Self-adaptive steel structure connecting joint and connecting method thereof

A structural connection and self-adaptive technology, applied in the direction of building structure, construction, instruments, etc., can solve the problems of affecting the connection strength of the welding surface, loosening of the pressure bearing time, and the transfer of unfavorable stress, so as to facilitate abnormal detection and convenient connection and separation, to facilitate the effect of stress transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

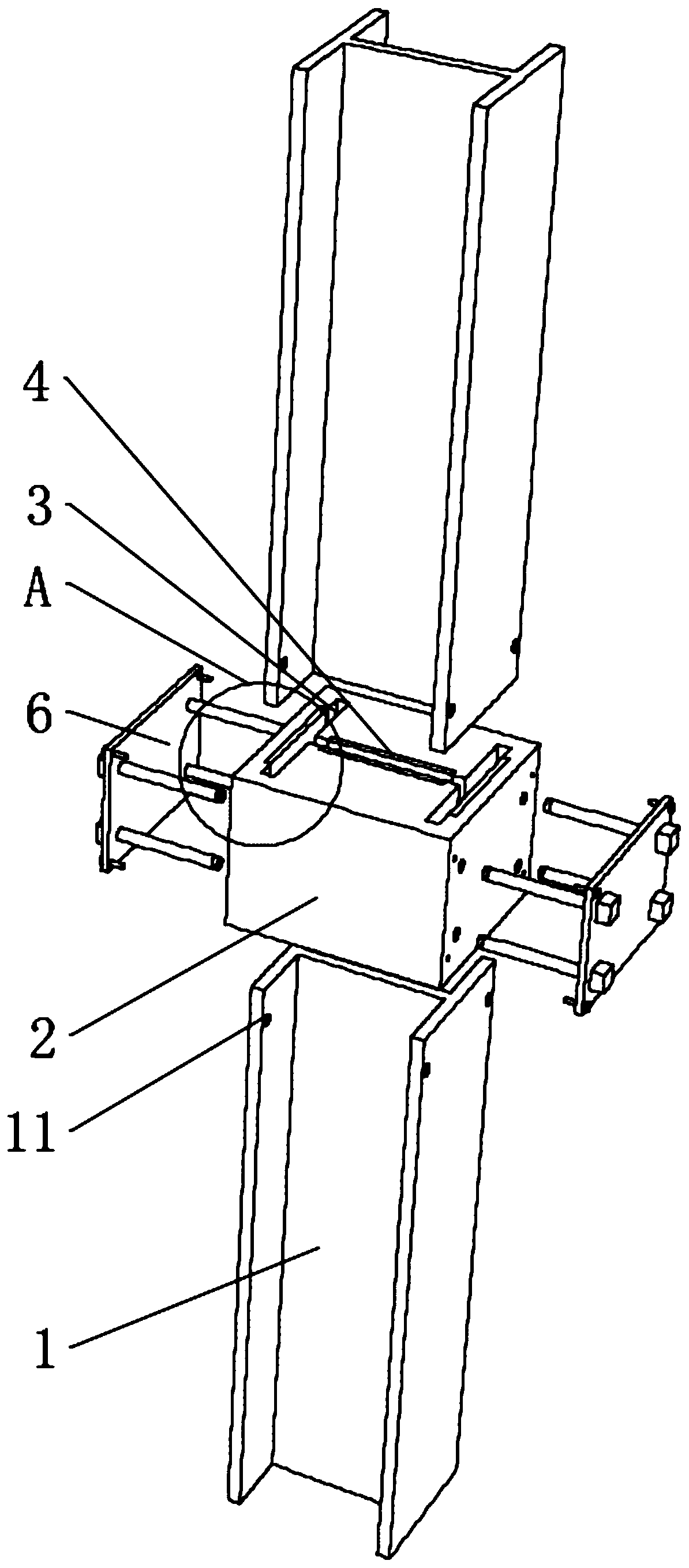

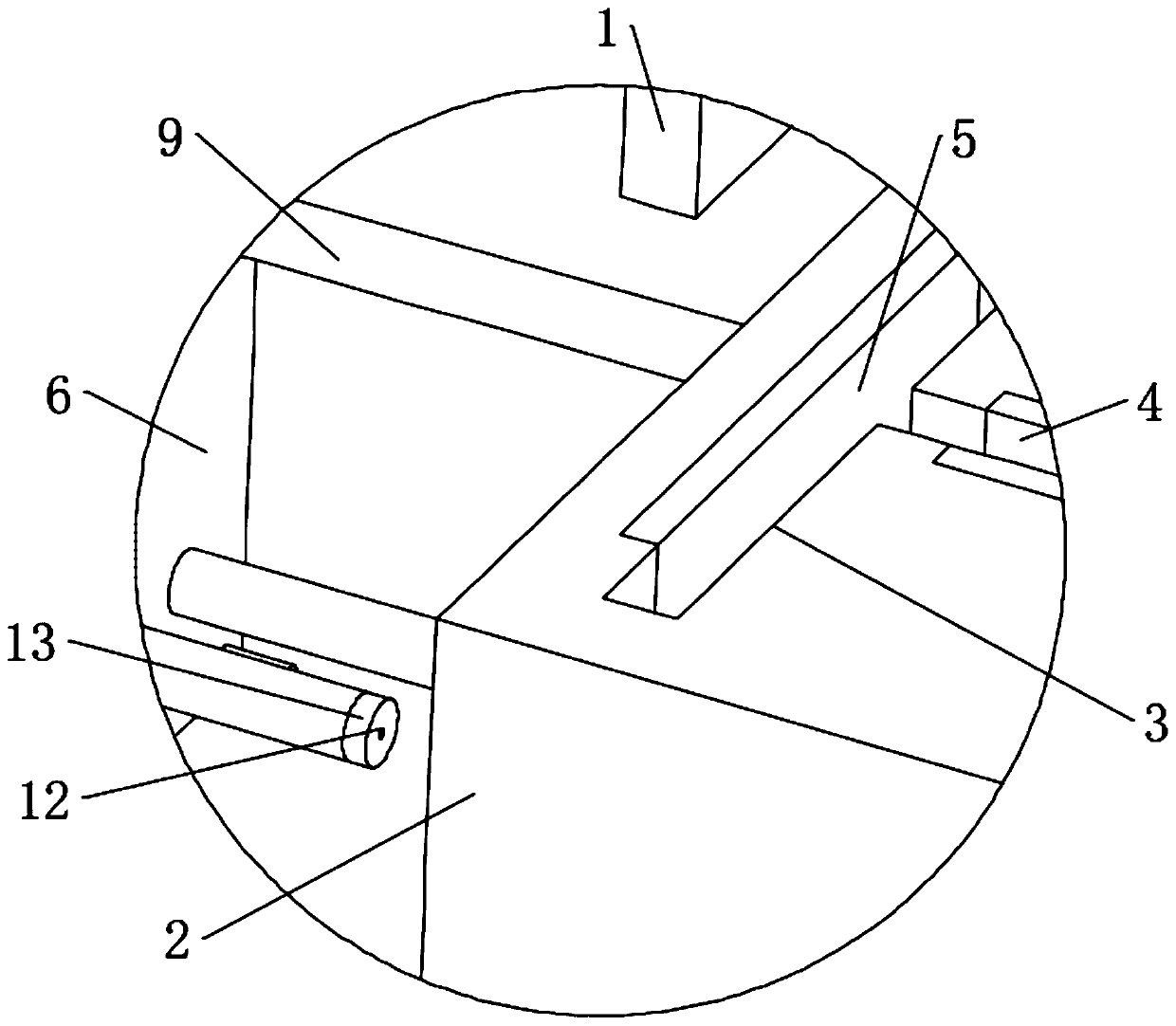

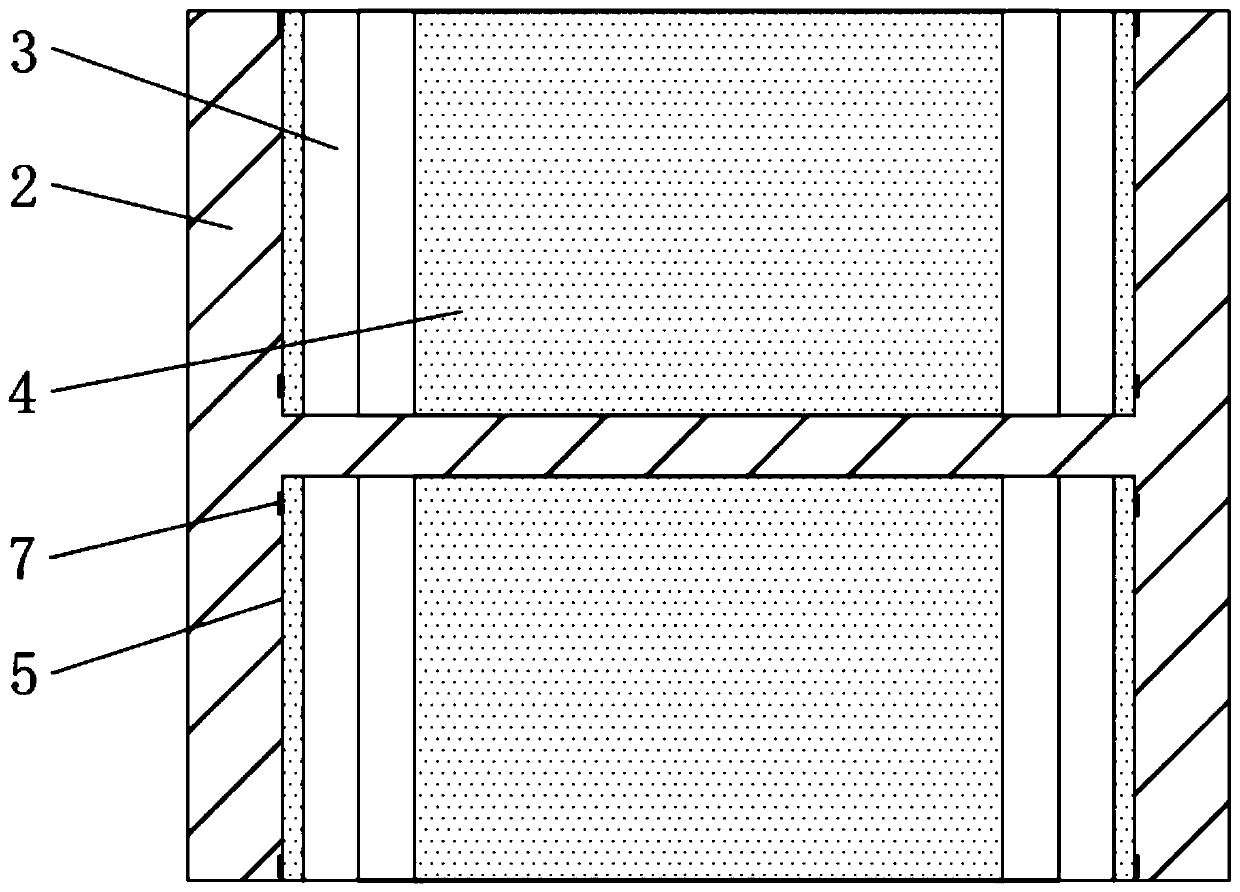

[0047] see Figure 1-3 , an adaptive steel structure connection joint, comprising a pair of steel bodies 1, a wrapped joint is connected between the pair of steel bodies 1, the wrapped joint includes a joint body 2, and a pair of steel bodies 1 is wrapped and connected, and the joint body 2 is up and down H-shaped grooves 3 are excavated at both ends, and the H-shaped grooves 3 and the steel body 1 are matched with each other and have a clearance fit. The H-shaped grooves 3 include a web groove and a pair of wing plate grooves. The first deformation groove, the temperature-sensitive deformation web 4 is fixedly connected in the first deformation groove, and the second deformation groove is dug on the inner wall of a pair of wing plate grooves away from each other, and the temperature-sensitive deformation wing is fixedly connected in the second deformation groove The sheet 5, the temperature-sensing deformation web 4 and the temperature-sensing deformation fin 5 are all made o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com