Die for brake disc production

A technology of brake discs and molds, which is applied in the field of brake discs, can solve the problems of general cooling effect and lower production efficiency, and achieve the effects of improving cooling efficiency, increasing production efficiency, and strengthening cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

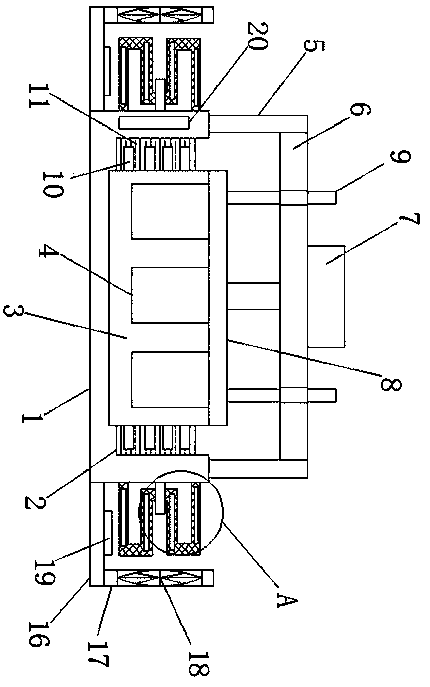

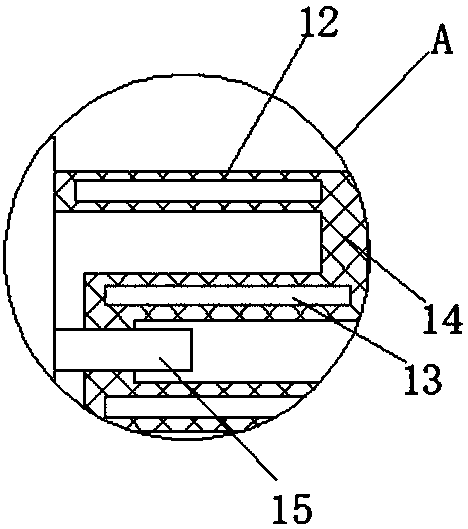

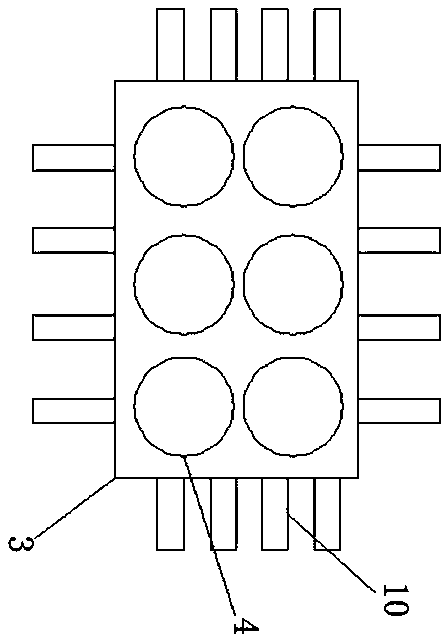

[0025] Embodiment: when the brake disc is produced, the pouring liquid is poured into the die 4, the cylinder 7 is started, and the cylinder 7 pushes the punch 8 to move, so that the punch 8 and the die 4 are matched, and through the heat conducting plate 10 provided, The heat inside the die 4 is introduced into the inside of the cooling liquid 11, and the cooling liquid 11 is circulated into the cooling pipe 12 by starting the delivery pump 15, and the cooling liquid 11 is cooled by the heat dissipation fins 13 and the heat dissipation silica gel 14 provided outside the cooling pipe 12. The internal heat is exported. When the temperature near the cooling pipe 12 is too high, when the temperature sensor 19 of the CWDZ11 type senses the temperature is too high, the MSP430 single-chip microcomputer controls the fan 18 to start, and the heat near the cooling pipe 12 is blown away. The design is simple and fast , can cast multiple concave molds at the same time, which improves prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com