Multi-sound-path ultrasonic flow measuring pipe section body

A flow measuring tube and multi-sound path technology, which is applied in the direction of measuring flow/mass flow, measuring device, measuring capacity, etc., can solve the problems of high assembly requirements of ultrasonic flow measuring equipment, inability to achieve effective sound path measurement, and high production cost, Achieve the effect of comprehensively capturing flow state distortion, reducing the number of ultrasonic sensors, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

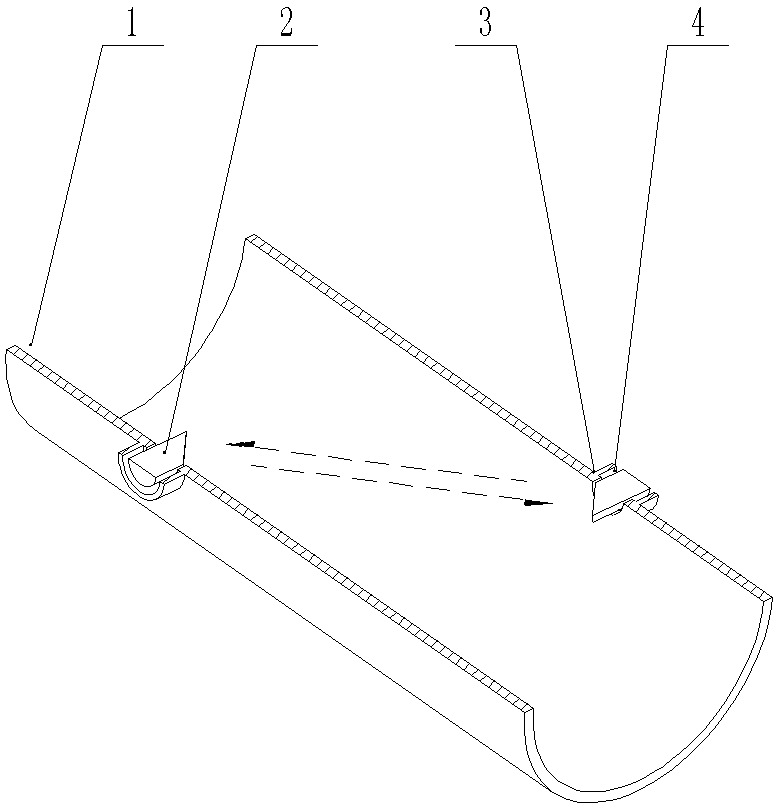

[0038] Embodiment one, with reference to the attached Figure 5 , 12 sound channels, 12 ultrasonic sensors.

[0039] A pipe segment body for multi-sound path ultrasonic flow measurement, comprising a pipe segment body 1, a sensor mounting seat 3, an ultrasonic sensor 2, and a sensor mounting hole 4; the sensor mounting seat has an integrated structure. Multiple sensor mounting seats on the same radial circumference are integrated, the sensor mounting hole of the overall structure is set in the sensor mounting seat, and the ultrasonic sensor is set in the sensor mounting hole; the ultrasonic sensor is divided into upstream and downstream according to the arrangement position on the pipe body. side ultrasonic sensors and downstream side ultrasonic sensors, one upstream side ultrasonic sensor matched with multiple downstream side ultrasonic sensors within its beam width, one downstream side ultrasonic sensor matched with multiple upstream side ultrasonic sensors within its beam w...

Embodiment 2

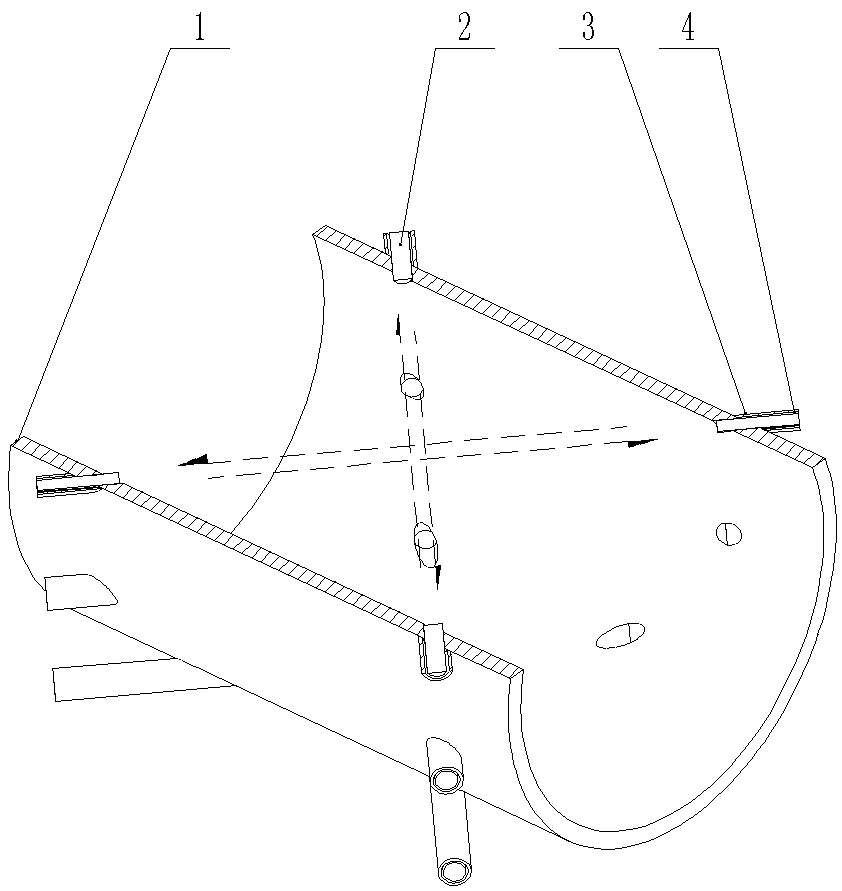

[0040] Embodiment two, referring to the attached Figure 6 , Figure 7 , Figure 8 . 12 sound channels, 12 ultrasonic sensors.

[0041] A pipe segment body for multi-acoustic ultrasonic flow measurement, comprising a pipe segment body 1, a sensor mounting seat 3 and a sensor mounting hole 4; the sensor mounting seat is separate from the pipe segment body. All the sensor mounts are separate units and welded together with the pipe body, the sensor mounting holes are set in the sensor mounts, and the ultrasonic sensors are set in the sensor holes; the ultrasonic sensors are divided into upstream ultrasonic sensors according to their arrangement on the pipe body and downstream side ultrasonic sensors, one upstream side ultrasonic sensor is matched with multiple downstream side ultrasonic sensors within its beam width range, one downstream side ultrasonic sensor is matched with multiple upstream side ultrasonic sensors within its beam width range, 6 upstream side The ultrasonic...

Embodiment 3

[0042] Embodiment three, with reference to the attached Figure 9 . 12 sound channels, 12 ultrasonic sensors.

[0043] A multi-channel ultrasonic flow measurement pipe section body, including a pipe section body 1, a sensor mounting seat 3 and a sensor mounting hole 4; the structure is the same as that of the first or second embodiment.

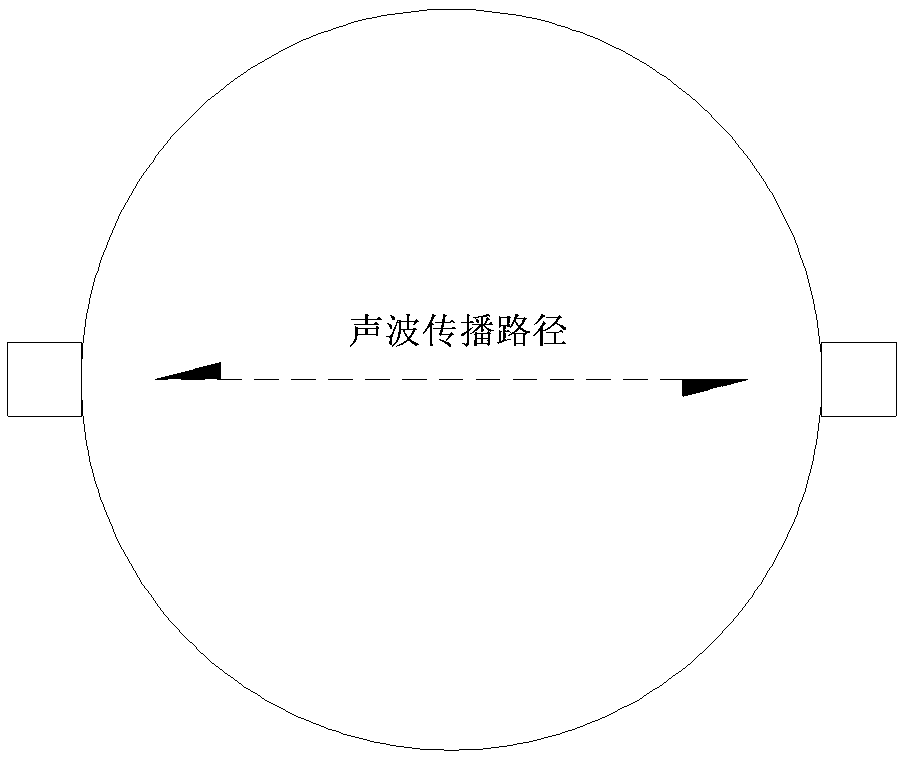

[0044] The number of ultrasonic sensors on the upstream side is equal to the number of ultrasonic sensors on the downstream side. The 6 upstream ultrasonic sensors are arranged on the same section of the pipe body, and the 6 downstream ultrasonic sensors are arranged on the same section of the pipe body; The six ultrasonic sensors are simplified to one point, and the six upstream ultrasonic sensors are sequentially connected along the circumference of the pipe segment with straight lines to form a regular hexagon A; the six downstream ultrasonic sensors are also connected sequentially along the circumference of the pipe segment to form a reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com