Shell of oil-immersed transformer

A technology for oil-immersed transformers and casings, applied in transformer/inductor casings, transformer/inductor cooling, etc., can solve the problems of shedding of heat dissipation coating, the upper end is easily heated, and easily corroded, and achieves strong anti-pollution ability, The shell structure is simple and the manufacturing cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

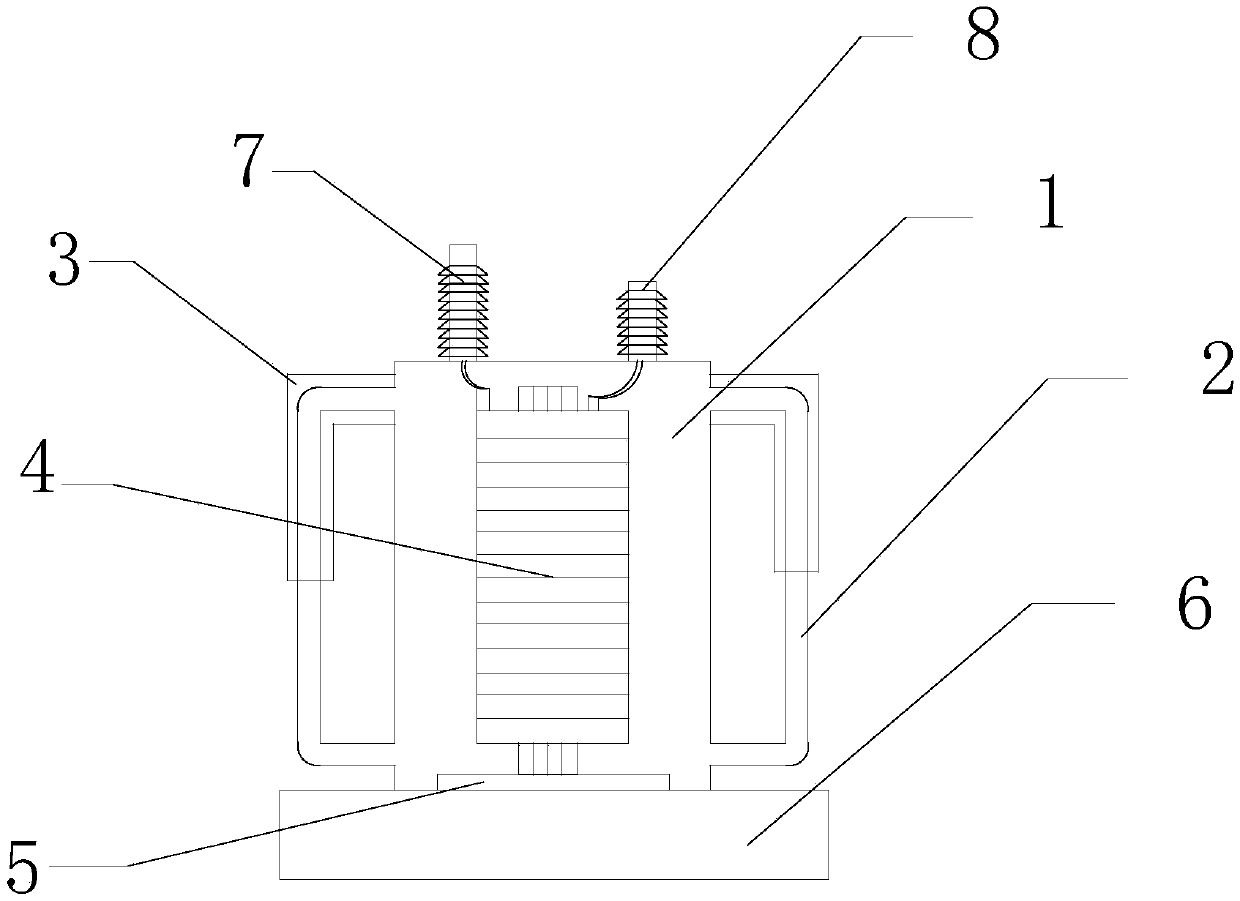

[0021] Such as figure 1 As shown, a shell of an oil-immersed transformer includes an oil tank 1, and heat dissipation pipes 2 are arranged on both sides of the oil tank 1, and a heat dissipation pipe protective shell 3 is installed on the upper surface of the heat dissipation pipe 2, and the heat dissipation pipe protective shell The material of 3 is polytetrafluoroethylene. Since the radiating pipe 2 is the main heat-receiving pipe part in the thermal cycle of the fuel tank 1, especially the upper end of the radiating pipe 2 is the part that receives the most heat. The influence of dust and other dirt will have a great impact on the insulating layer and heat dissipation materials on the surface of the heat dissipation pipe 2. In the worst case, it will cause accidents such as oil leakage, and eventually cause the iron core windings to oxidize when exposed to air, affecting the transformation efficiency. or lead to safety accidents. Therefore, it is particularly important to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap