Rotary sealing type feeding valve

A technology of rotary sealing and feed valve, applied in valve details, valve devices, cocks including cut-off devices, etc., can solve the problems of feed valve wear, unfavorable air tightness, feed valve blockage, etc., and achieve environmental protection , good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

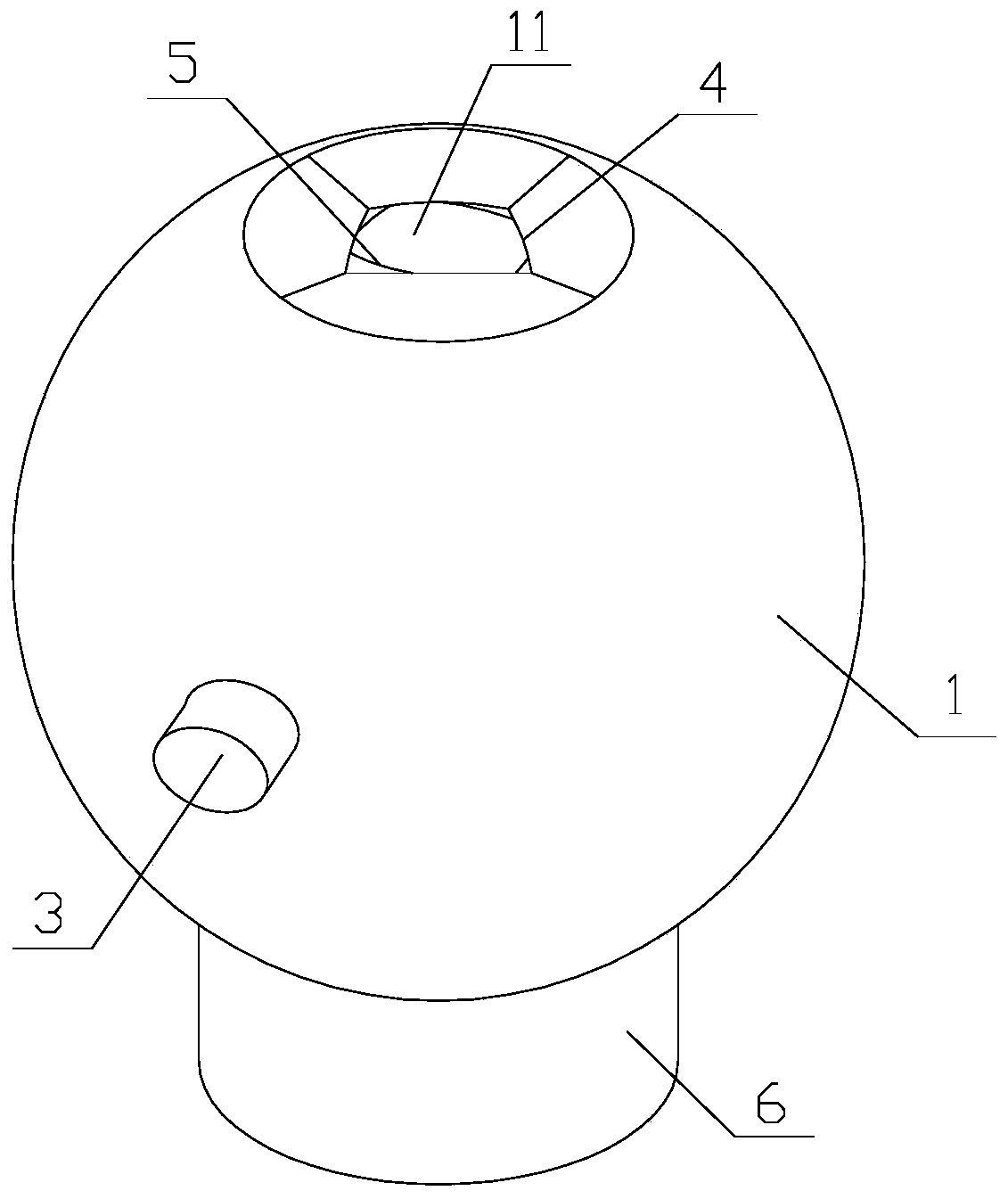

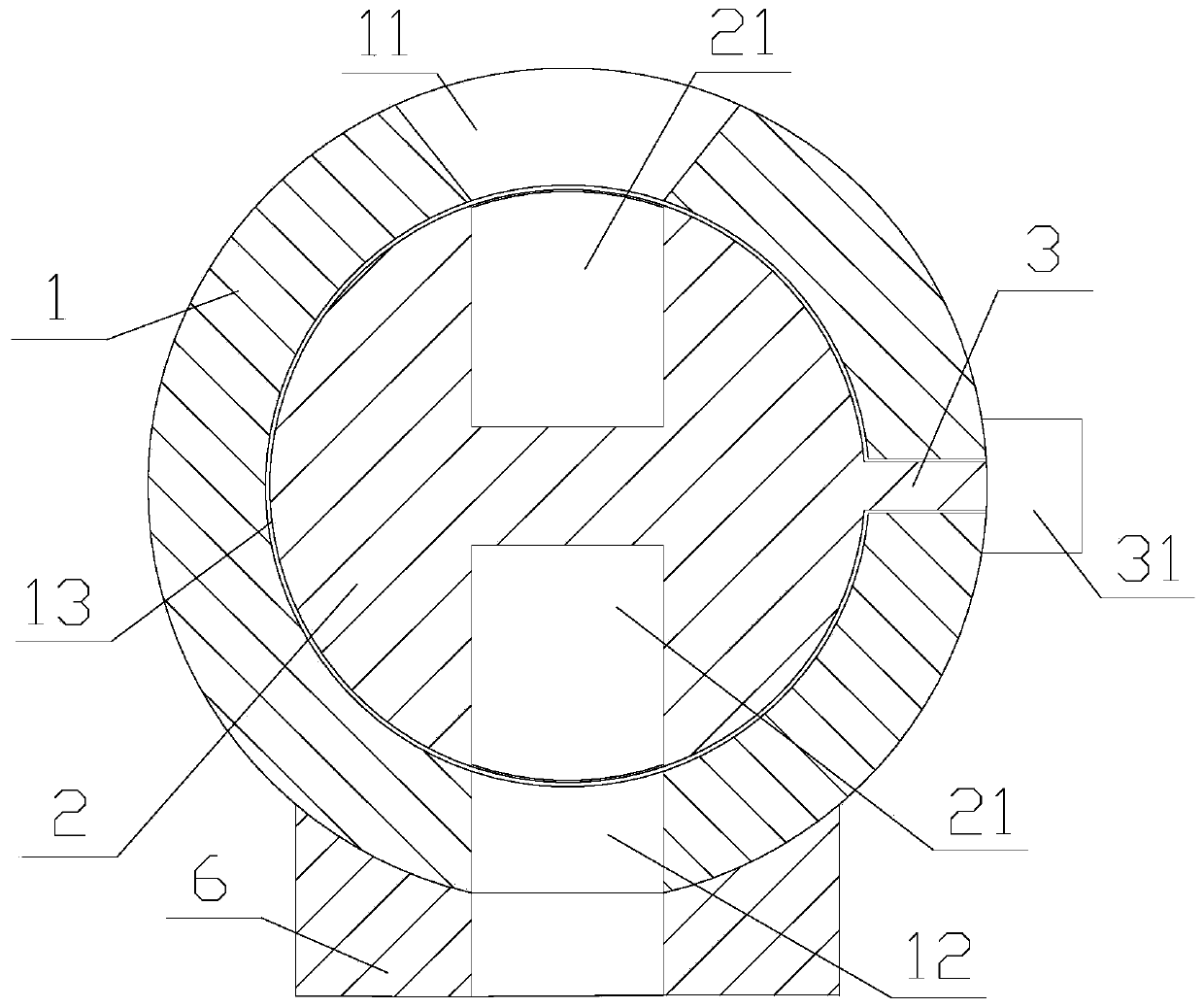

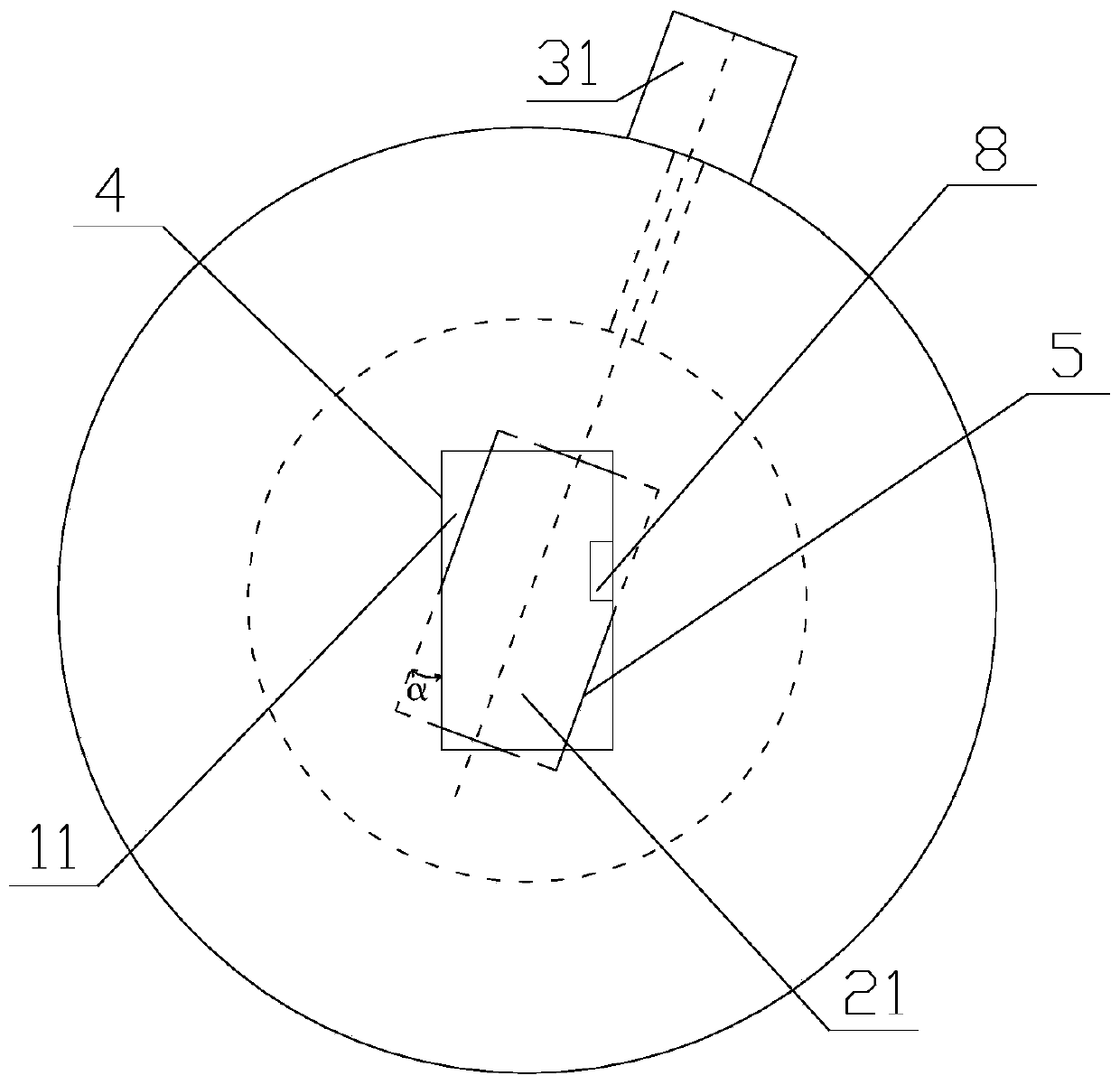

[0036] Such as Figure 1-7 As shown, a rotary sealing feed valve of the present invention includes a valve body 1 and a valve core 2, the top of the valve body 1 is provided with a feed port 11, the bottom is provided with a discharge port 12, and the center of the valve body 1 is provided with Spherical cavity 13, the valve core 2 is arranged in the spherical cavity 13 and matched with the spherical cavity 13, the valve core 2 is provided with a feeding groove 21, a rotating shaft 3 is connected to the valve core 2, and the other end of the rotating shaft 3 After passing through the valve body 1, it is connected with a driving mechanism 31, and the driving mechanism 31 drives the rotating shaft 3 and the valve core 2 to rotate.

[0037] The spherical center of the valve core 2 is located on the axis of the rotating shaft 3, and the rotating shaft 3 is arranged horizontally.

[0038] Further, the bottom edge of the feed port 11 is polygon one 4, the cross section of the feed ...

Embodiment 2

[0040] Such as Figure 1-7 As shown, a rotary sealing feed valve of the present invention includes a valve body 1 and a valve core 2, the top of the valve body 1 is provided with a feed port 11, the bottom is provided with a discharge port 12, and the center of the valve body 1 is provided with Spherical cavity 13, the valve core 2 is arranged in the spherical cavity 13 and matched with the spherical cavity 13, the valve core 2 is provided with a feeding groove 21, a rotating shaft 3 is connected to the valve core 2, and the other end of the rotating shaft 3 After passing through the valve body 1, it is connected with a driving mechanism 31, and the driving mechanism 31 drives the rotating shaft 3 and the valve core 2 to rotate.

[0041] The spherical center of the valve core 2 is located on the axis of the rotating shaft 3, and the rotating shaft 3 is arranged horizontally.

[0042] The bottom edge of the feed port 11 and the cross-section of the feed trough 21 are rectangular...

Embodiment 3

[0048] Such as Figure 8 As shown, a rotary sealing feed valve of the present invention includes a valve body 1 and a valve core 2, the top of the valve body 1 is provided with a feed port 11, the bottom is provided with a discharge port 12, and the center of the valve body 1 is provided with Cylindrical cavity 7, the spool 2 is arranged in the cylindrical cavity 7 and matched with the cylindrical cavity 7, the spool 2 is provided with a feeding groove 21, connected to a rotating shaft 3 on the spool 2, the rotating shaft 3 The other end passes through the valve body 1 and is connected to a driving mechanism 31, and the driving mechanism 31 drives the rotating shaft 3 and the valve core 2 to rotate.

[0049] Further, the axis of the rotating shaft 3 coincides with the axis of the cylindrical cavity 7, the rotating shaft 3 is arranged horizontally, the axis of the feeding trough 21 is perpendicular to the rotating shaft 3, the bottom edge of the feeding port 11 is polygon-4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com