A kind of preparation method of high-performance iron-based superconducting tape

An iron-based superconducting, high-performance technology, used in superconducting devices, superconducting/high-conducting conductors, metal processing equipment, etc., can solve the problems of difficult to generate texture and small anisotropy, and achieve critical current High density, high texture and good grain connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A kind of preparation method of high-performance iron-based superconducting tape of the present invention, it comprises the following steps:

[0023] Step 1: Making a multi-core precursor wire: mix the 122-phase superconductor powder and dopant, put it into an Ag tube, and process it into a single-core wire by drawing; cut the single-core wire into m sections of the same length, and put The obtained m single-core wires are bundled into a bundle and put into a metal-clad tube, and processed into multi-core wires through cold working methods such as circular die or roller die drawing and rolling, that is, iron-based superconducting multi-core wires are obtained. core precursor wire;

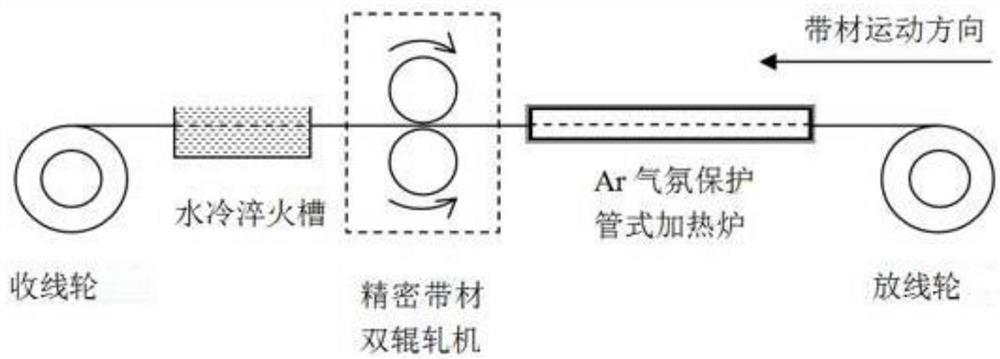

[0024] Step 2: Continuous hot rolling and quenching: the multi-core iron-based superconducting precursor wire obtained in step 1 is used in an online hot-rolling cooling device, and after multiple passes of continuous online hot-rolling and water-cooling quenching, the iron-based superconduc...

Embodiment 1

[0034] Step 1: Making the Multicore Prebody Wire

[0035] 50 g of Ba 0.6 K 0.4 Fe 2 As 2 Phase superconductor powder and 5 g of Sn powder (purity 99.9%) were fully mixed and put into the Ag tube, and the Ag / Ba 0.6 K 0.4 Fe 2 As 2 Drawing and processing into single-core wires; cut the single-core wires into 19 sections of the same length, put 19 single-core wires into a stainless steel tube with an outer diameter of 14 mm and a wall thickness of 1.0 mm, and draw and It was processed into iron-based superconducting multi-core precursor wire with a diameter of 1.0 mm by rolling and other methods.

[0036] Step 2: Continuous hot rolling and quenching

[0037] The iron-based superconducting multi-core precursor wire obtained in step 1 was used figure 1 In the device shown, according to the processing rate of 10% per pass, after multiple passes of continuous on-line hot rolling and water cooling and quenching, the maximum temperature of the strip during the on-line hot rol...

Embodiment 2

[0042] Step 1: Making the Multicore Prebody Wire

[0043] 100 g of Sr 0.6 K 0.4 Fe 2 As 2 Phase superconductor powder and 5 g of Sn powder (purity 99.9%) were fully mixed and put into Ag tube, and the Ag / Sr 0.6 K 0.4 Fe 2 As 2 Drawing and processing into a single-core wire; cut the single-core wire into 37 sections of the same length, put 37 single-core wires into a Ni tube with an outer diameter of 16 mm and a wall thickness of 1.0 mm, and draw and It was processed into iron-based superconducting multi-core precursor wire with a diameter of 2.0 mm by rolling and other methods.

[0044] Step 2: Continuous hot rolling and quenching

[0045] The iron-based superconducting multi-core precursor wire obtained in step 1 was used figure 1 The device shown, according to the processing rate of 50% per pass, after multiple passes of continuous on-line hot rolling and water-cooling quenching, the maximum temperature of the strip during the on-line hot rolling process is 950 ° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com