Drying method and drying device

A drying device and drying method technology, applied in the combustion method, drying solid materials, heating to dry solid materials, etc., can solve the problems of increased equipment cost and operating cost, and achieve the effect of effective adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

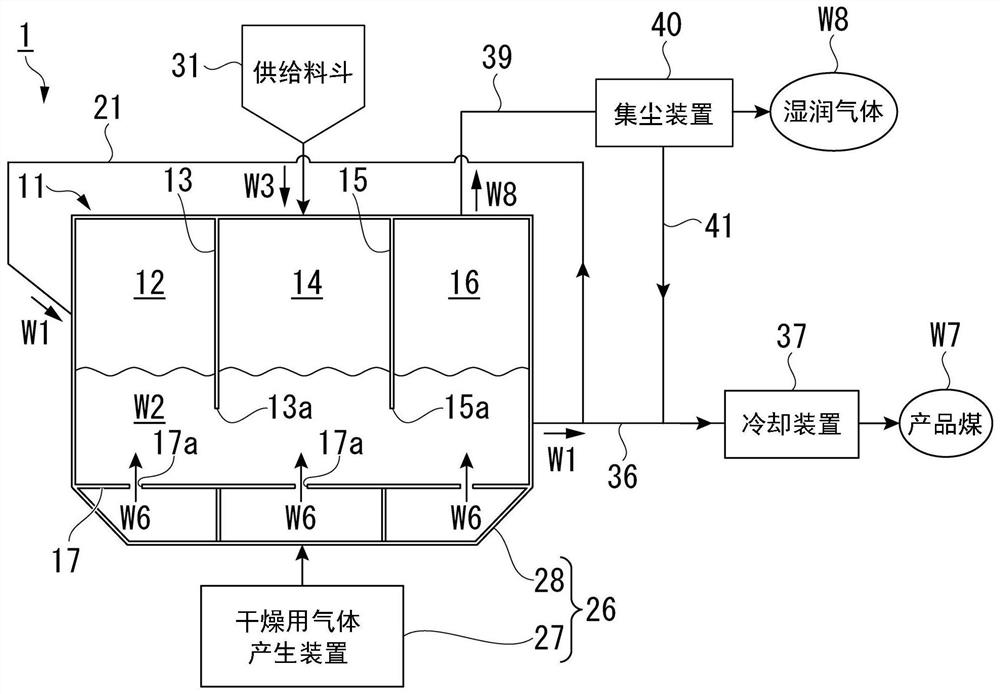

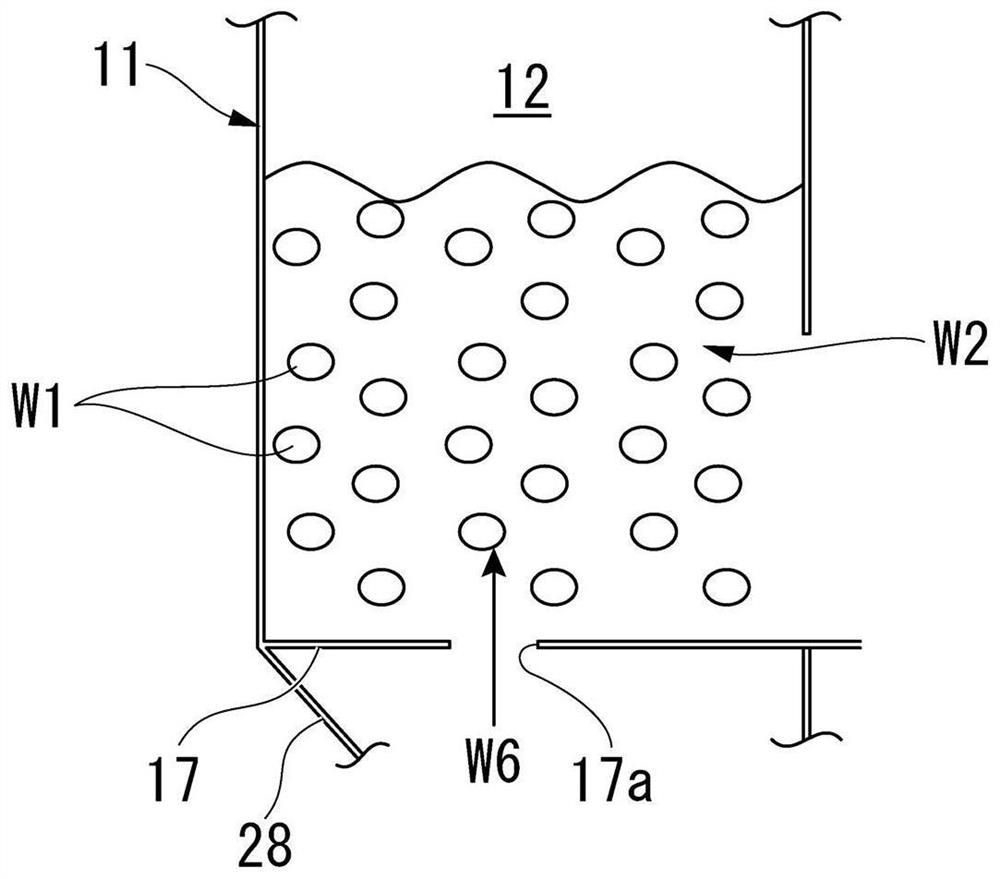

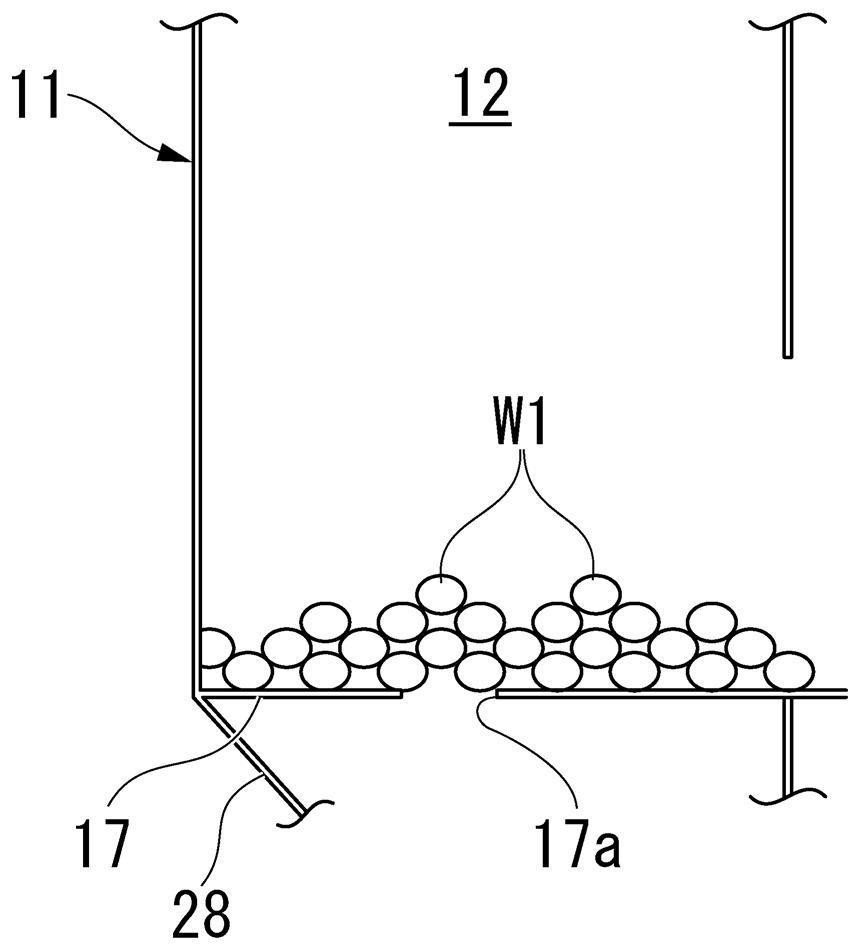

[0062] Below, refer to Figure 1 to Figure 3 A first embodiment of the drying device according to the present invention will be described. This drying device is used to continuously dry coal (object to be dried) with a high water content such as lignite.

[0063] Such as figure 1 As shown, the drying device 1 of this embodiment includes: a drying chamber 11; a return pipe (pre-dried product supply unit) 21 for supplying dry coal (pre-dried product) W1 obtained by drying coal in advance to the drying chamber 11; The drying part 26 dries the dried coal W1 supplied to the drying chamber 11 while being further fluidized to become a fluidized coal (fluidized pre-dried product) W2; Mixed coal W3 in chemical coal W2.

[0064] Drying chamber 11 has: the 1st chamber (fluidization chamber) 12; The 2nd chamber (mixing chamber) 14, divides with the 1st chamber 12 by the partition 13; And the 3rd chamber 16, passes the partition 15 and the 2nd chamber 14 divided. The first chamber 12,...

no. 2 Embodiment approach

[0099] Second, refer to Figure 4 to Figure 8 Although the second embodiment of the present invention will be described, the same reference numerals will be attached to the same parts as those in the above-mentioned embodiment to omit the description, and only the different points will be described. The drying device of the present embodiment is used to dry coal W3 in batches. Such as Figure 4 As shown, the drying device 2 of this embodiment has a drying chamber 51 formed in a square tube shape. The drying chamber 51 is arranged such that the axis thereof extends in the vertical direction.

[0100] The lower end of the drying chamber 51 is connected to a drying gas chamber 62 via a dispersion plate 61 . The drying gas W6 is supplied to the drying gas chamber 62 from the drying gas generator 27 (not shown). In addition, in this embodiment, water vapor is used as the drying gas W6. The fluidized portion 63 is constituted by the drying gas chamber 62 and the drying gas gene...

no. 3 Embodiment approach

[0130] Second, refer to Figure 9 to Figure 15 Although the third embodiment of the present invention will be described, the same reference numerals will be attached to the same parts as those in the above-mentioned embodiment to omit the description, and only the different points will be described.

[0131] Such as Figure 9As shown, the drying device 3 of the present embodiment includes a sieving classifier (classification unit) 71 and a classified coal flow rate regulator 72 in addition to the respective configurations of the drying device 1 of the first embodiment.

[0132] The sieve classifier 71 classifies the dried coal W1 dried in the drying chamber 11 based on the particle size (particle diameter) of the dried coal W1. The sieving and classifying machine 71 is installed at the connecting portion between the product conveyance pipe 36 and the return pipe 21 . The sieve classifier 71 supplies only the dry large-diameter coal (pre-dried large-diameter material) W10 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com