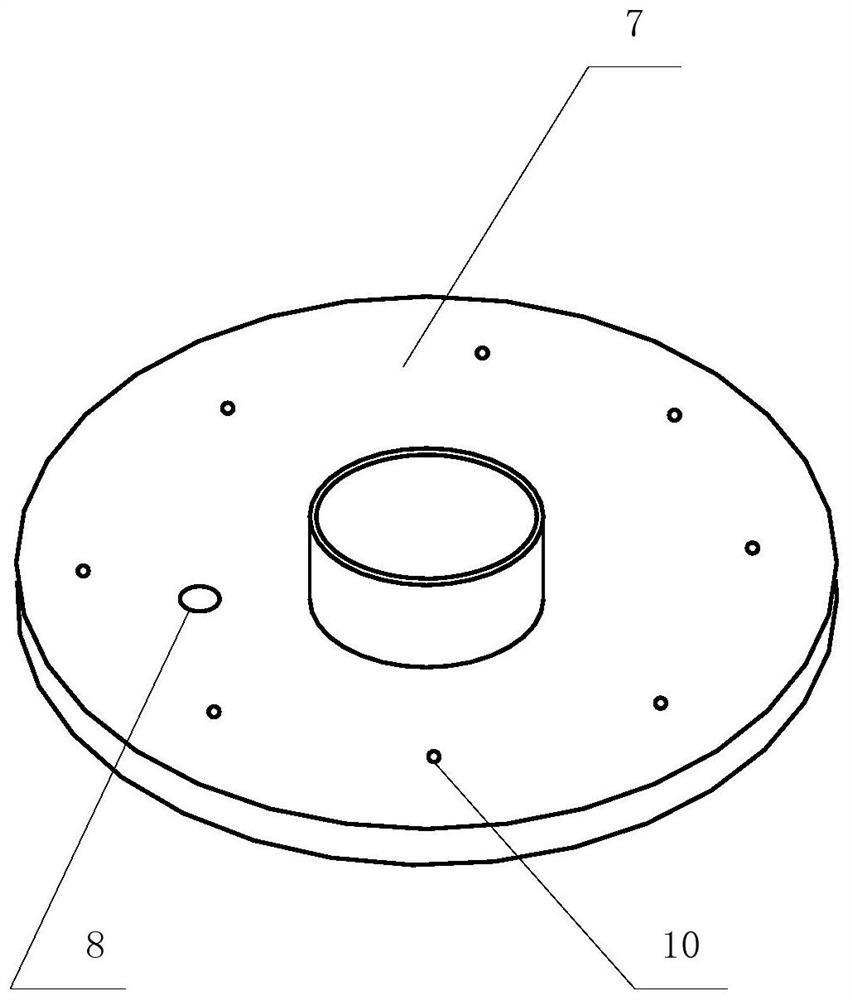

[0038] First of all, the present invention discloses a water film cavitation and deicing liquid combined anti-deicing fairing, which can be used for aircraft aeroengines, including a fairing skin 3, a heating part, a cavitation bubble generation layer 1, and a deicing liquid flow Road cover 5, deicing liquid nozzle 2 and disc-shaped part 7, wherein, the heating part is located inside the fairing skin 3, the cavitation bubble generation layer 1 is located outside the fairing skin 3, and the deicing liquid flow channel cover 5 is located The inner side of the heating part has a deicing fluid channel cavity 6; the deicing fluid nozzle 2 is connected with the deicing fluid channel cover 5, and the outlet 12 of the deicing fluid nozzle 2 passes through the fairing skin 3, and the deicing fluid The deicing fluid sprayed by the nozzle 2 can form a cavitation bubble generation layer 1 on the outside of the fairing skin 3; the periphery of the disk-shaped part 7 is connected to the cowl...

Embodiment 2

[0054] Embodiment 2 discloses a kind of deicing method of aero-engine, uses water film cavitation as described in embodiment 1 and deicing fluid joint anti-deicing fairing, comprises the following steps:

[0055] 1) Add deicing fluid into the cavity;

[0056] 2) The fairing rotates at high speed during flight, and the deicing fluid enters the deicing fluid channel cover 5 through the centrifugal force generated by the high speed rotation of the fairing, and flows through the deicing fluid channel cavity 6 to the deicing fluid nozzle2;

[0057] 3) The deicing fluid nozzle 2 sprays the deicing fluid heated by the electric heating pad 4 to form a water film during the anti-icing process, and the deicing fluid promotes the reaction of the cavitation bubble generation layer 1 to generate bubbles, and the bubbles are Water conservancy cavitation occurs inside the water film due to the difference in internal and external air pressure, and cavitation energy is released for anti-icing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com