Metering system of static mixer

A metering system and static mixing technology, used in mixers, fluid mixers, mixer accessories, etc., can solve the problems of inconvenient cleaning, inconvenience in fast delivery of materials, inability to guarantee weighing accuracy, etc., to improve work efficiency and ensure The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

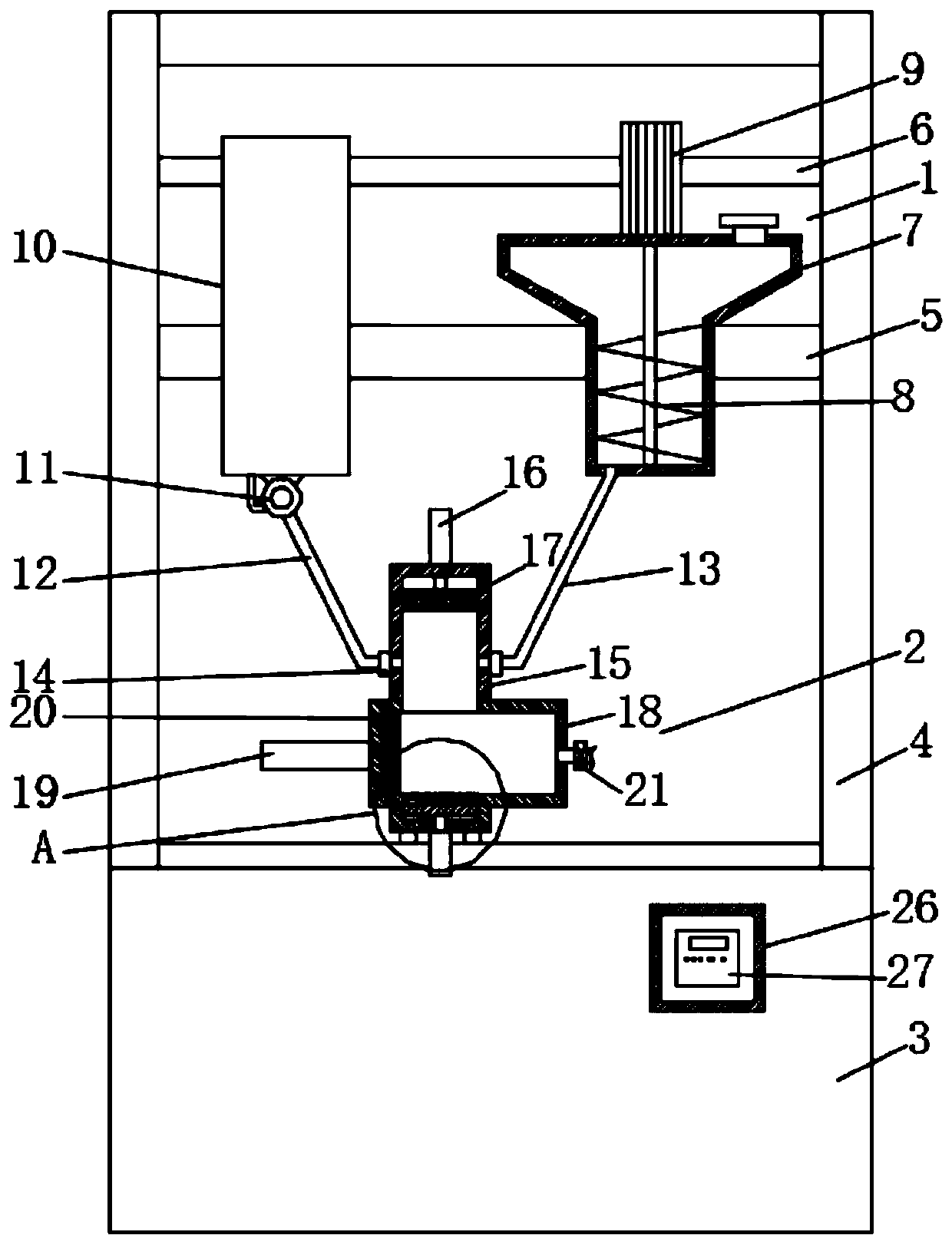

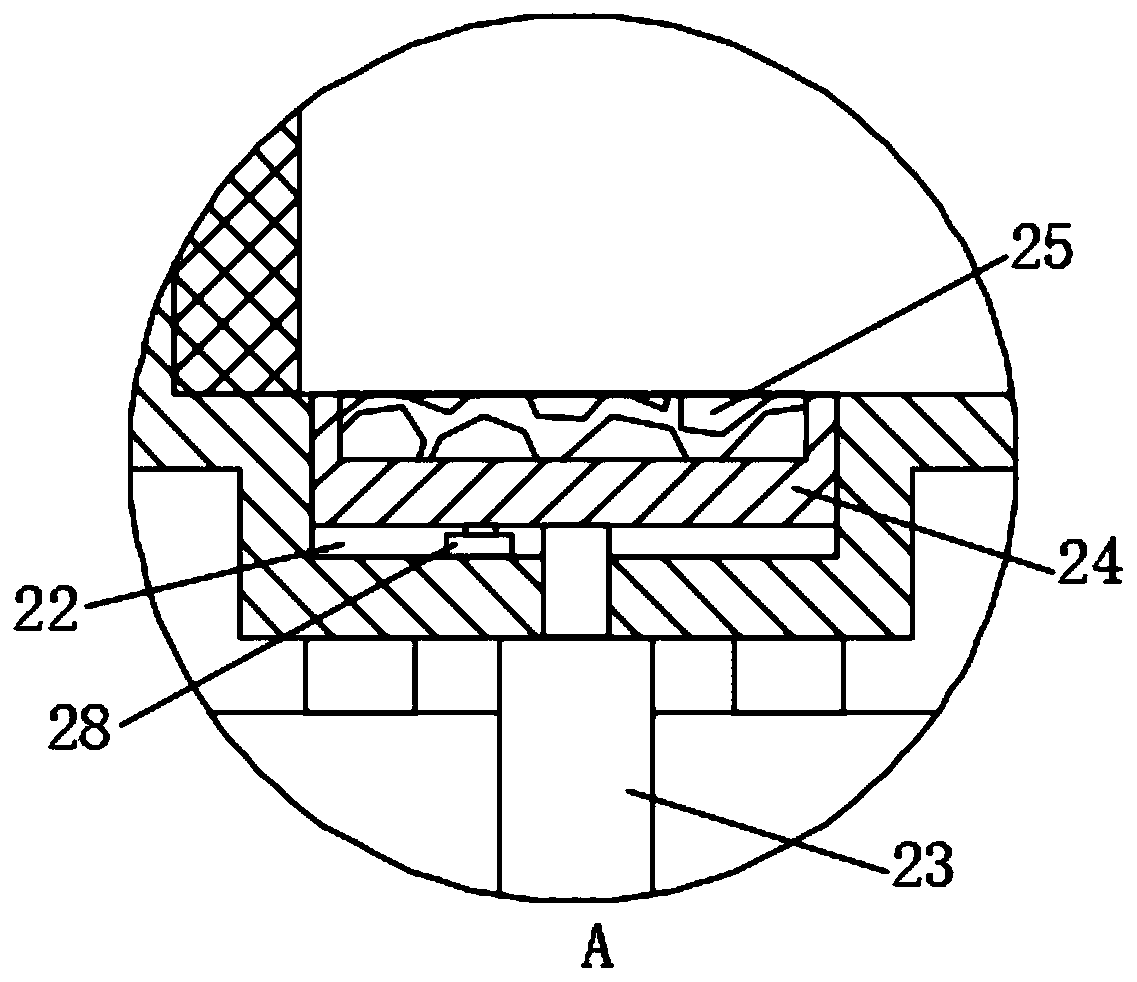

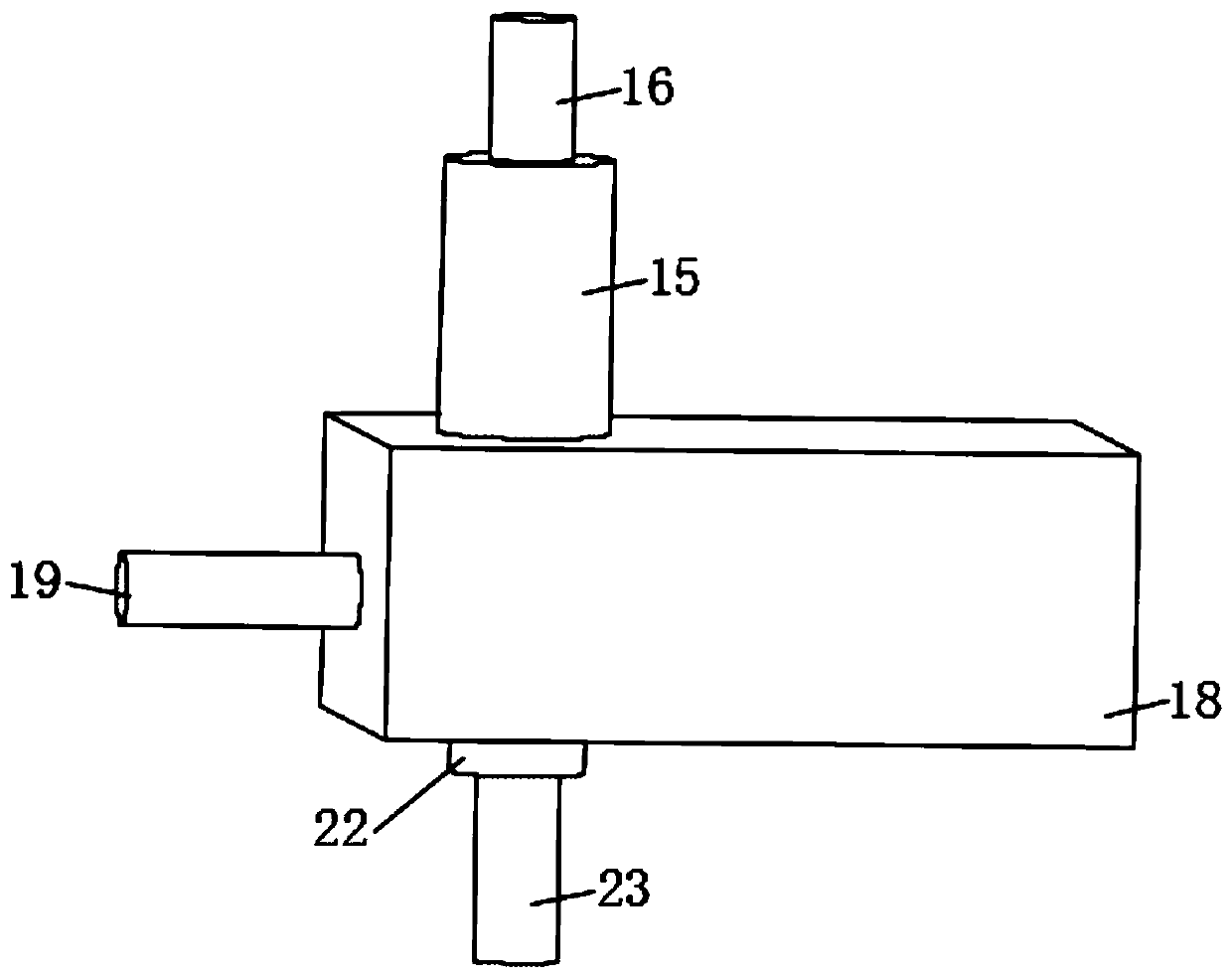

[0020] Such as Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: a metering system of a static mixer, including a feeding mechanism 1, a metering mechanism 2 and a workbench 3, and the top of the workbench 3 is fixedly equipped with a metering mechanism 2, so The top of the metering mechanism 2 is provided with a feeding mechanism 1, and the feeding mechanism 1 is composed of a fixed side plate 4, a first fixing frame 5, a second fixing frame 6, a first storage pipe 7, a feeding screw 8, a lower Material motor 9, second material storage pipe 10, gear pump 11, liquid delivery pipe 12, material delivery hose 13 and first electromagnetic valve 14, both sides of the top of the workbench 3 are fixedly installed with fixed side plates 4 A first fixed frame 5 is fixedly installed between the fixed side plates 4, a second fixed frame 6 is fixedly installed between the fixed side plates 4 and above the first fixed frame 5, and the first fixed fram...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap