Solar LED factory building illuminating lamp

A lighting and solar energy technology, applied in the field of lighting, can solve problems such as labor and affecting the lighting effect of lighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

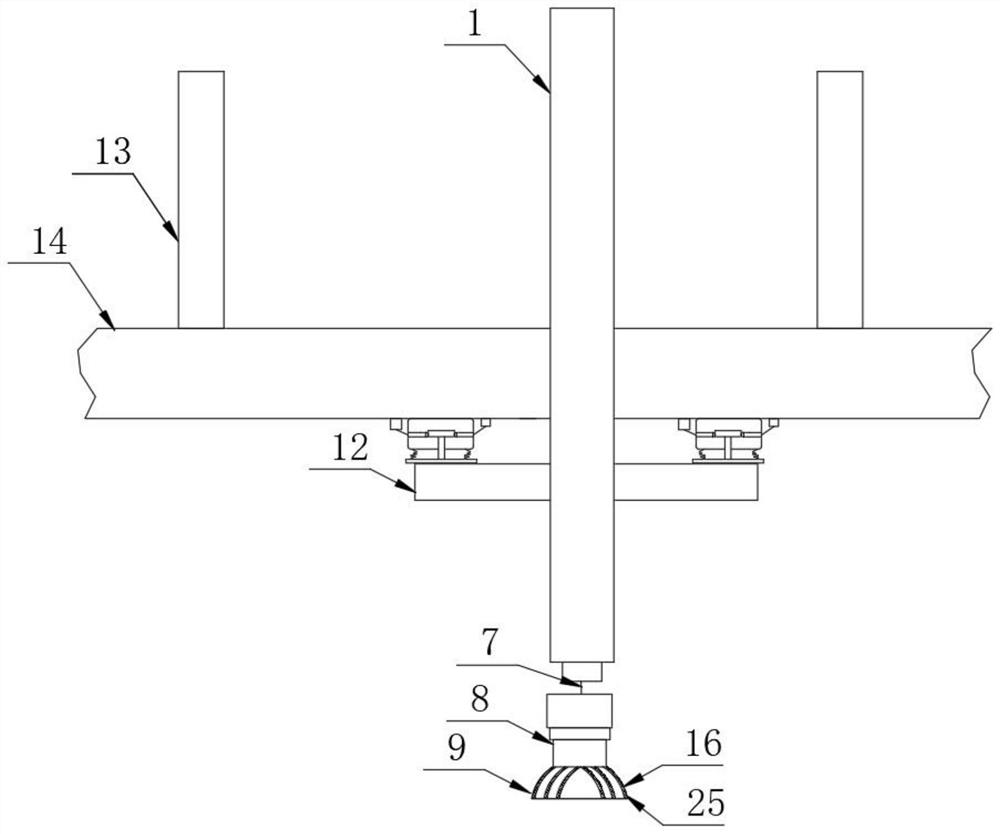

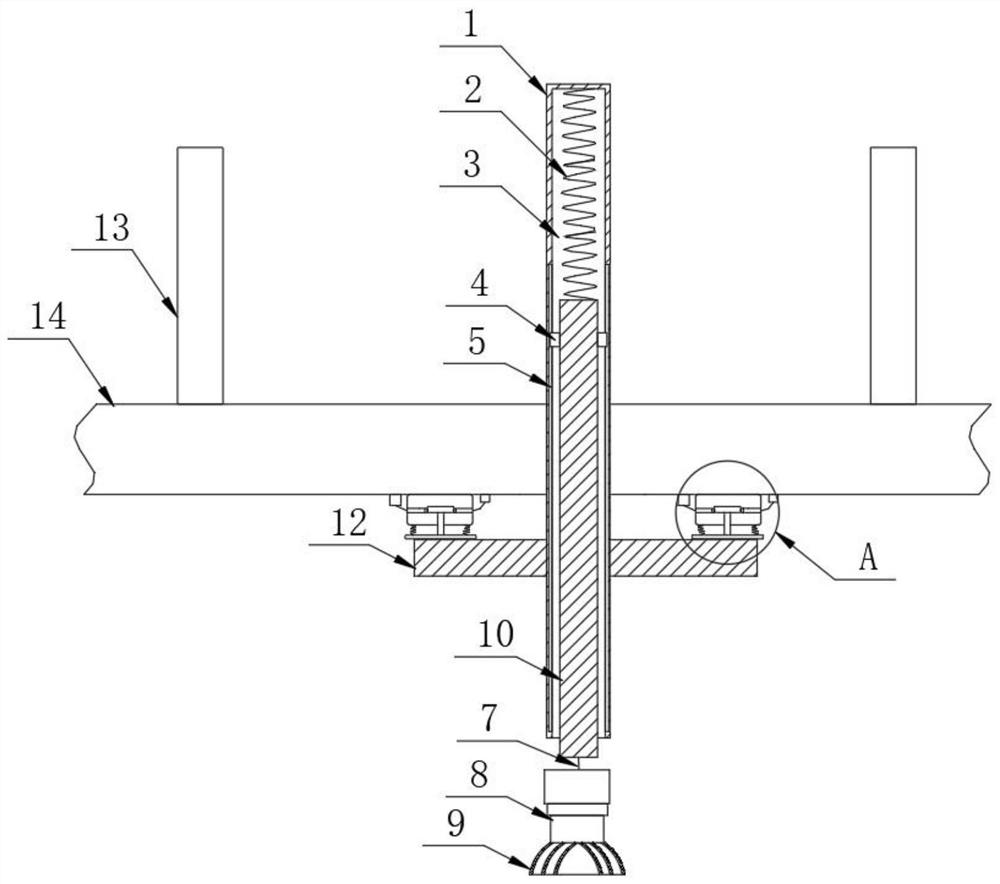

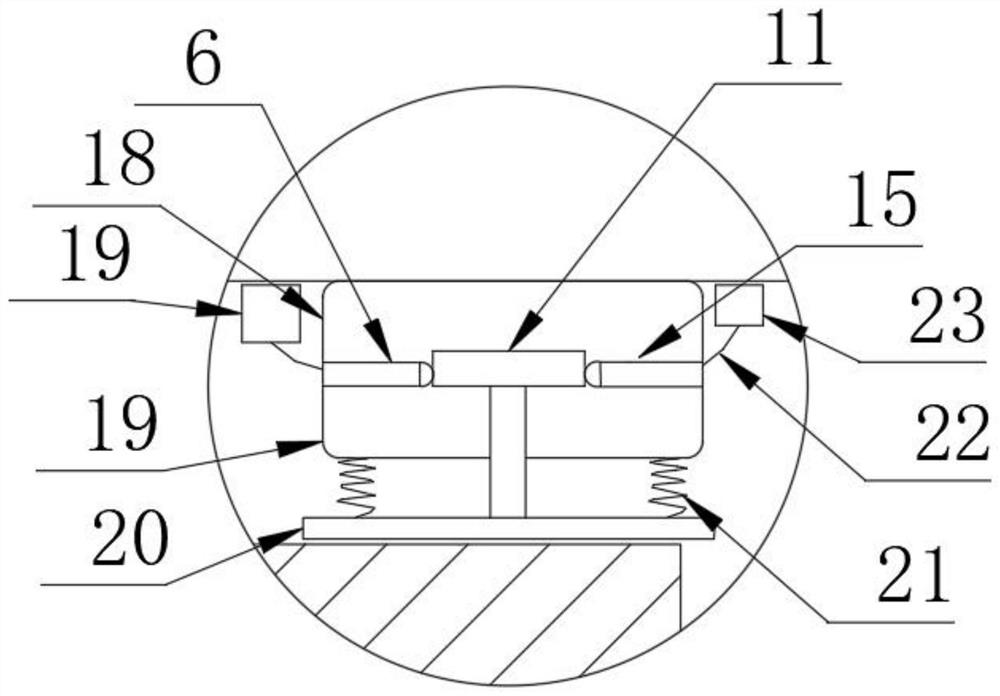

[0032] Such as Figure 1-3 As shown, the solar LED factory building lighting includes a horizontal board 14, and the two sides of the top of the horizontal board 14 are respectively provided with support rods 13. 1. It is characterized in that the bottom surface of the mounting plate 1 is longitudinally provided with a groove 3, the top surface of the groove 3 is fixedly provided with a spring 2, the bottom of the spring 2 is fixedly connected with the movable plate 10, and the two sides of the movable plate 10 are respectively fixedly arranged with Slider 4, two sliders 4 are arranged in two chute 5 respectively, and two chute 5 are set up on both sides in the groove 3 respectively, slider 4 and chute 5 are slidably matched, by being provided with slider 4 and chute 5, so that the movable plate can move up and down stably in the groove, the bottom of the movable plate 10 is connected to the lighting lamp by the chain 7, the chain 7 is made of stainless steel, and the lighting...

Embodiment 2

[0037] Such as Figure 1-4As shown, the solar LED factory building lighting includes a horizontal board 14, and the two sides of the top of the horizontal board 14 are respectively provided with support rods 13. 1. It is characterized in that the bottom surface of the mounting plate 1 is longitudinally provided with a groove 3, the top surface of the groove 3 is fixedly provided with a spring 2, the bottom of the spring 2 is fixedly connected with the movable plate 10, and the two sides of the movable plate 10 are respectively fixedly arranged with Slider 4, two sliders 4 are arranged in two chute 5 respectively, and two chute 5 are set up on both sides in the groove 3 respectively, slider 4 and chute 5 are slidably matched, by being provided with slider 4 and chute 5, so that the movable plate can move up and down stably in the groove, the bottom of the movable plate 10 is connected to the lighting lamp by the chain 7, the chain 7 is made of stainless steel, and the lighting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com