Control system of automatic production line for coating process pretreatment and control method thereof

A technology for automatic production lines and painting processes, applied in control/regulation systems, non-electric variable control, surface pretreatment, etc., to solve problems such as errors, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

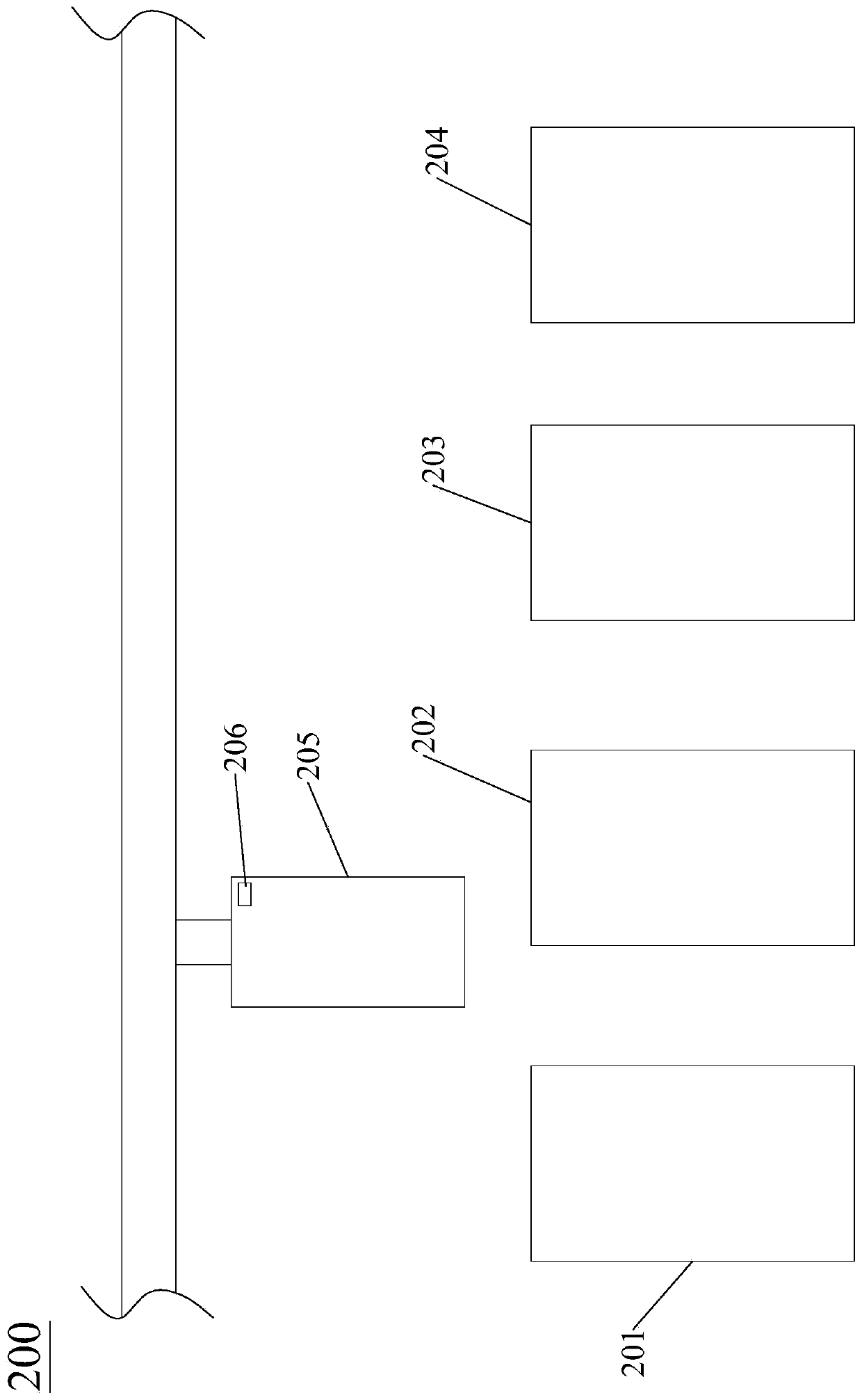

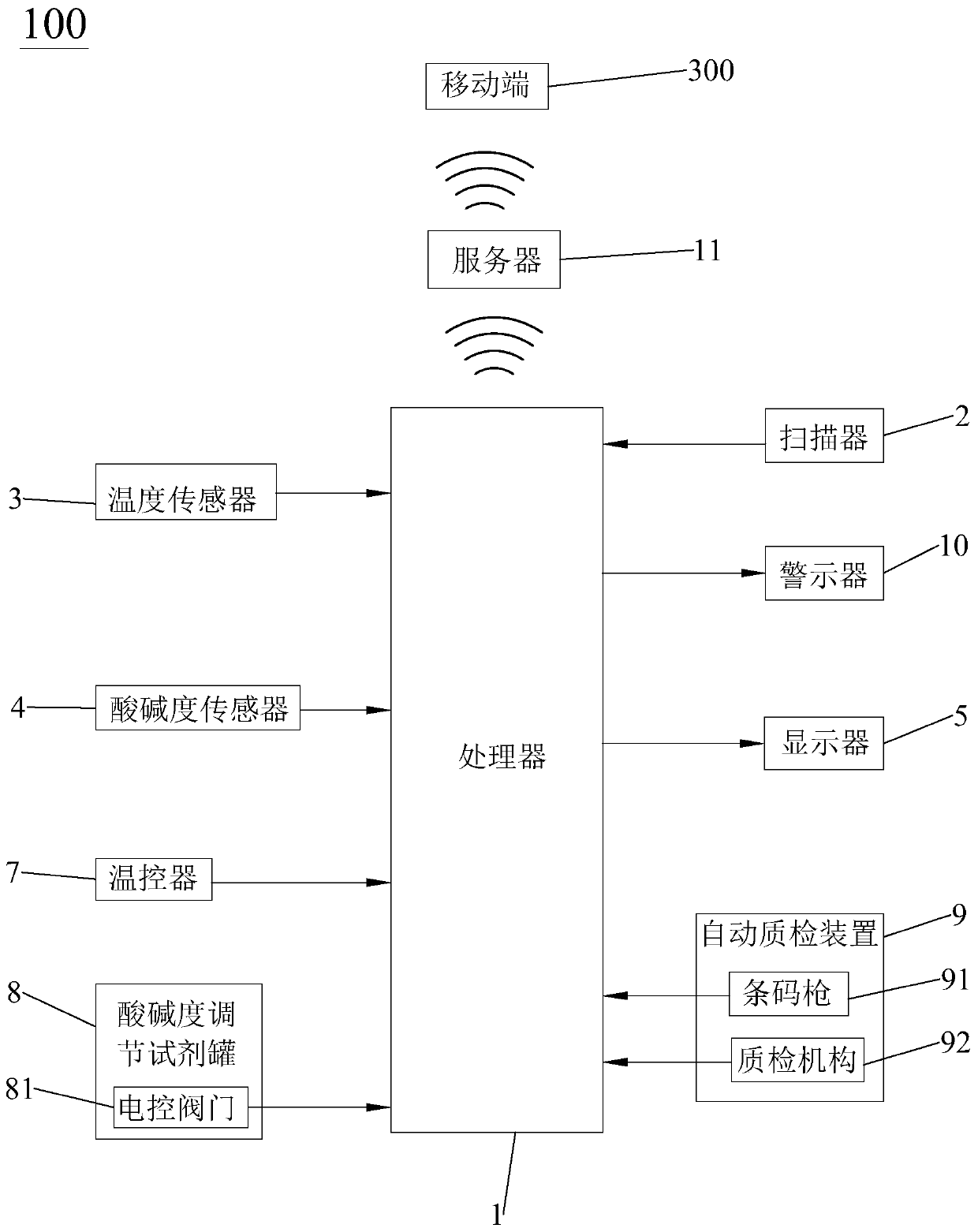

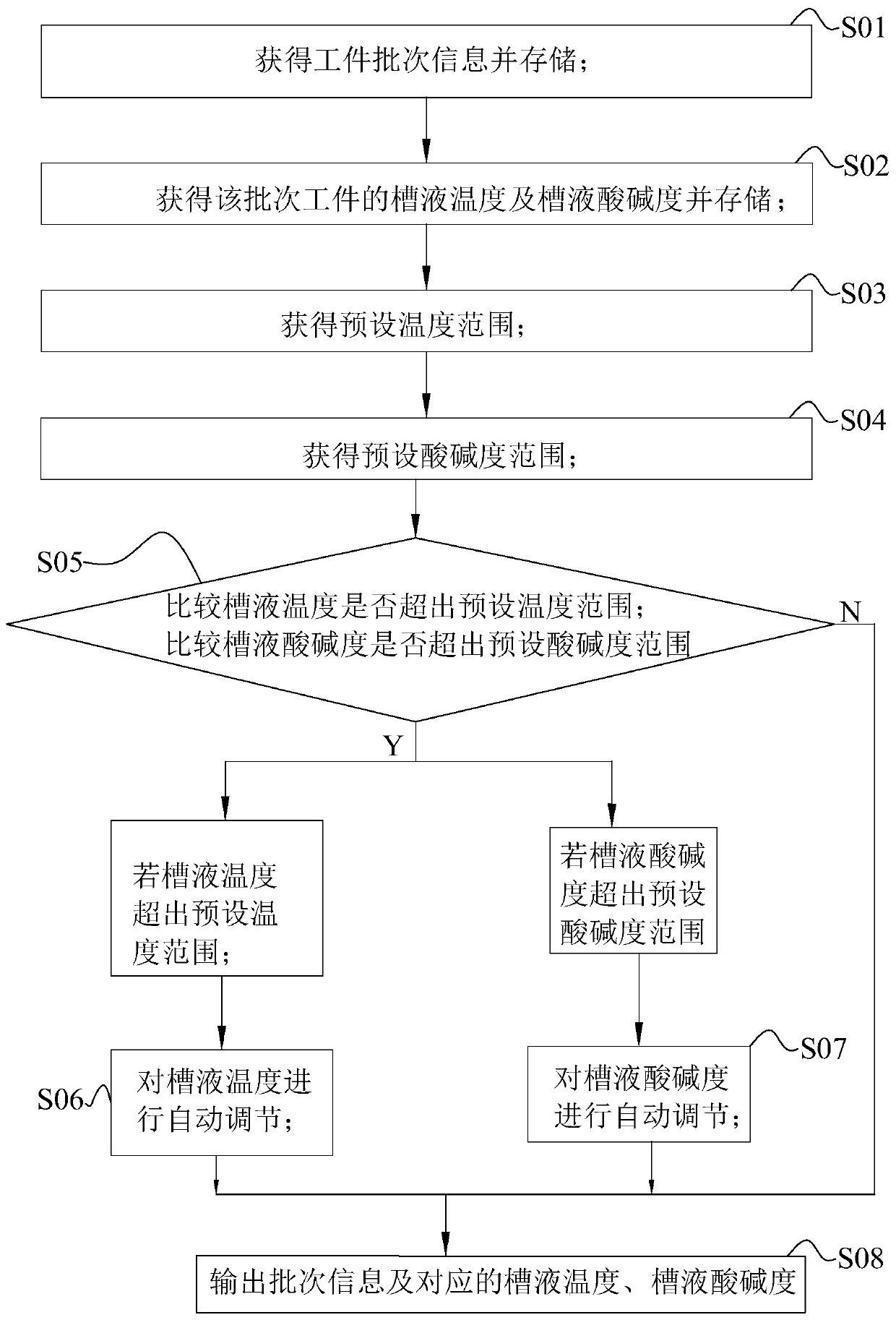

[0044] see figure 1 , the automatic production line 200 for coating process pretreatment includes a hot water washing tank 201, a pre-degreasing tank 202, a main degreasing tank 203, a phosphating tank 204 and successively pass through the water washing tank 201, the pre-degreasing tank 202, the main degreasing tank 203 and the phosphating tank 204 The loading frame 205. It can be understood that the pretreatment method of the coating process includes the following steps: hot water washing - pre-degreasing - main degreasing - two water washings - surface conditioning - phosphating - four water washings. Since the pretreatment method of the coating process is well known to those skilled in the art, it will not be repeated here. The steps of "hot water washing-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com