Barreled water bottle cap reverse cap removing device

A technology of rejecting device and water bottle, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of wasting manpower, small differences in the structure of bottle caps, unable to guarantee the rejection rate and no missed inspections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

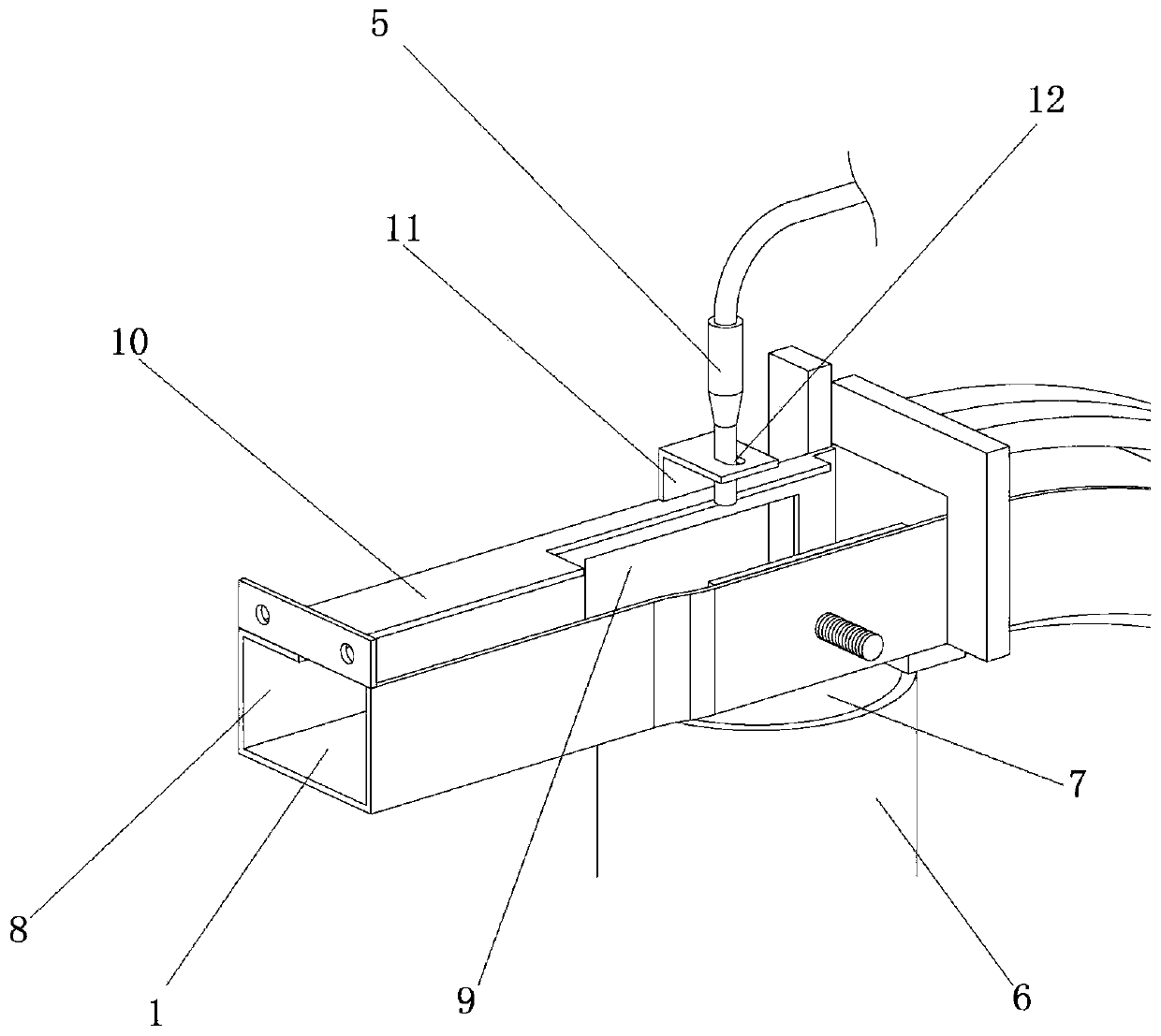

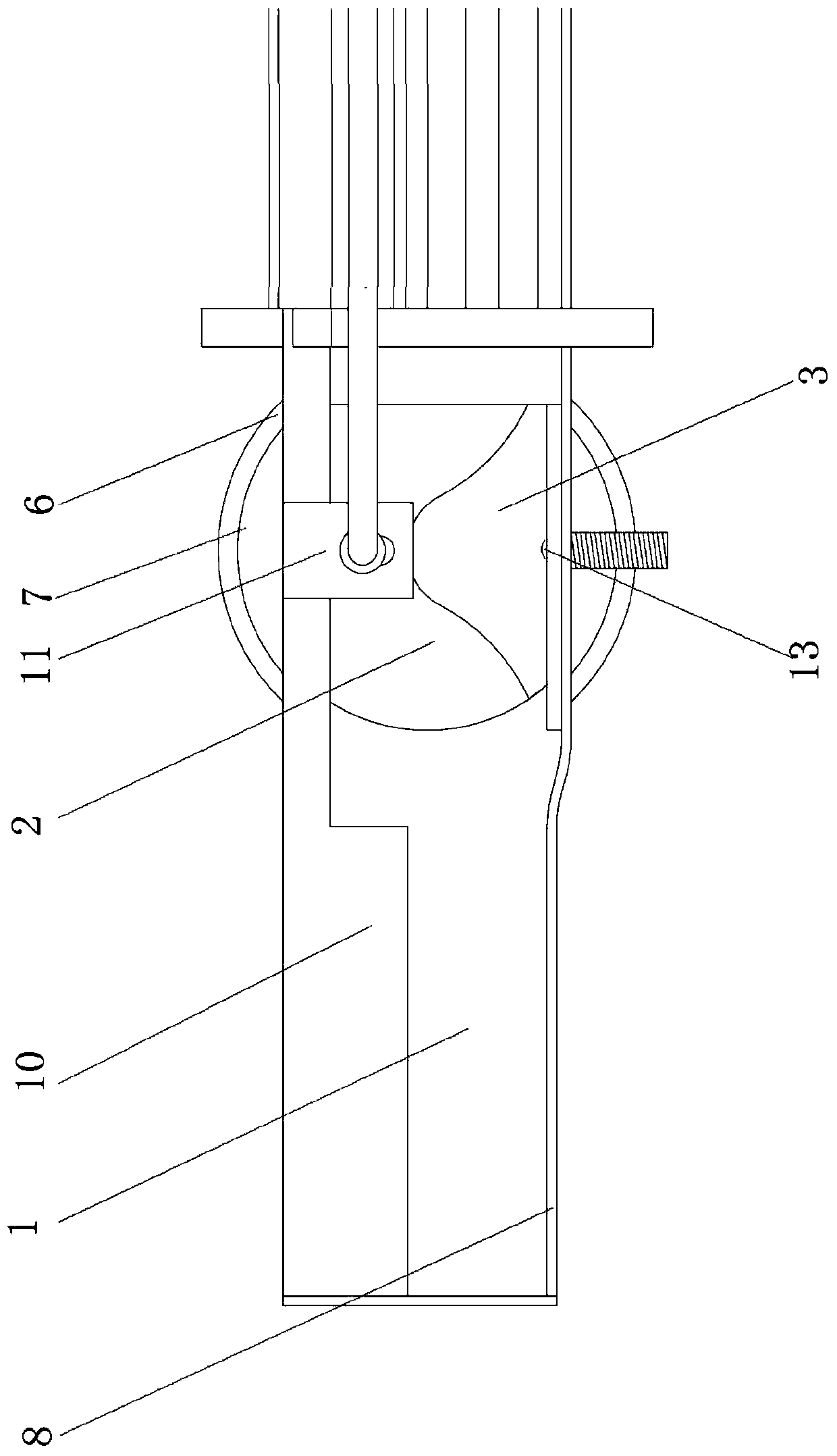

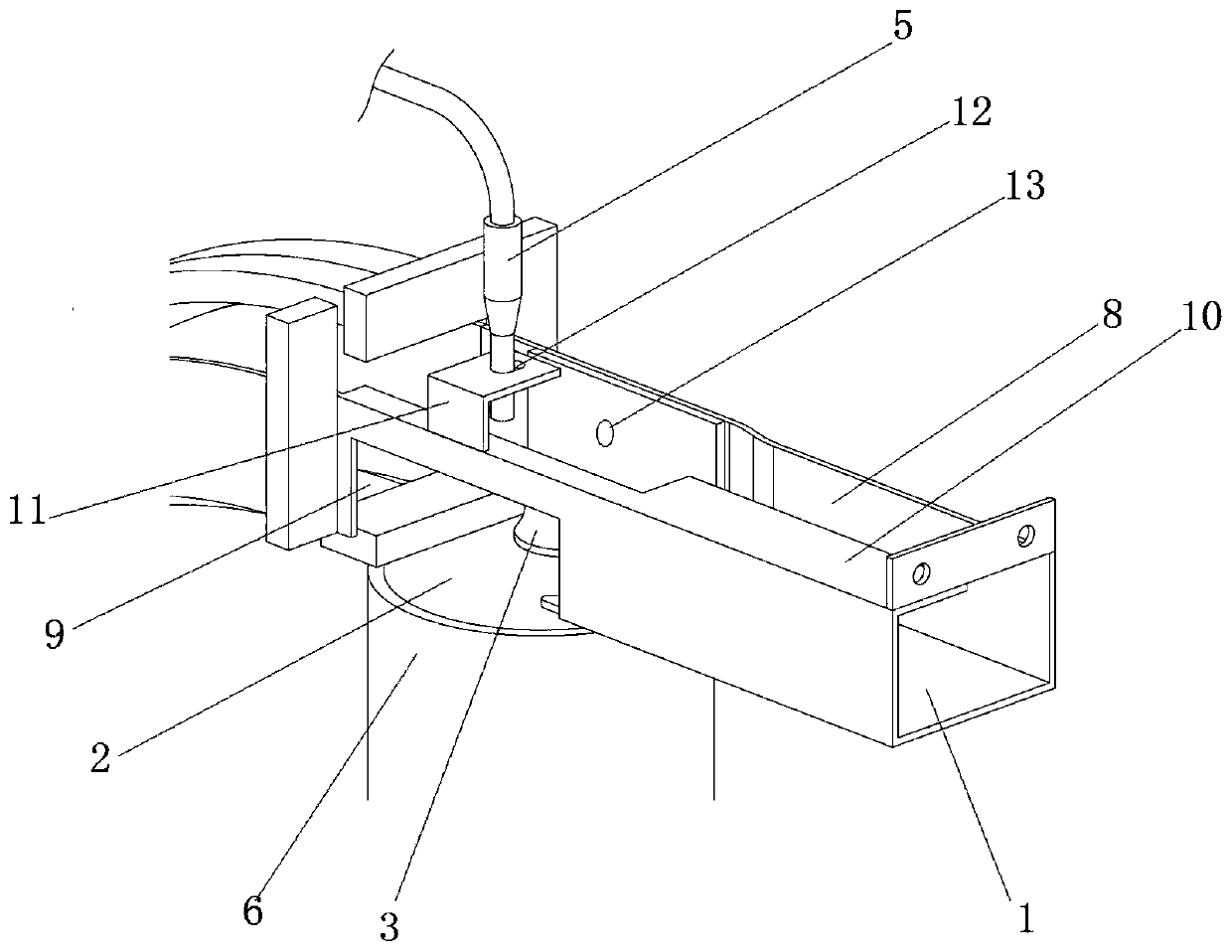

[0025] Embodiment 1: A kind of barreled water bottle cap reverse cap rejecting device, such as Figure 1-7 As shown, it is installed on the transmission path at the exit of the cap unscrambling machine. A crescent-shaped slot 2 is provided on the bottom surface of the transmission slide track 1. The arc diameter of the crescent-shaped slot 2 is not less than the diameter of the cap surface of the bottle cap 4. A support plane 3 is left on the bottom surface of the transmission slide track 1 in the middle of the crescent-shaped slot 2, and the length of the support plane 3 extending to the middle of the crescent-shaped slot 2 is not less than the radius length of the bottle cap 4 cover surface. A rejecting air nozzle 5 is arranged directly above the center of the groove surface of the groove 2, and the rejecting air nozzle 5 blows airflow directly below. A capping pipe 6 is installed below the cap sorting machine, and a pipe opening 7 of 6 capping pipes is arranged directly bel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap