Rotary wheel and turbine dual-power steam turbine

A steam turbine and dual-power technology, applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of high heat energy consumption, small mechanical energy, and more mechanical energy, and achieve high power, large mechanical energy, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

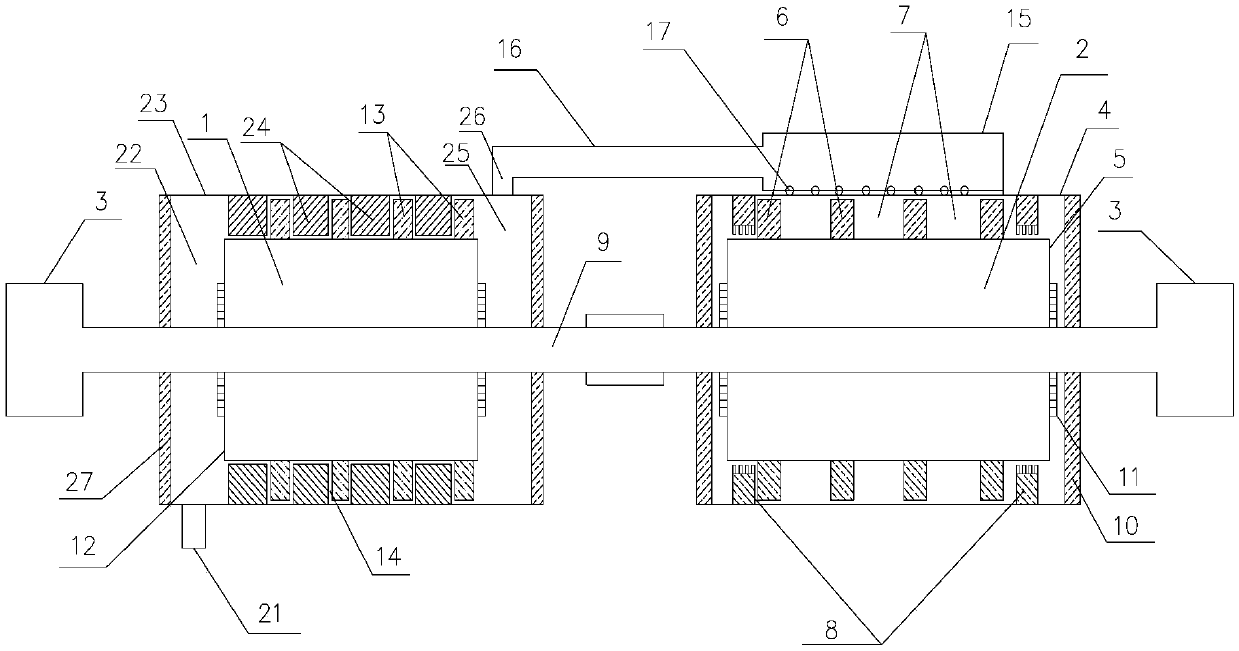

[0025] The present invention will be further described below in conjunction with accompanying drawing.

[0026] figure 1 Shown is a structural diagram of an embodiment of the present invention. A rotary wheel and turbine dual-power steam turbine, comprising a rotary turbine 1 and a turbine 2 rotating around the same rotating shaft (9), the rotary turbine 1 and the turbine 2 are connected through a gas delivery pipe 16, and are respectively arranged at the left and right ends of the rotary shaft 9 There is a generator 3 that is connected to the rotary machine 1 and the turbine 2, so that the mechanical energy generated by each can be matched and supplemented to each other, so as to achieve the sharing of mechanical energy.

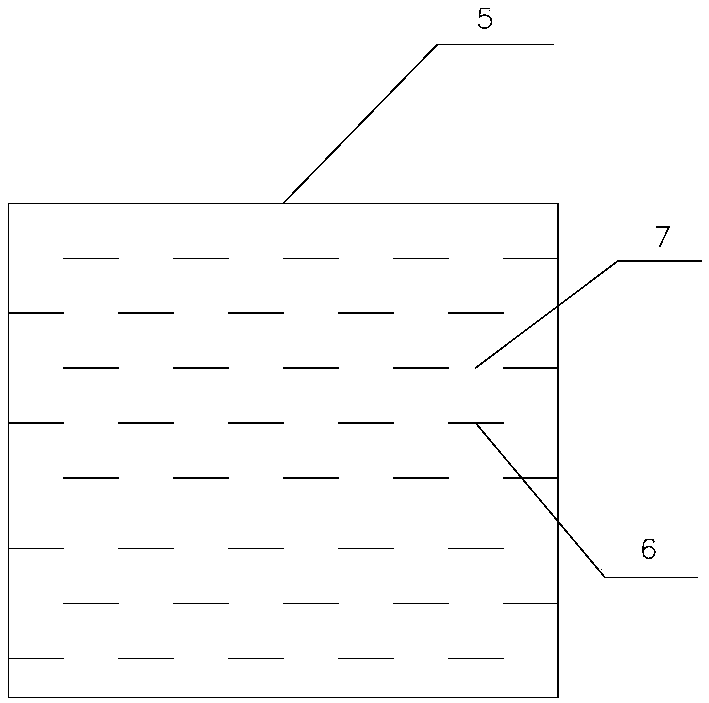

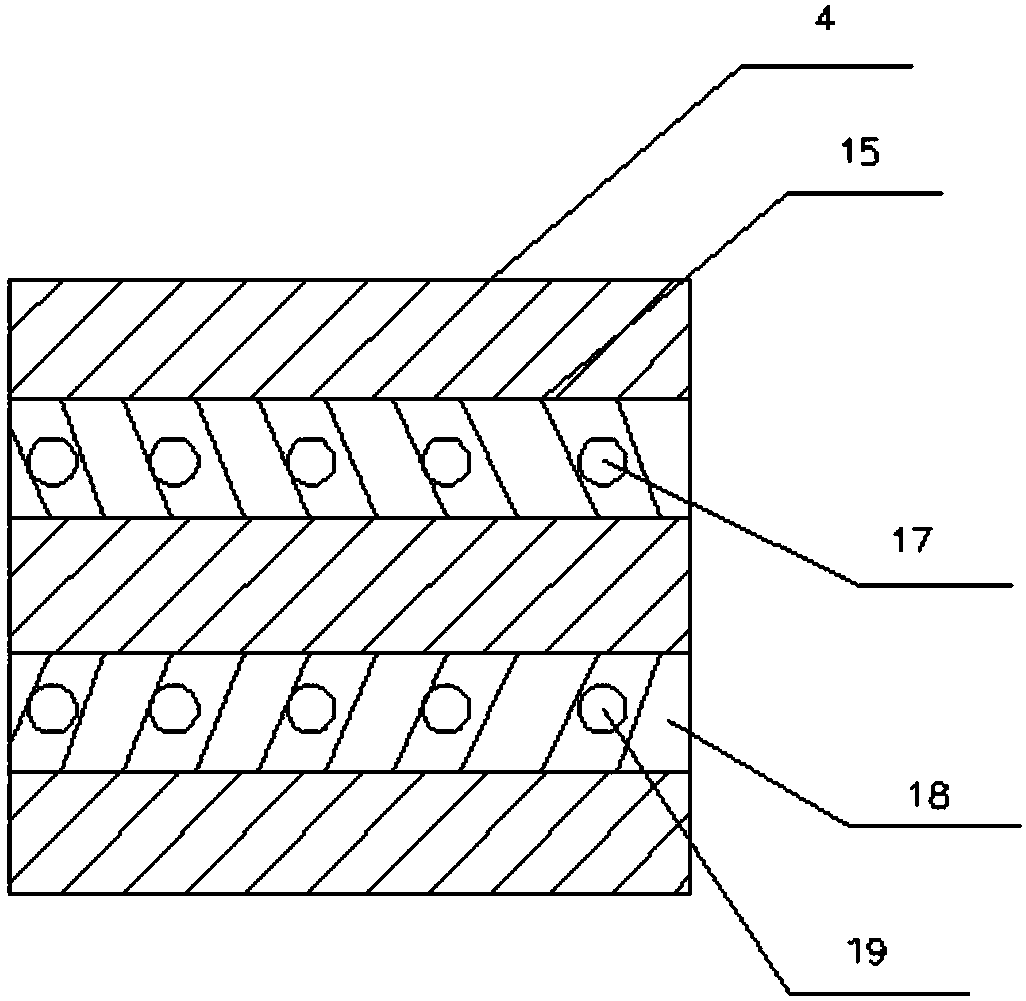

[0027] The rotary machine 1 includes a rotary wheel cylinder 23 and a cylindrical hollow rotary wheel 12. The rotary wheel cylinder 23 buckles the rotary wheel 12 in it. The middle of the cylindrical rotary wheel cylinder 23 is a working chamber, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com