Novel operation rack for tunnel construction and use method thereof

A technology for tunnel construction and workbench, which can be used in tunnels, tunnel lining, earthwork drilling, etc., and can solve problems such as high failure rate and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

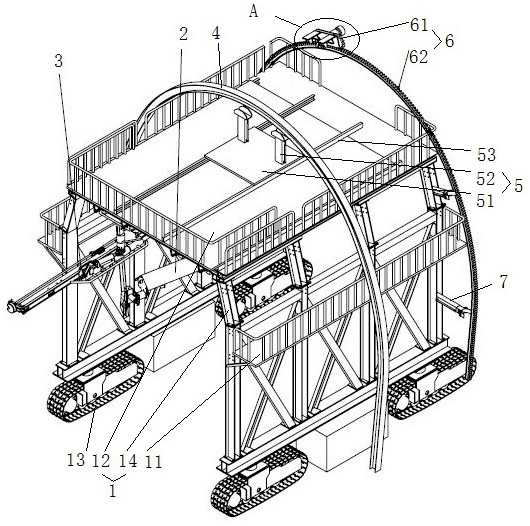

[0051] Embodiment 1: as Figure 1~Figure 7 As shown, a new workbench for tunnel construction according to the present invention includes a movable gantry 1, and the moveable gantry device is the main load-bearing part of the workbench. The mobile gantry 1 includes a door frame 11, and the door frame 11 includes pillar supports on both sides, beam supports on the top, and a roof laid on the beam supports, and a channel is formed at the bottom of the door frame 11, which can pass through the cantilever roadheader; The working platform saves the construction space, not only facilitates the passage of construction personnel and other equipment, but also facilitates the transportation of construction materials; the mobile gantry 1 is equipped with a concrete spraying device 2, a bolter device 3 and a steel arch assembly device , the concrete spraying device 2 is used to spray concrete to the tunnel wall for preliminary support, the bolter device 3 is used for bolt support, and the ...

Embodiment 2

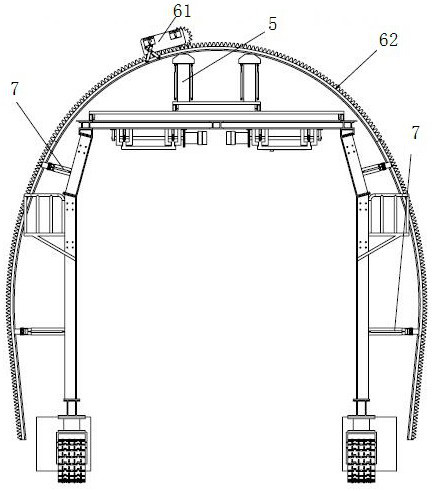

[0053] Embodiment 2: as figure 1 and figure 2 As shown, the moving mechanism 6 includes a moving track 61 and a walking assembly 62. The walking assembly 62 is connected to the moving track 61 and can move and walk on the moving track 61. The arc of the moving track 61 matches the arch of the steel arch , the moving track 61 provides the walking assembly 62 with a track for moving the steel arch to the corresponding position of the arch structure; the walking assembly 62 is provided with a holding member 625 for clamping the steel arch for clamping and fixing the steel arch , so that the steel arch moves following the movement of the walking assembly 62 .

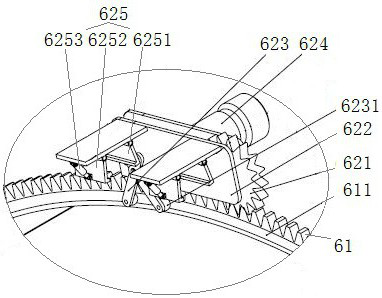

[0054] Further, as image 3 As shown, the moving track 61 is an arched large ring gear, and the walking assembly 62 includes a support frame 622 and a pinion 621 rotatably connected to the support frame 622, and the pinion gear 621 is meshed with the large ring gear; The frame 622 is provided with a drive motor 624 that...

Embodiment 3

[0056] Embodiment 3: as image 3 As shown, the holding member 625 includes a fixed arm 6251 and a movable arm 6252 relatively arranged on the support frame 622. The fixed arm 6251 and the movable arm 6252 are symmetrical L-shaped structures, which are convenient for clamping and fixing the steel arch. Frame; the movable arm 6252 is hinged with the support frame 622, and the support frame 622 is provided with an opening and closing driver 6253 that drives the movable arm 6252 to open and close. In this embodiment, the opening and closing driver 6253 is a push cylinder, and the push cylinder The fixed end is hinged with the support frame 622, and the telescopic end is hinged with the movable arm 6252, which is used to control the movable arm 6252 to rotate close to the fixed arm 6251 to close or to rotate away from the fixed arm 6251 to open. When working, the walking assembly 62 is located at the lower part of the mobile door frame 1, which is convenient to clamp and fix the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com