A Boundary Body Sectional Preloading Construction Method for Friction-type Cast-in-situ Pile in Karst Area

A construction method and technology in karst areas, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as inability to ensure the quality of cast-in-situ piles, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

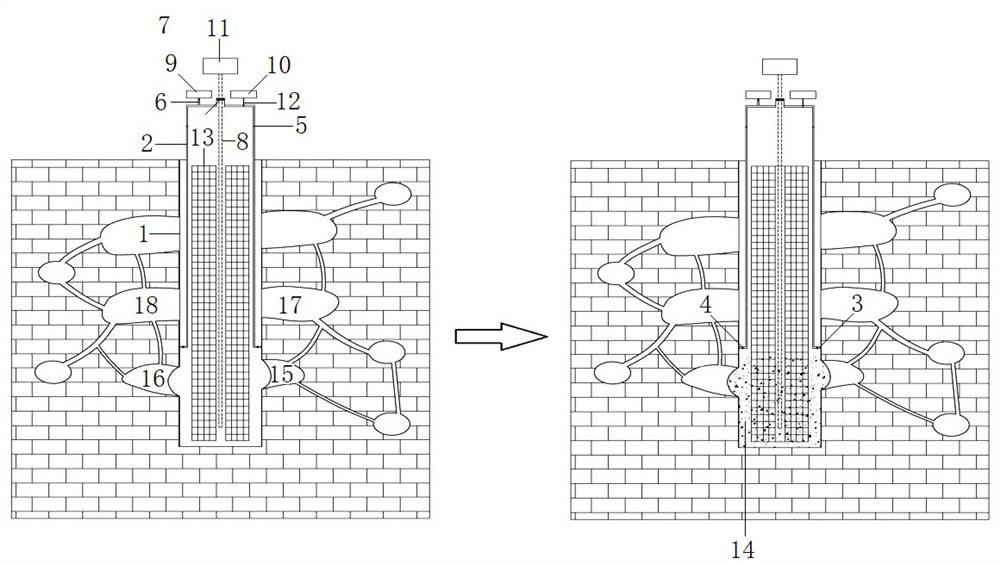

[0017] Embodiment: In this embodiment, the boundary body segmental preloading construction method for friction-type cast-in-situ piles in karst areas first cuts off the boundary body 1 and then pressurizes the pile foundation holes in the karst area, thereby controlling the boundary body 1 The ductility in each karst cave can improve the pile body friction of the cast-in-situ pile.

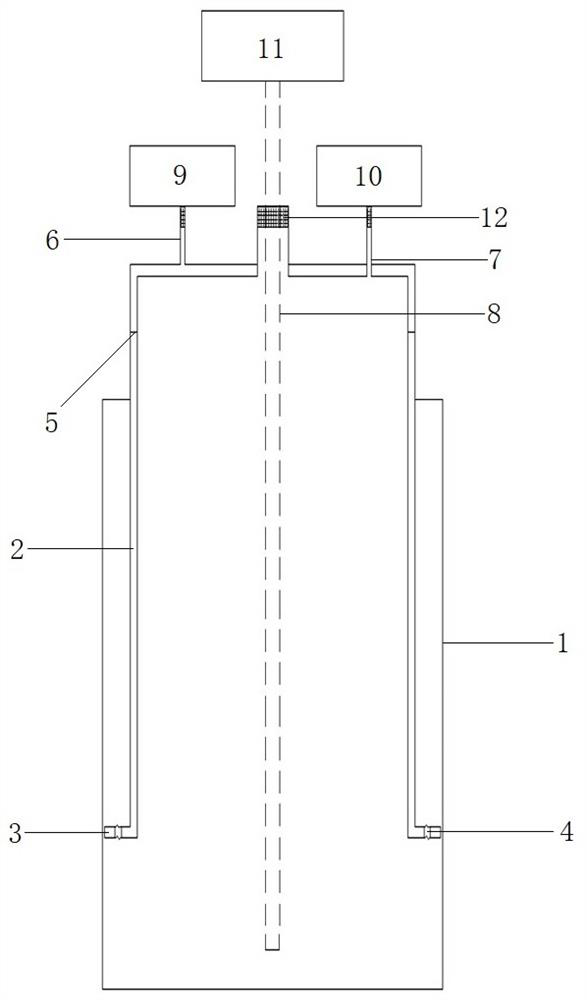

[0018] Such as figure 1 and figure 2 As shown, the segmented preloading device involved in the segmented preloading construction method includes an inflatable cavity 2 , a main charging tube 6 and an auxiliary charging tube 7 .

[0019] Among them, such as figure 2 As shown, due to geological reasons, the pile foundation holes in the karst area will run through multiple karst caves. In order to prevent the concrete from directly diffusing into the karst caves when the pouring piles are poured in the later stage, causing unevenness, a boundary body 1 is placed on the inner wall of the pile foun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com