Lens moving mechanism

A lens moving and lens holding technology, applied in electromechanical devices, applications, coatings, etc., can solve problems such as difficulty in predicting the moving and positioning accuracy of the lens holding body, easy loosening of the lens holding body, and reducing the moving and positioning accuracy of the lens holding body. , to achieve the effect of improving the accuracy of mobile positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

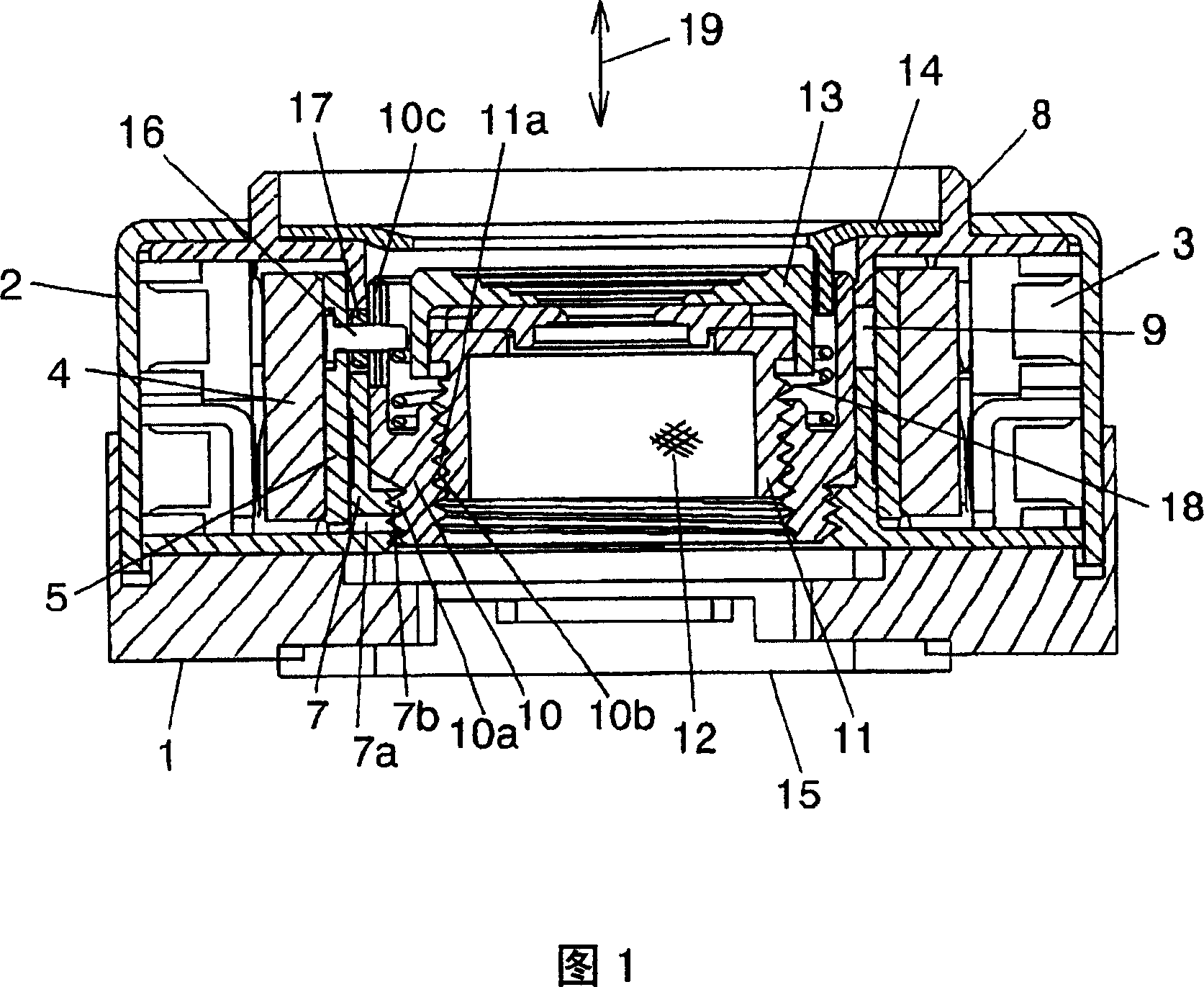

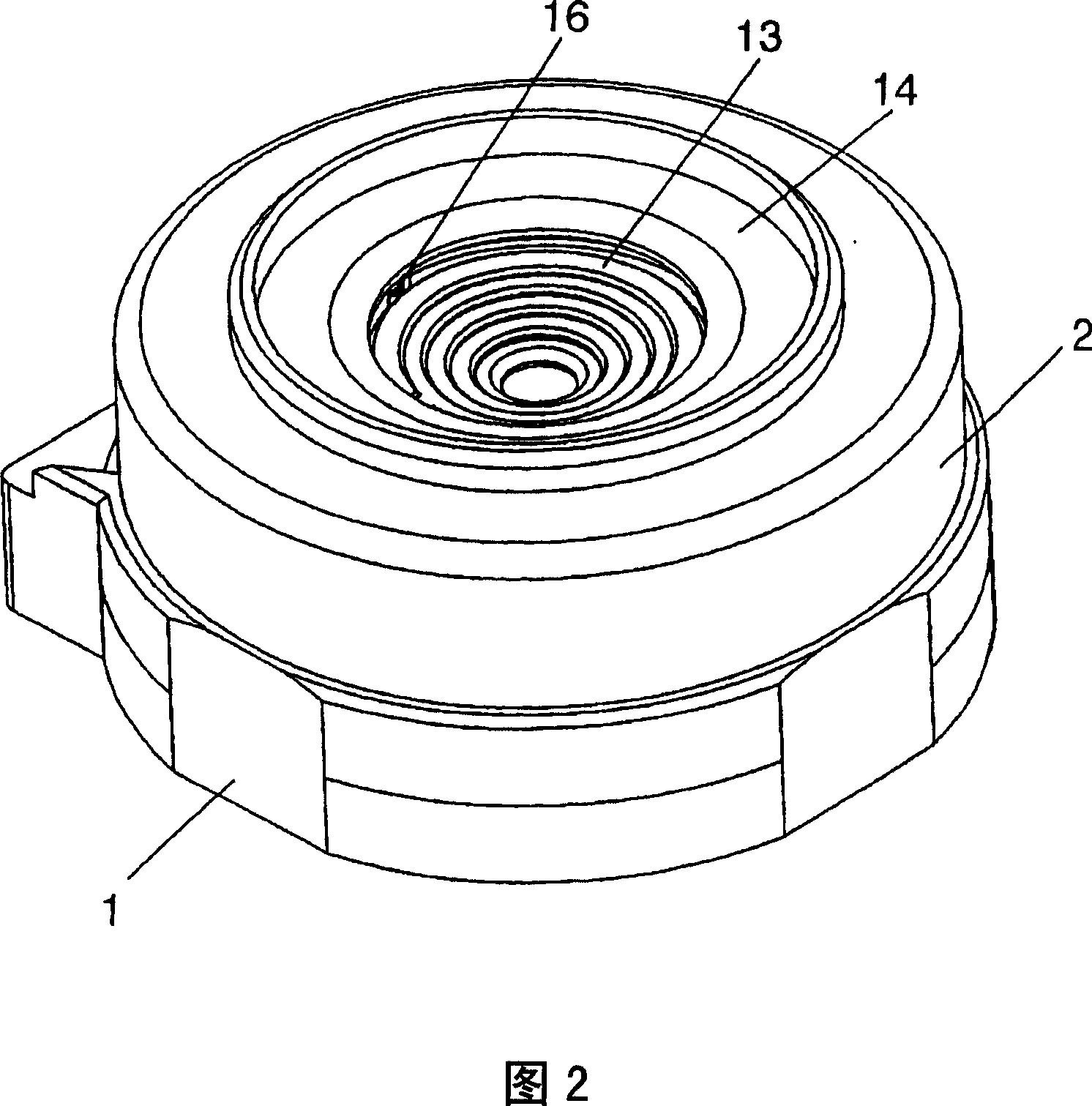

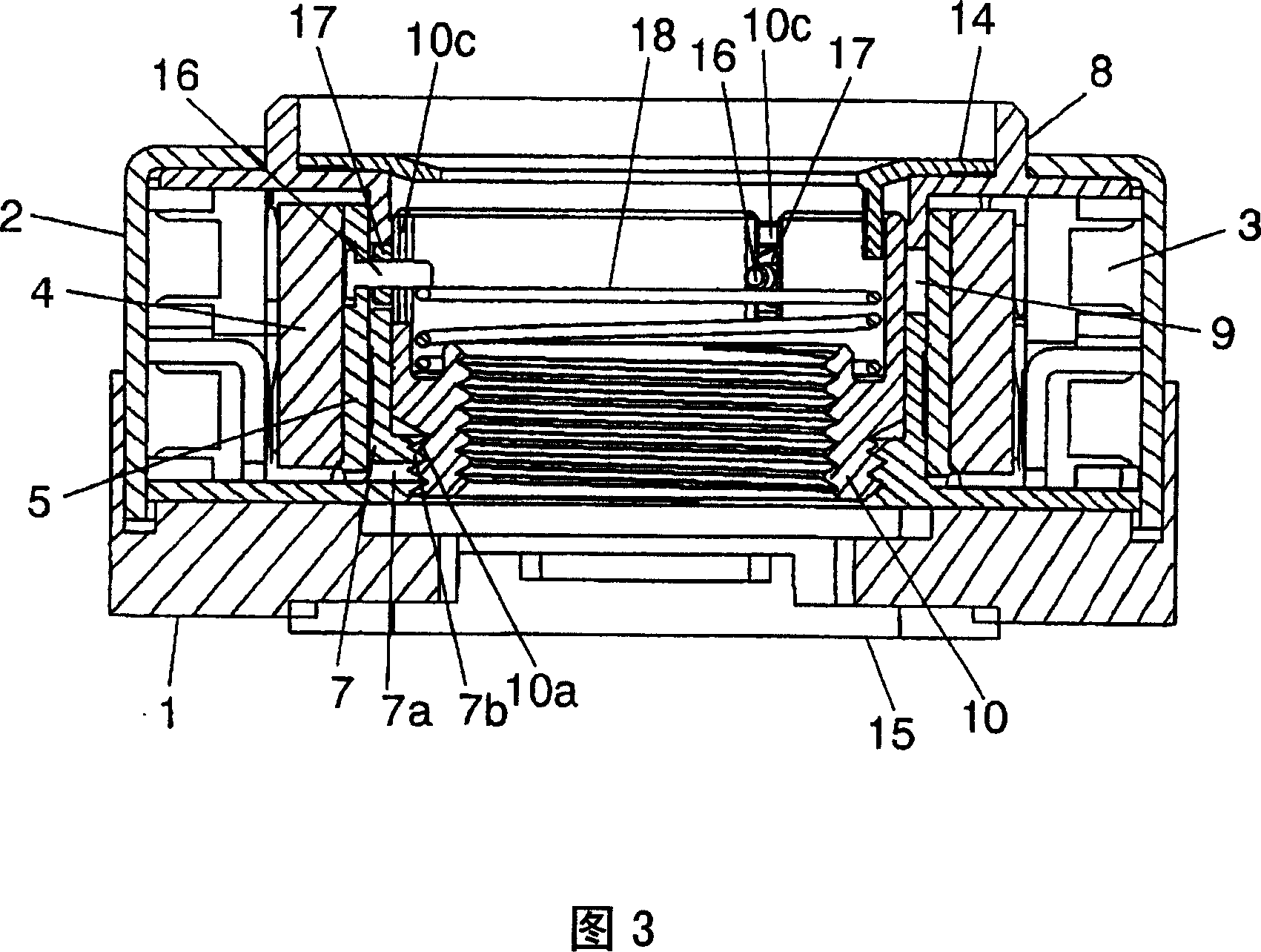

[0030] Next, the best mode for implementing the lens moving mechanism of the present invention will be described with reference to the drawings.

[0031] FIG. 1 is a longitudinal sectional view showing a first embodiment of a lens moving mechanism of the present invention, and FIG. 2 is a perspective view showing an appearance of the first embodiment shown in FIG. 1 .

[0032] 3 is a longitudinal sectional view showing a state where a lens cover, a lens barrel, and a lens are removed from the first embodiment shown in FIG. 1 . 4 is a perspective view showing a state where the stopper plate and lens cover are removed from the first embodiment shown in FIG. A perspective view of the state of the barrel and lens. 6 is a perspective view showing the assembly relationship of the lower guide body, the rotor yoke, the guide pin, the roller member, the cage and the spring member included in the first embodiment shown in FIGS. 2 is a perspective view showing the assembly relationship...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com