Separation construction method for mass concrete foundation unit

A large-volume concrete and basic unit technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problem of construction disturbance from 7:00 to 9:00 in the morning and from 17:00 to 19:00 in the evening (22:00 to 6:00 in the evening, Limited supply and other issues, to achieve the effect of reducing temperature shrinkage and drying shrinkage, avoiding harmful cracks, and satisfying compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The invention provides a construction method suitable for large-volume concrete foundation units in various industrial and civil buildings, mainly including construction preparation, construction joint design, erecting steel bars and formwork, concrete pouring construction, concrete finishing and curing, concrete temperature monitoring and other processes.

[0029] 1. Construction preparation

[0030] 1. Positioning and setting out;

[0031] 2. Mass concrete foundation unit separation construction sequence

[0032] Divide the mass concrete foundation into N units, and design the pouring sequence according to the principle that adjacent units can be connected into a whole after 7 days;

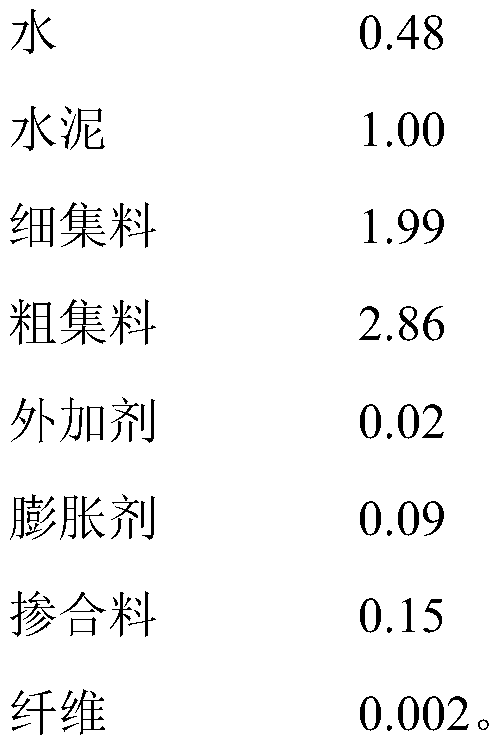

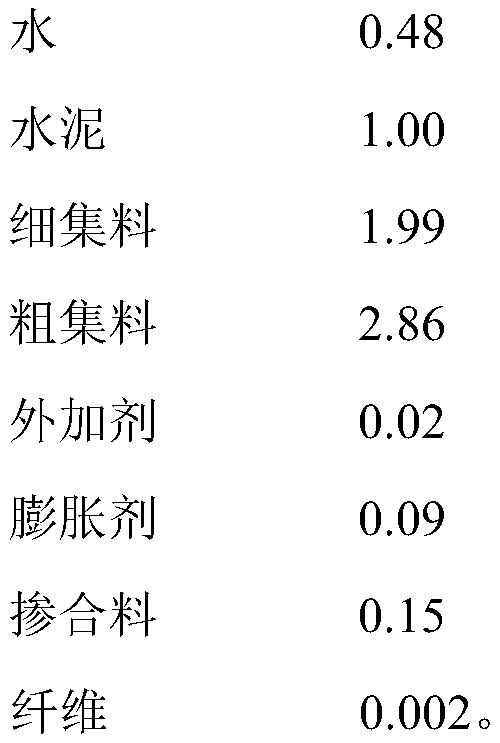

[0033] 3. Preparation of concrete

[0034] The principle of concrete material control and mix ratio design is to increase the tensile and demolition strength as much as possible under the condition of ensuring that the compressive strength meets the requirements, and at the same time ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap