Electric valve driver

A technology of electric valves and drivers, applied in the direction of valve details, valve devices, engine components, etc., can solve the problems of poor meshing efficiency, increased cost, and can only reach about 1 mm, and achieve high precision and smoothness, and stable transmission Reliable, the effect of increasing product life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] The present invention will be further described in detail below in conjunction with the embodiments of the drawings.

[0024] The electric valve driver in this embodiment is in transmission connection with the valve stem of the valve. The electric valve driver can drive the valve to open and close, and can also control the opening of the valve.

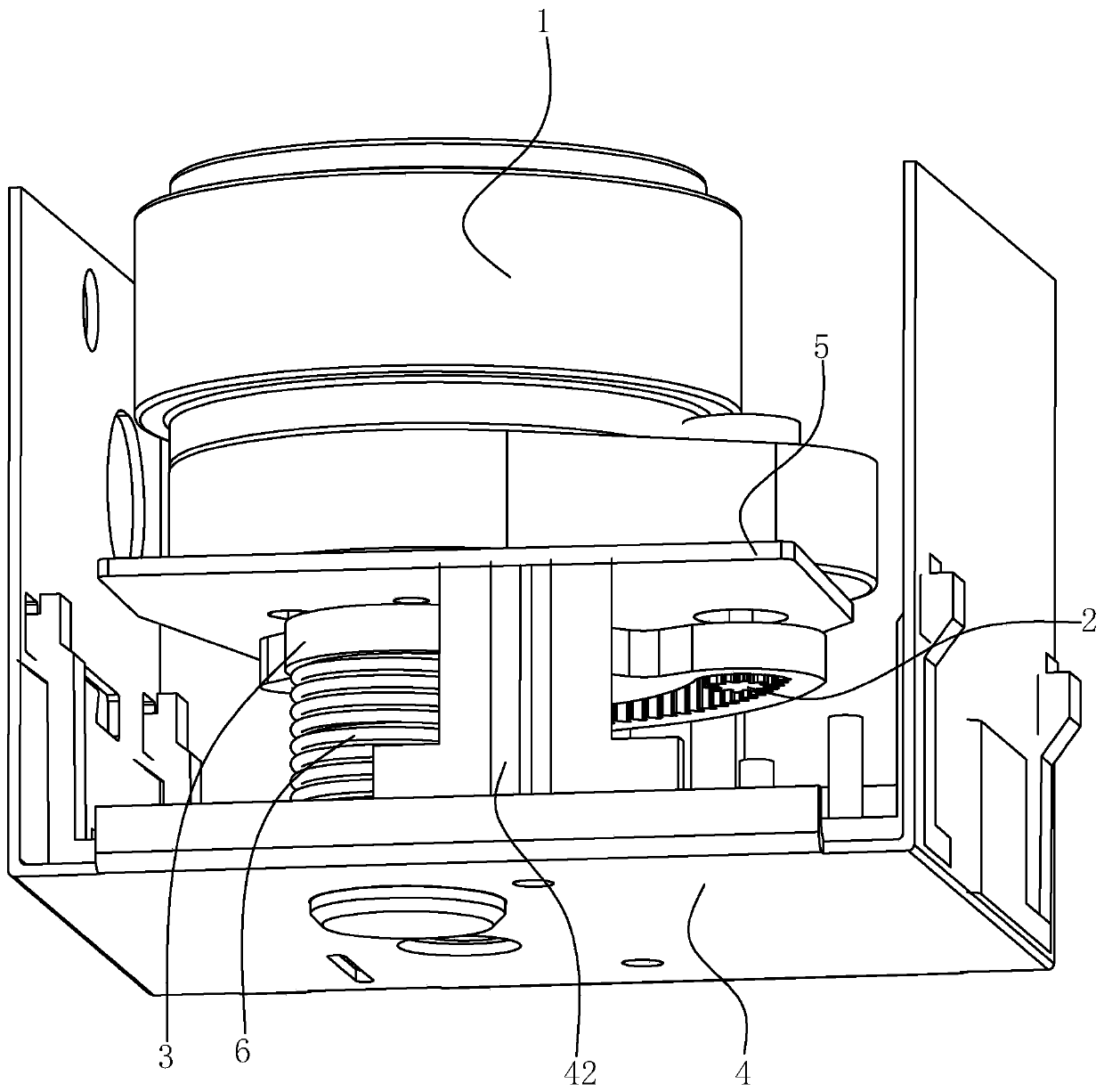

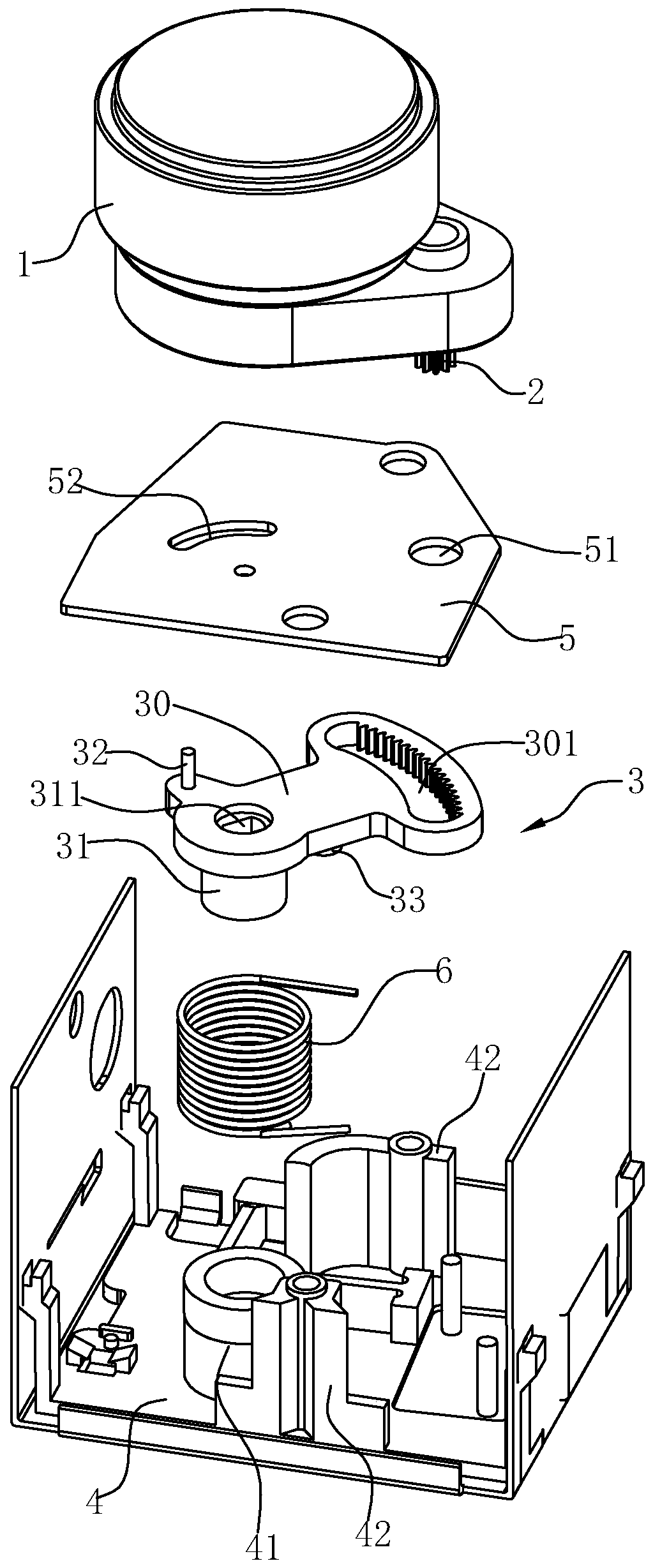

[0025] Such as figure 1 with figure 2 As shown, specifically, the electric valve driver includes a motor 1, a driving gear 2, a transmission gear 3, a base 4, a support plate 5, and a torsion spring 6.

[0026] The drive gear 2 can adopt various drive gears 2 used in the prior art. The drive gear 2 is sleeved and connected to the drive shaft of the motor 1. The outer wall section of the drive gear 2 is circular, and the teeth of the drive gear 2 It is formed on the outer wall surface of the driving gear 2, and the extending length of the tooth portion of the driving gear 2 in the axial direction constitutes the thickness of the toot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap