Automobile exhaust pipe hot embedment device

A technology for automobile exhaust and exhaust pipes, which is applied in the field of thermal embedding devices for automobile exhaust pipes, which can solve problems such as thermal embedding of exhaust pipes, and achieve the effects of high heating efficiency, improved stability, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

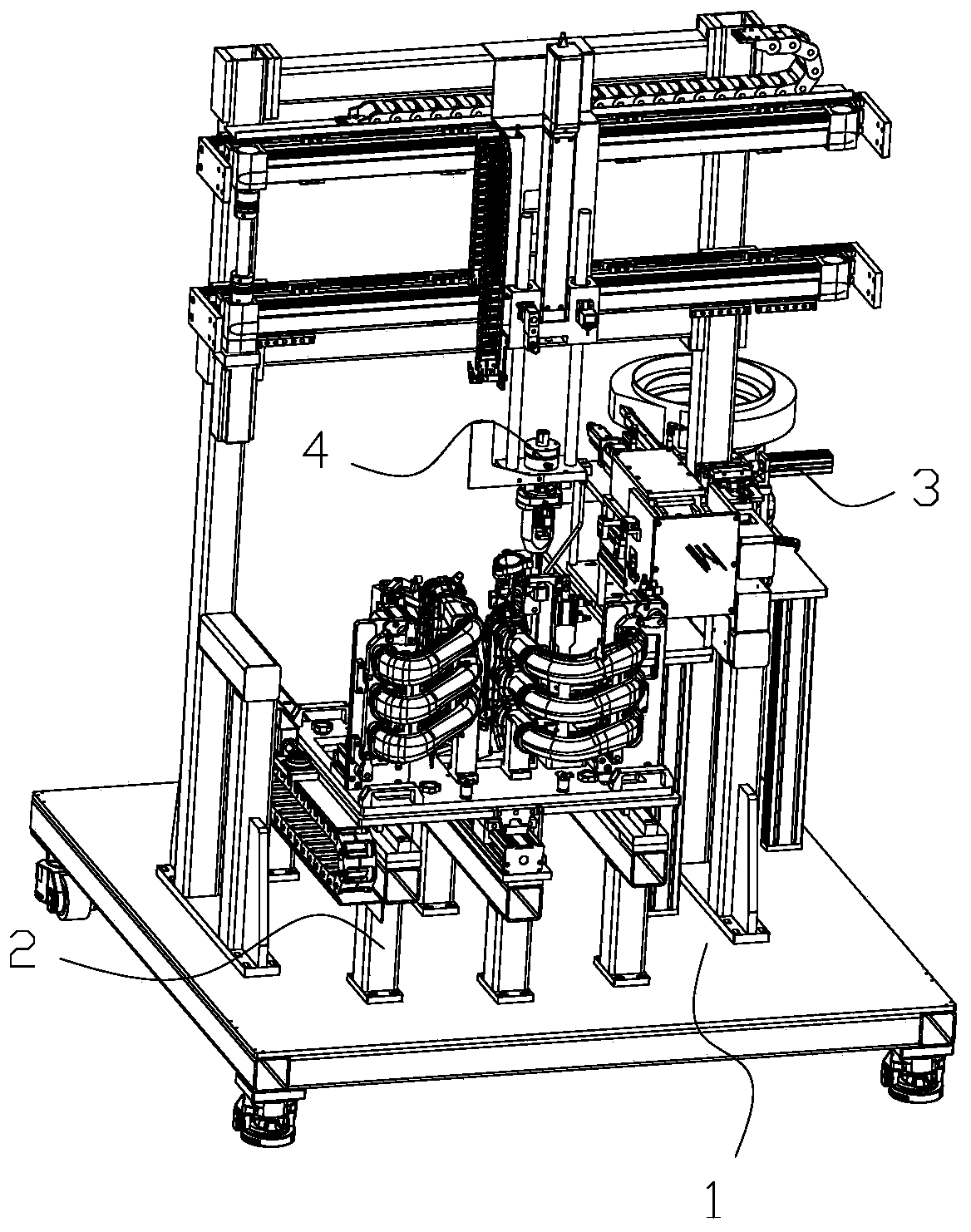

[0022] Such as figure 1 As shown, a heat embedding device for an automobile exhaust pipe, the device includes a heat embedding base 1, a heat embedding fixture module 2, a heat embedding feeding module 3 and a heat embedding processing module 4; the heat embedding fixture module 2 is arranged on the heat embedding base 1 In the middle part, the hot-fitting fixture module 2 is used to limit and fix the exhaust pipe; the hot-fitting feeding module 3 is arranged at the right rear part of the hot-fitting base 1, and the hot-fitting feeding module 3 is used to automatically feed the nuts and Heating; the thermal embedding processing module 4 is arranged on the thermal embedding base 1 and located above the thermal embedding fixture module 2 , and the thermal embedding processing module 4 is used for thermally embedding the nut onto the exhaust pipe.

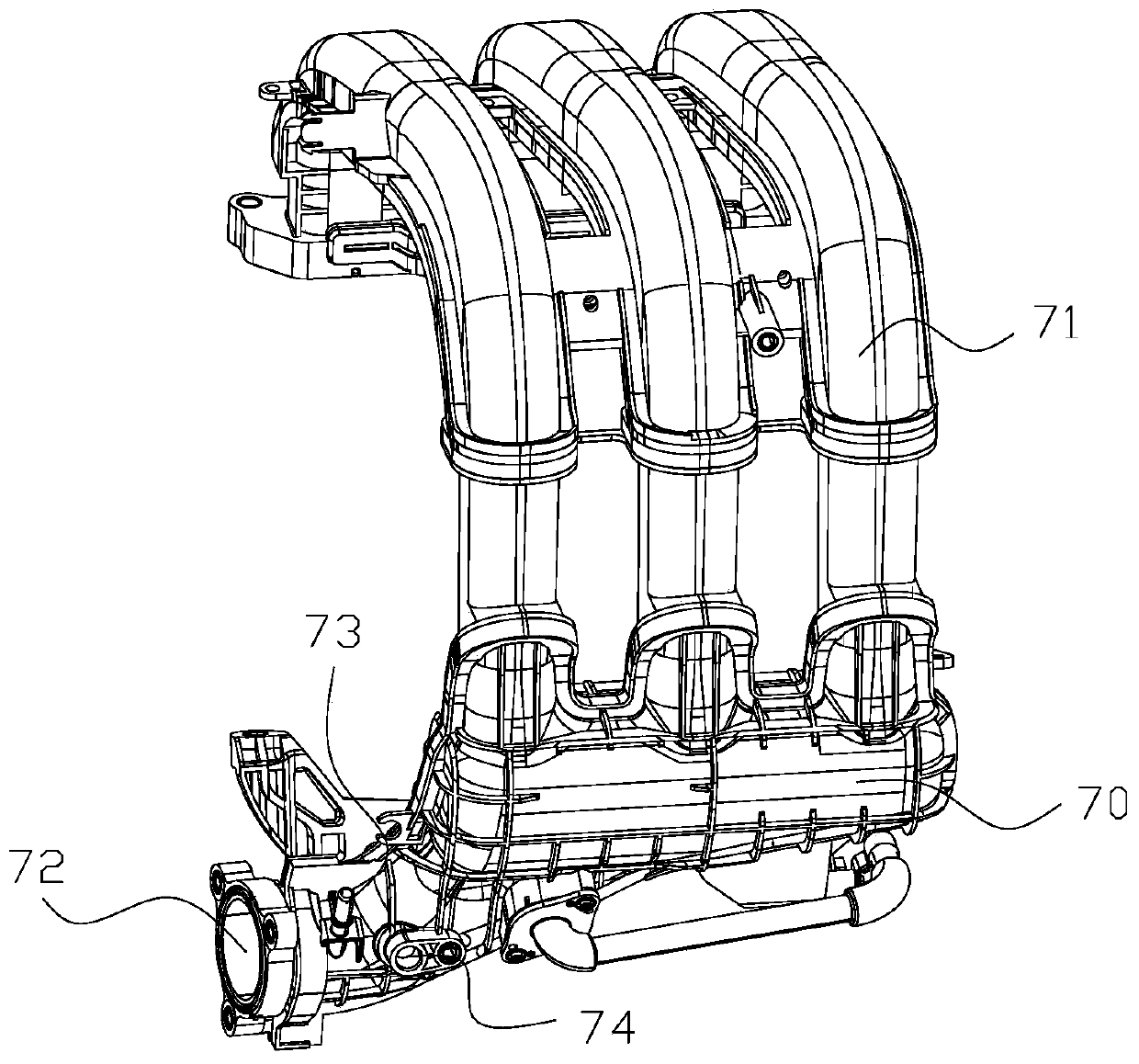

[0023] Such as figure 2 As shown in the figure, the exhaust pipe that needs to be detected is shown in the figure. The exhaust pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com