Blow-molding method for sun shield sheet machine

A blow molding and sheet machine technology, applied in the field of blow molding, can solve the problems of increasing the molding cycle of plastic parts and wasting time, and achieve the effects of shortening the molding cycle, saving material and manpower, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

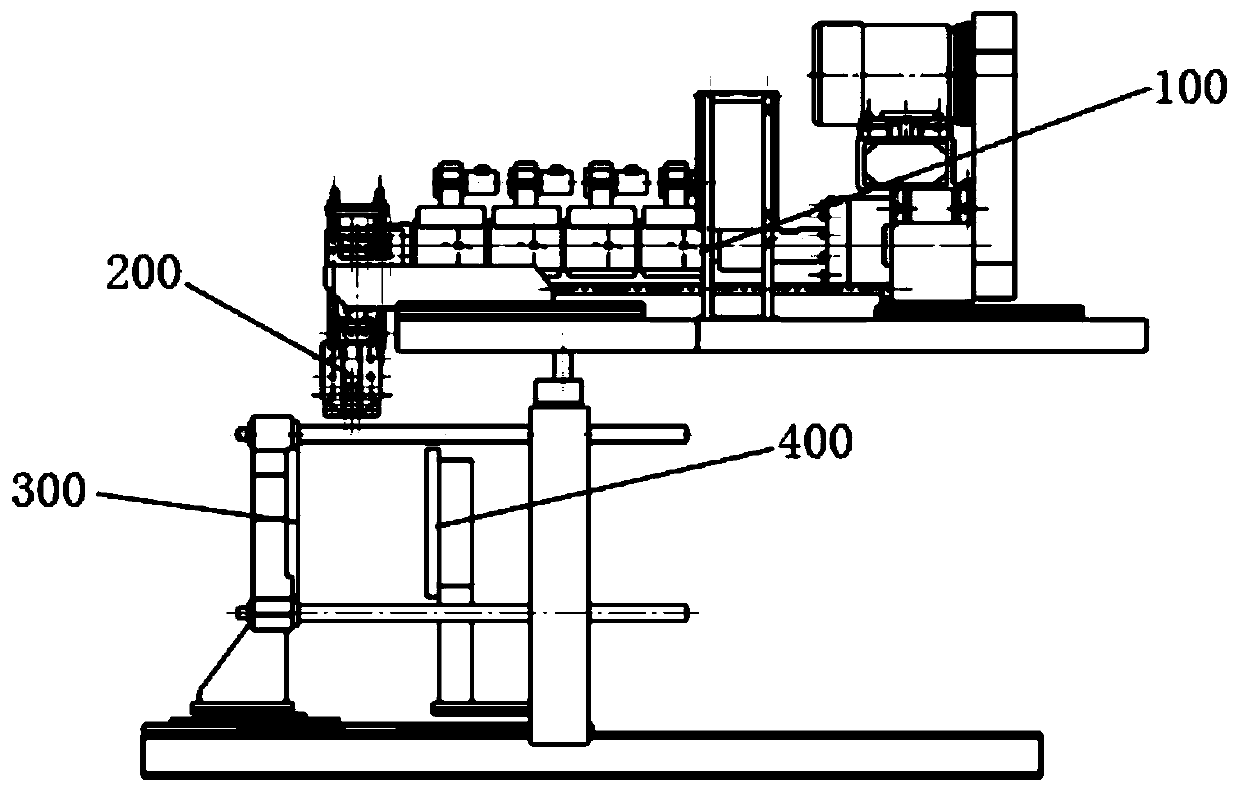

[0025] see Figure 1~3 , in an embodiment of the present invention, a sun visor sheet machine blow molding method, comprising the following steps:

[0026] S1, the plastic (polyethylene) is melted and plasticized through the extruder 100, and the screw of the extruder 100 drives the melted plastic to move to the head position of the extruder 100;

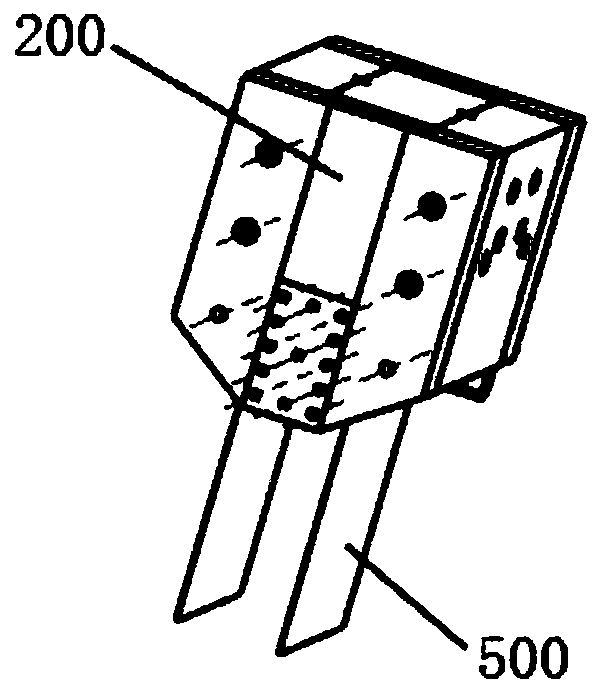

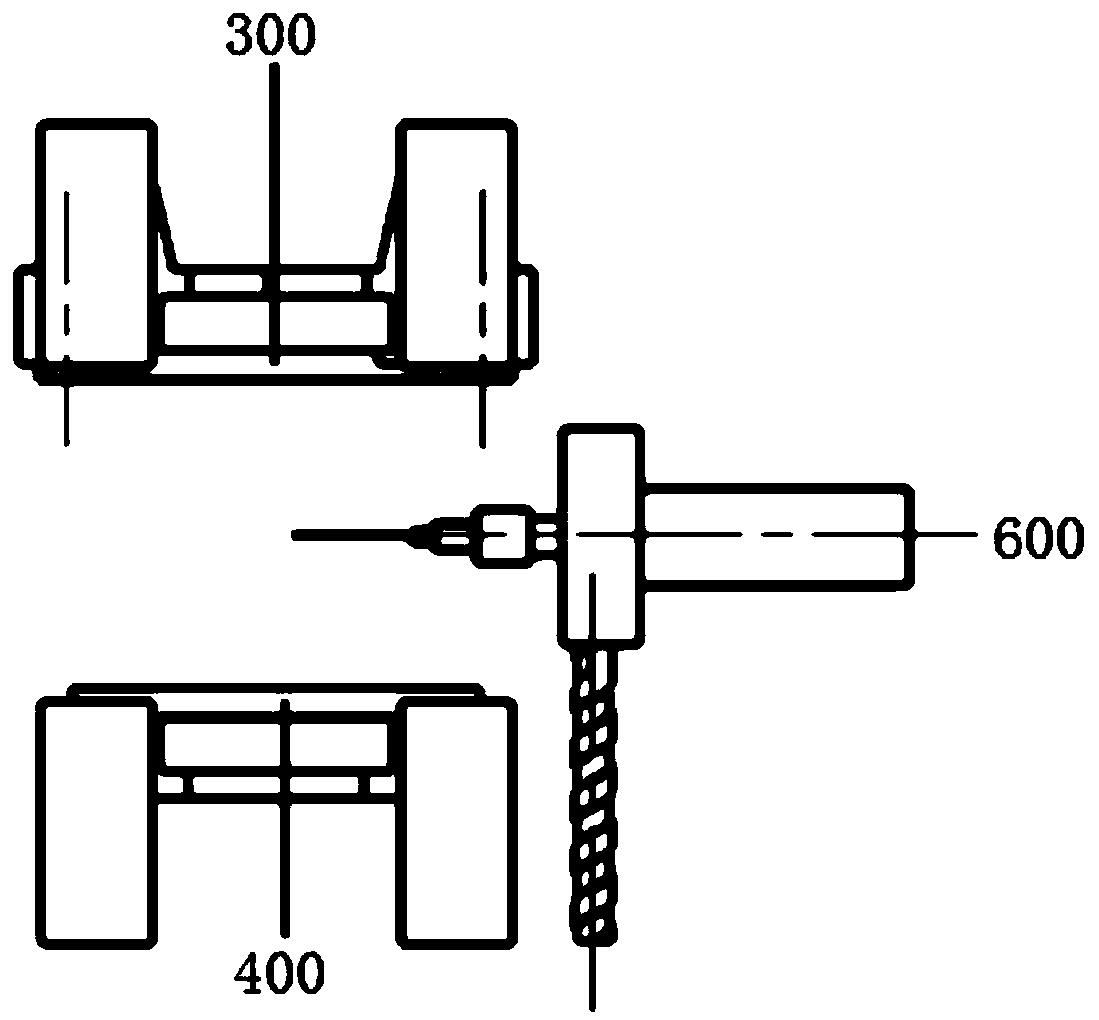

[0027] S2, the head of the extruder extrudes two sheets of parison 500 through the die 200 into the mold (composed of the left mold 300 and the right mold 400), and after the parison 500 is in place, fix the insert 600 on the mold In the appropriate position within the mold, start mold closing, and the mold closing time is 0.7 to 0.8 seconds; Air blowing, the pre-blowing air pressure is 0.7-0.8MPa, the pre-blowing time is 8-12 seconds, and the mold clamping starts after the pre-blowing is completed;

[0028] S3, after the mold clamping is in place, the sheet-shaped parison 500 is wrapped on the outside of the insert 600, and the t...

Embodiment 2

[0032] see Figure 1~3 , in an embodiment of the present invention, a sun visor sheet machine blow molding method, comprising the following steps:

[0033] S1, the plastic (polyethylene) is melted and plasticized by the extruder 100, and the screw of the extruder 100 drives the molten plastic to move to the position of the head of the extruder 100. Here, the material of the extruder 100 The barrel has several heating sections. In this embodiment, the number of heating sections is two. Along the discharge direction of the extruder, the heating temperature of the first heating section is 165°C to 170°C, and the heating temperature of the second heating section is The heating temperature of the section is 175°C to 180°C, which can avoid defects such as poor plasticization of polyethylene, poor parison expansion and stretching, and poor surface gloss of the product caused by low extrusion temperature;

[0034] In addition, in order to monitor the temperature, several temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com