Sorgho stalk section head subsection cutting equipment

A technology of joint head and sweet rod, applied in the direction of metal processing, etc., can solve the problems of different cutting length, easy to be cut by sickle, and more labor consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

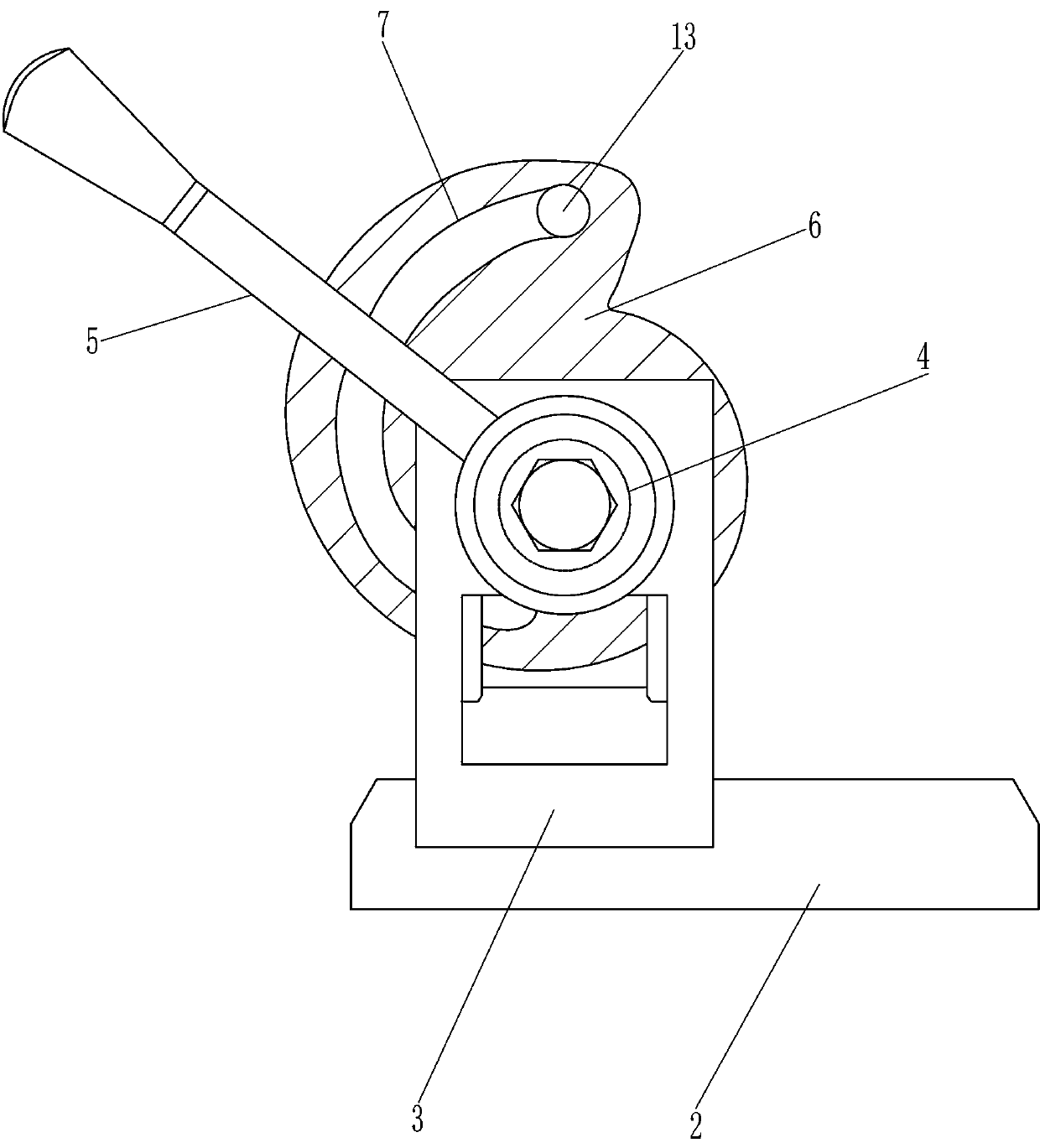

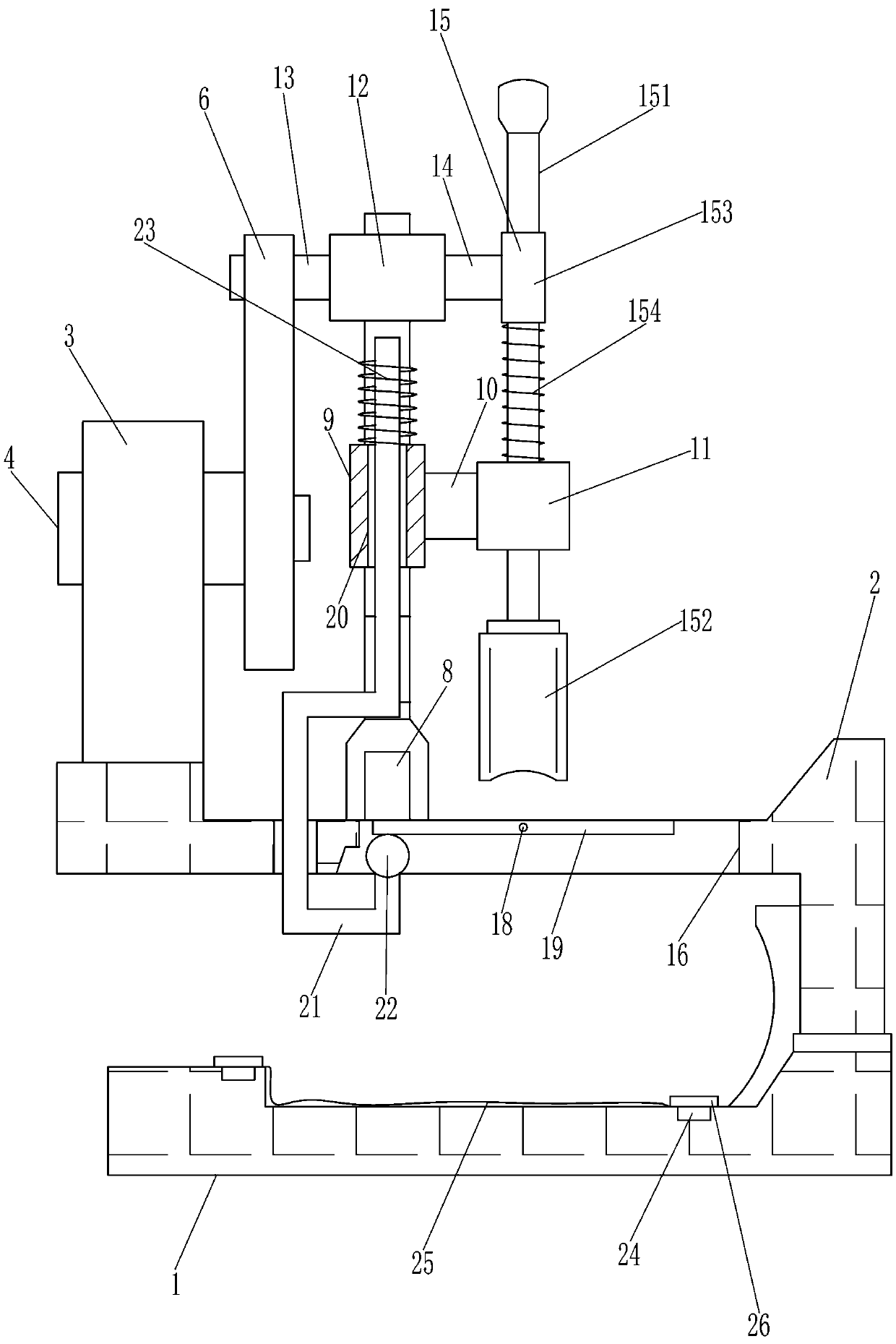

[0017] A kind of sweet bar section head section excision equipment, such as Figure 1-3 As shown, it includes a base 1, a mounting seat 2, a mounting frame 3, a first rotating shaft 4, a rotating rod 5, a cam disc 6, an L-shaped sliding rod 8, a fixed sleeve 9, a first support rod 10, a guide sleeve 11, a sliding Cover 12, the first push rod 13, the second push rod 14 and the cutting device 15, the top right side of the base 1 is provided with the mounting seat 2, the base 1 is connected with the mounting seat 2 by welding, and the left side of the mounting seat 2 is provided Mounting frame 3 is arranged, and the middle rotating type of mounting frame 3 tops is provided with first rotating shaft 4, and the left part of first rotating shaft 4 is provided with rotating rod 5, and the right part of first rotating shaft 4 is provided with cam disc 6, and arc is arranged on cam disc 6. Shaped groove 7, the left side of the top of the mounting base 2 is provided with an L-shaped sli...

Embodiment 2

[0019] A kind of sweet bar section head section excision equipment, such as Figure 1-3 As shown, it includes a base 1, a mounting seat 2, a mounting frame 3, a first rotating shaft 4, a rotating rod 5, a cam disc 6, an L-shaped sliding rod 8, a fixed sleeve 9, a first support rod 10, a guide sleeve 11, a sliding Cover 12, the first push rod 13, the second push rod 14 and the cutting device 15, the right side of the base 1 top is provided with the mounting seat 2, the left side of the mounting seat 2 top is provided with the mounting frame 3, and the middle rotating type of the mounting frame 3 top is provided. There is a first rotating shaft 4, the left part of the first rotating shaft 4 is provided with a rotating rod 5, the right part of the first rotating shaft 4 is provided with a cam disc 6, an arc-shaped groove 7 is opened on the cam disc 6, and a L Type slide bar 8, L-type slide bar 8 is positioned at the right side of mounting frame 3, L-shaped slide bar 8 middle part...

Embodiment 3

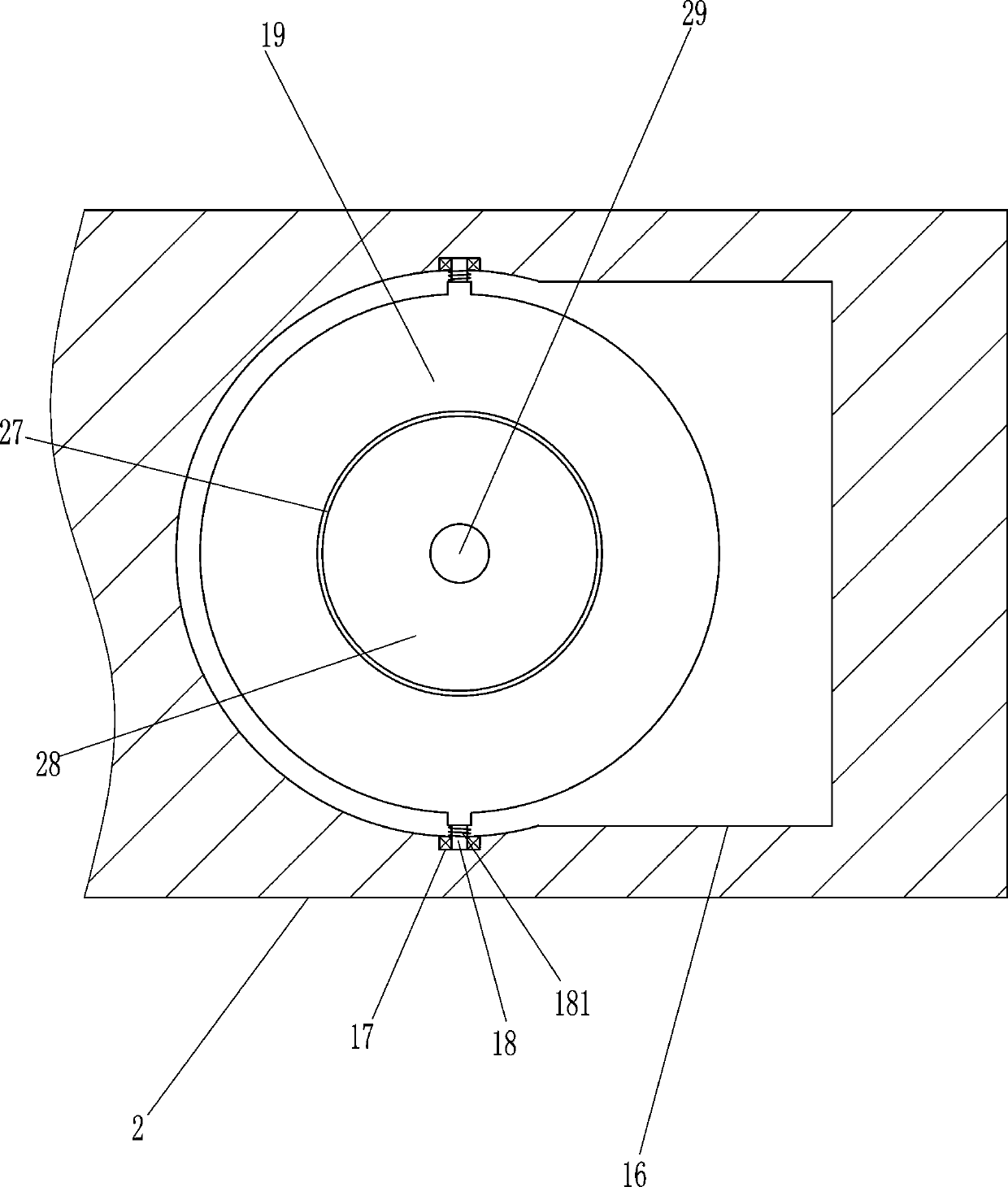

[0022] A kind of sweet bar section head section excision equipment, such as Figure 1-4 As shown, it includes a base 1, a mounting seat 2, a mounting frame 3, a first rotating shaft 4, a rotating rod 5, a cam disc 6, an L-shaped sliding rod 8, a fixed sleeve 9, a first support rod 10, a guide sleeve 11, a sliding Cover 12, the first push rod 13, the second push rod 14 and the cutting device 15, the right side of the base 1 top is provided with the mounting seat 2, the left side of the mounting seat 2 top is provided with the mounting frame 3, and the middle rotating type of the mounting frame 3 top is provided. There is a first rotating shaft 4, the left part of the first rotating shaft 4 is provided with a rotating rod 5, the right part of the first rotating shaft 4 is provided with a cam disc 6, an arc-shaped groove 7 is opened on the cam disc 6, and a L Type slide bar 8, L-type slide bar 8 is positioned at the right side of mounting frame 3, L-shaped slide bar 8 middle part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com