Servo quantifying machine

A frame and linear motor technology, applied in the field of machinery, can solve the problems of not being able to accurately control the amount of glue delivered, and the glue delivery device cannot achieve quantitative glue delivery, etc., and achieve the effect of controlling the speed of glue delivery and accurate glue delivery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

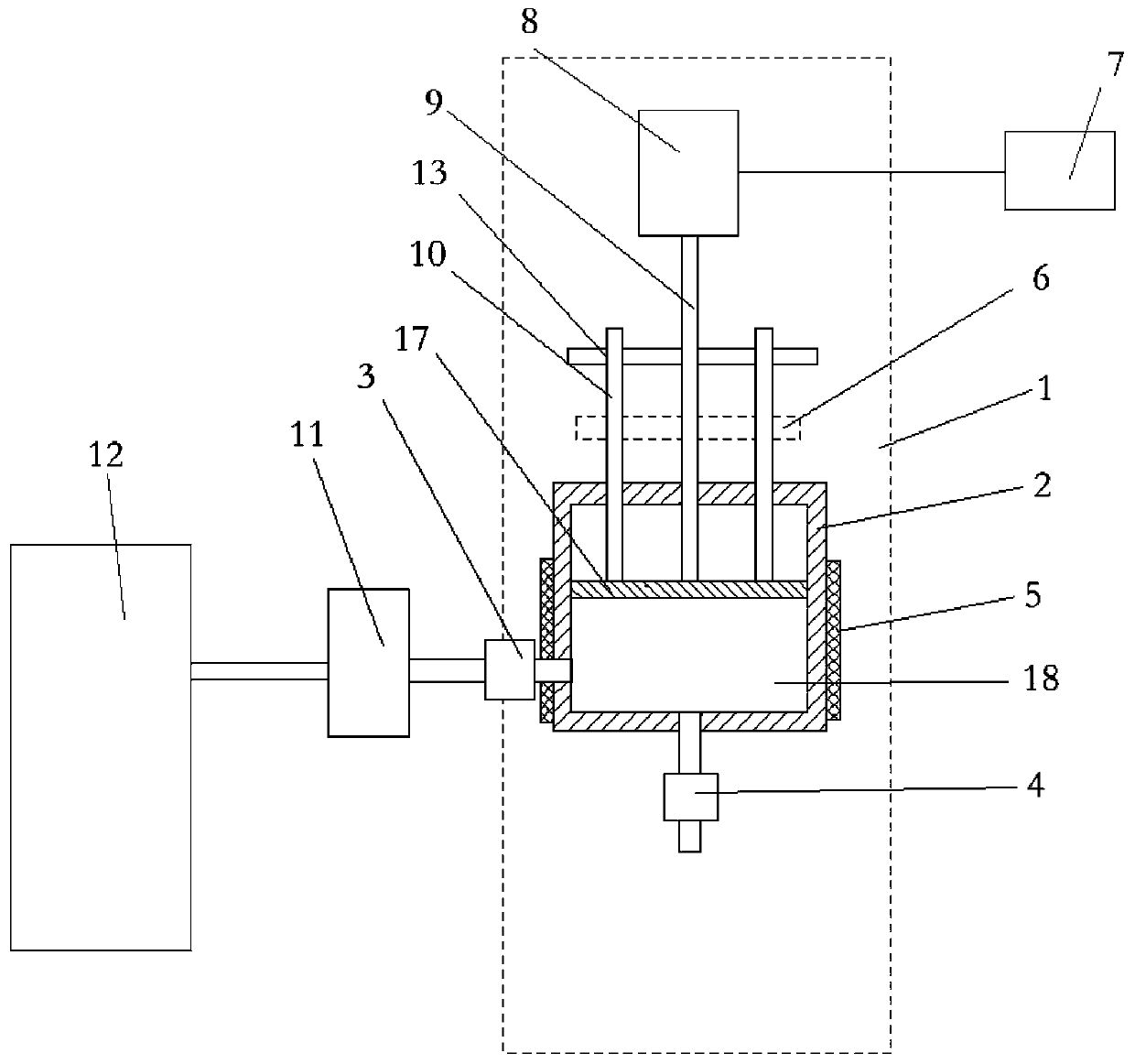

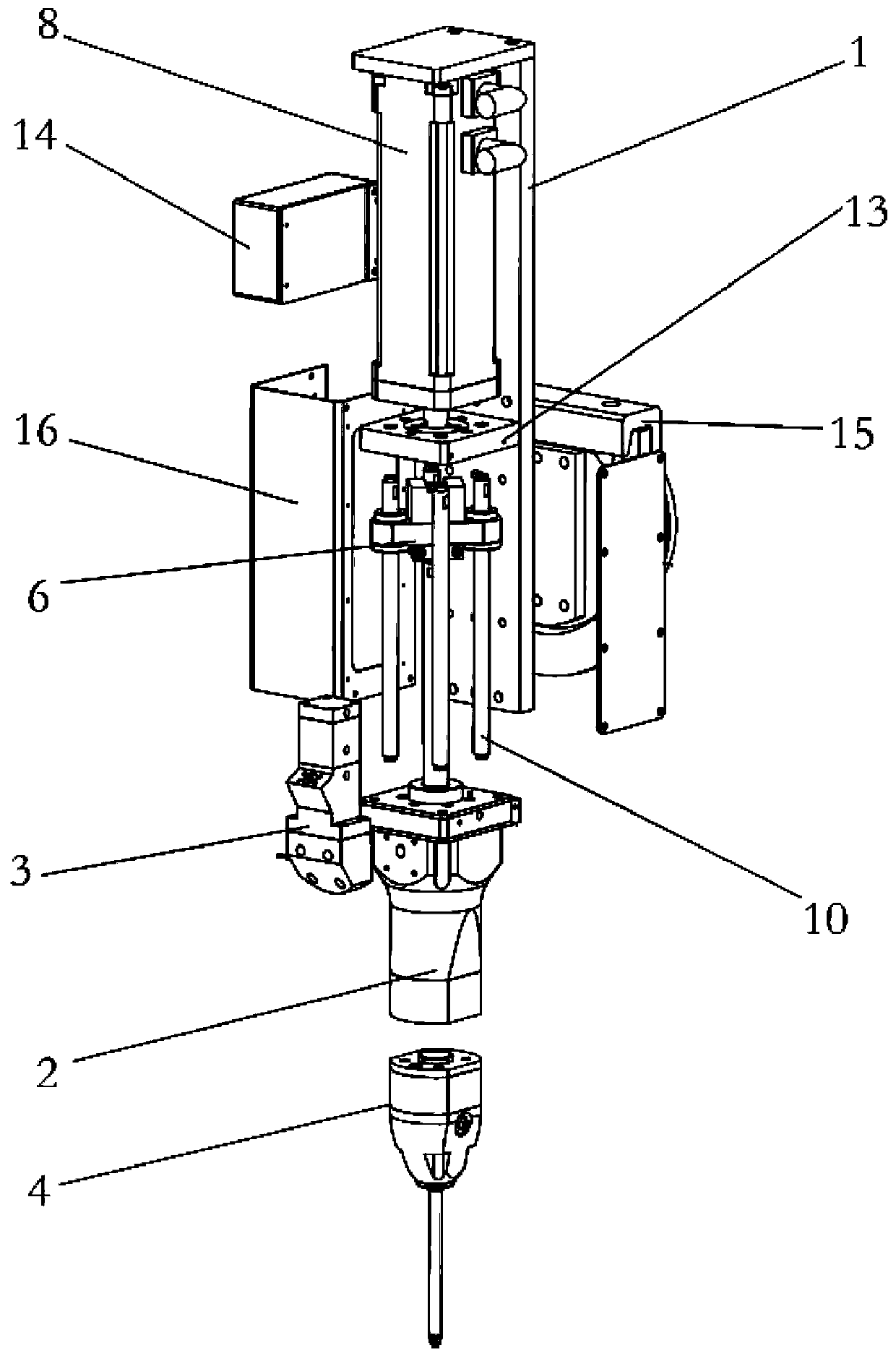

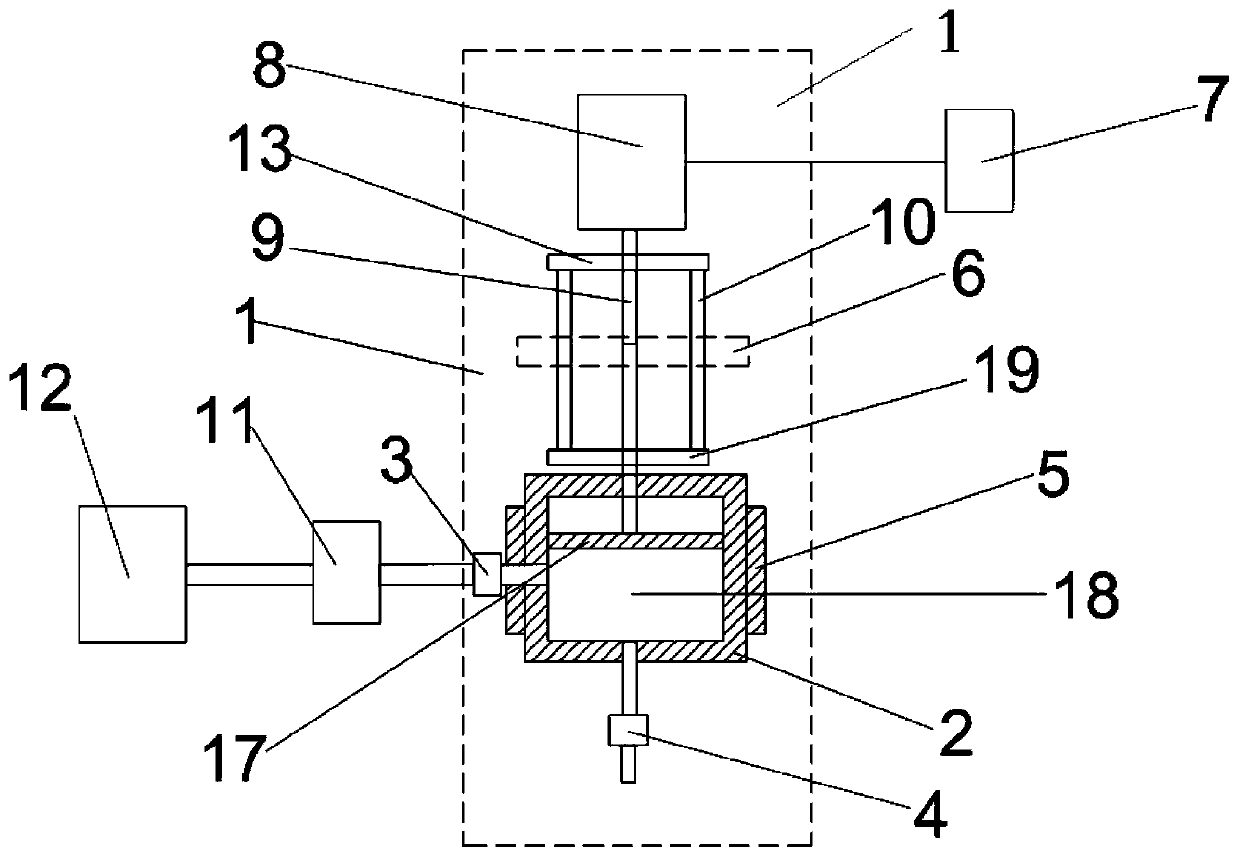

[0015] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-Figure 3 As shown, the frame 1 is provided with a glue chamber 2, and the cavity 18 of the glue chamber is connected with the glue inlet valve 3 and the glue outlet valve 4 respectively; a valve body 17 is arranged in the cavity 18, and one end of the valve body 17 is connected to The piston rod 9 is connected, and the upper end of the piston rod 9 is connected with the output end of the linear motor 8; the glue chamber 2 and the lower guide seat 19 are fixedly connected by screws, and the two ends of the guide rod 10 are sleeved on the upper and lower guide seats 13. In the guide hole of the guide seat 19; the upper guide seat 13 and the lower guide seat 19 are fixed on the frame 1; the linear motor 8 is connected with the servo driver 7; the glue inlet valve 3 is connected with the glue pump 11, The glue pump 11 is connected with a glue storage tank 12 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com