Quick-dismounting quick-changing type small SLM printer

A printer and quick-change technology, applied in the field of 3D printing, can solve the problems of high-cost metal 3D printing technology, achieve better smoke removal effect, facilitate powder cleaning, and improve equipment working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with principle of the present invention, accompanying drawing and embodiment the present invention is further described

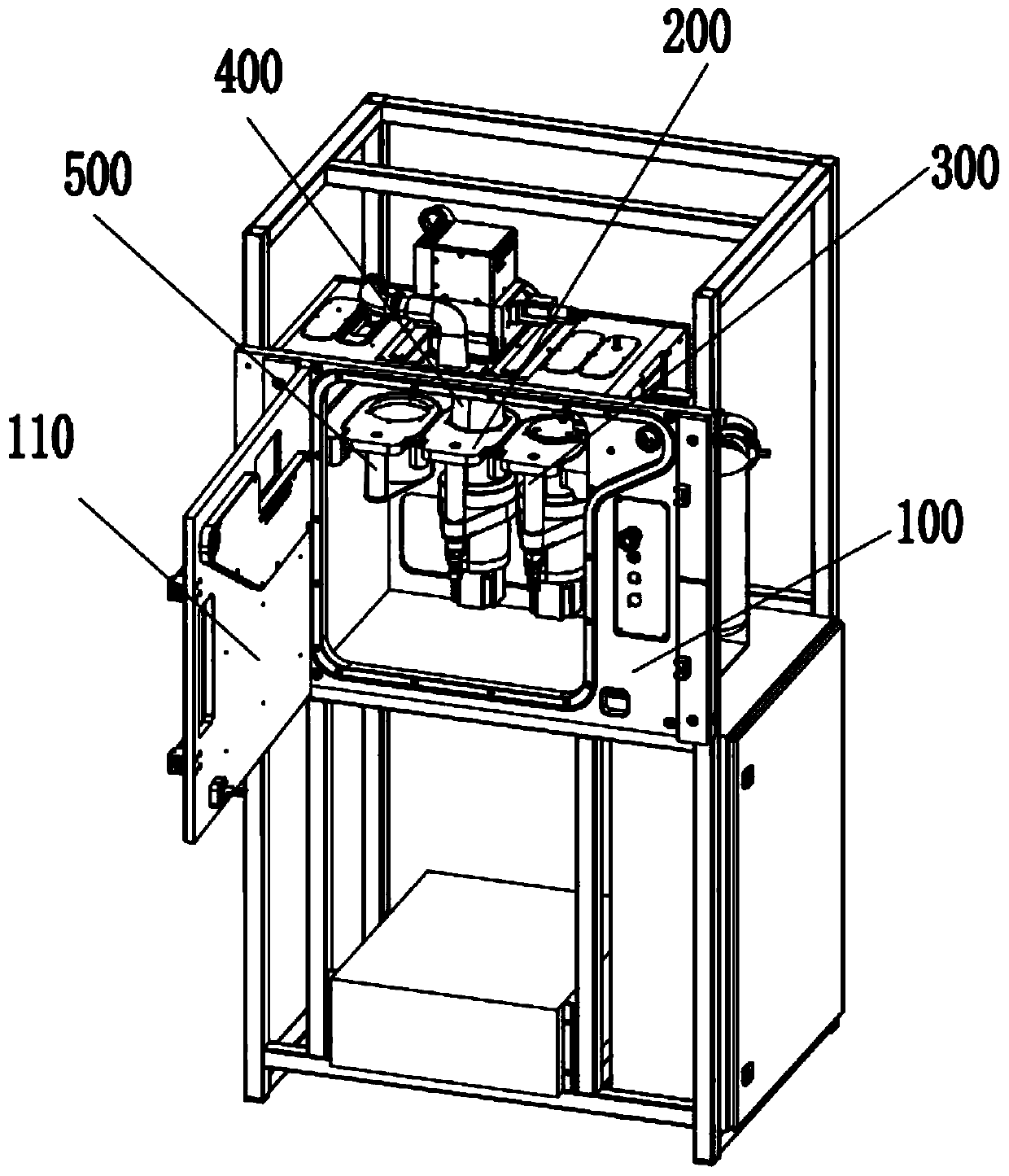

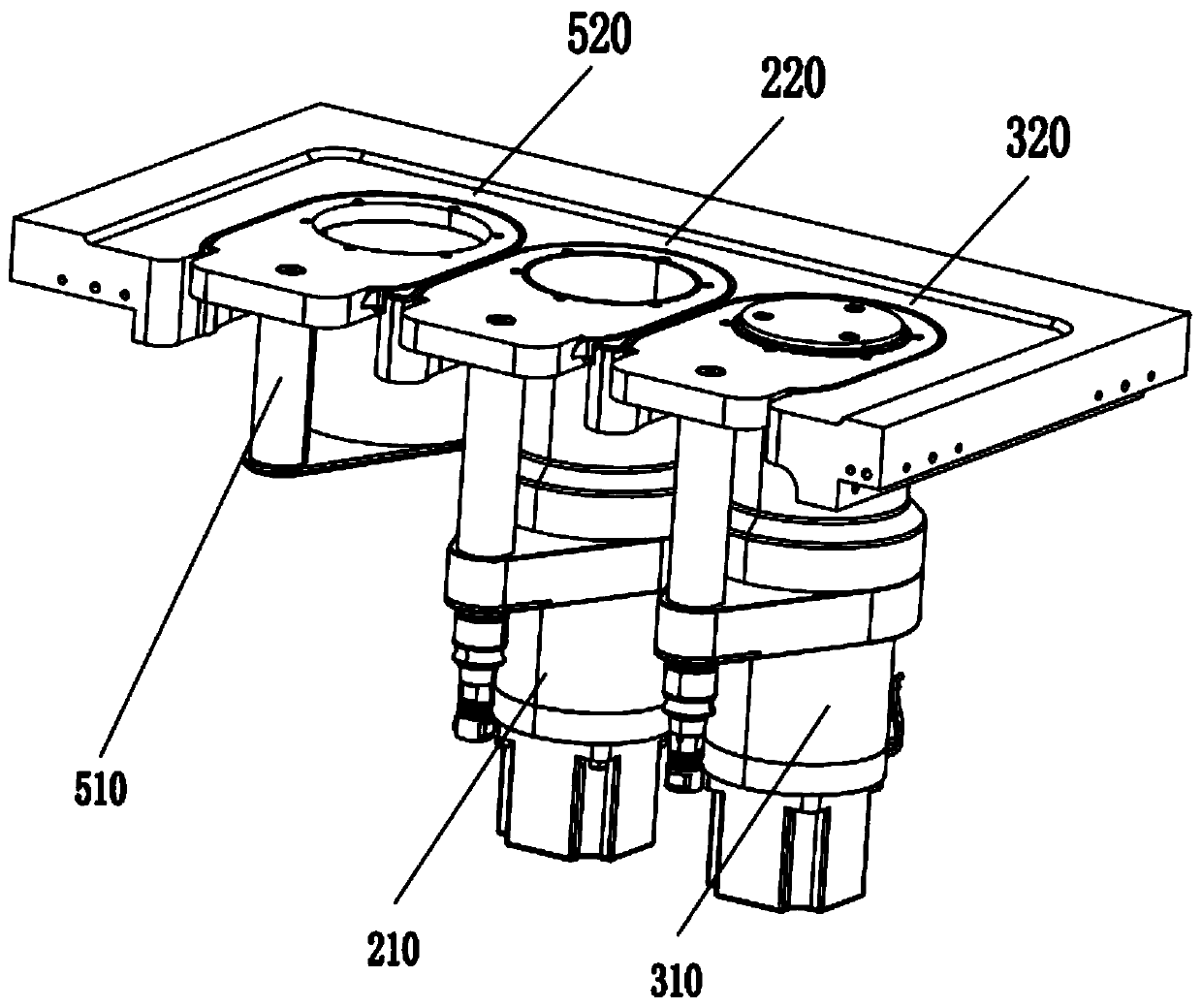

[0032] see Figure 1 to Figure 4 , as shown in the legend, a quick-release and quick-change small SLM printer, including:

[0033] The processing chamber 100 is provided with a pick-and-place port and a main air inlet, the above-mentioned pick-and-place port is provided with a pick-and-place door 110, and the above-mentioned main air inlet is connected with an air outlet of a protective gas supply device (not shown in the figure);

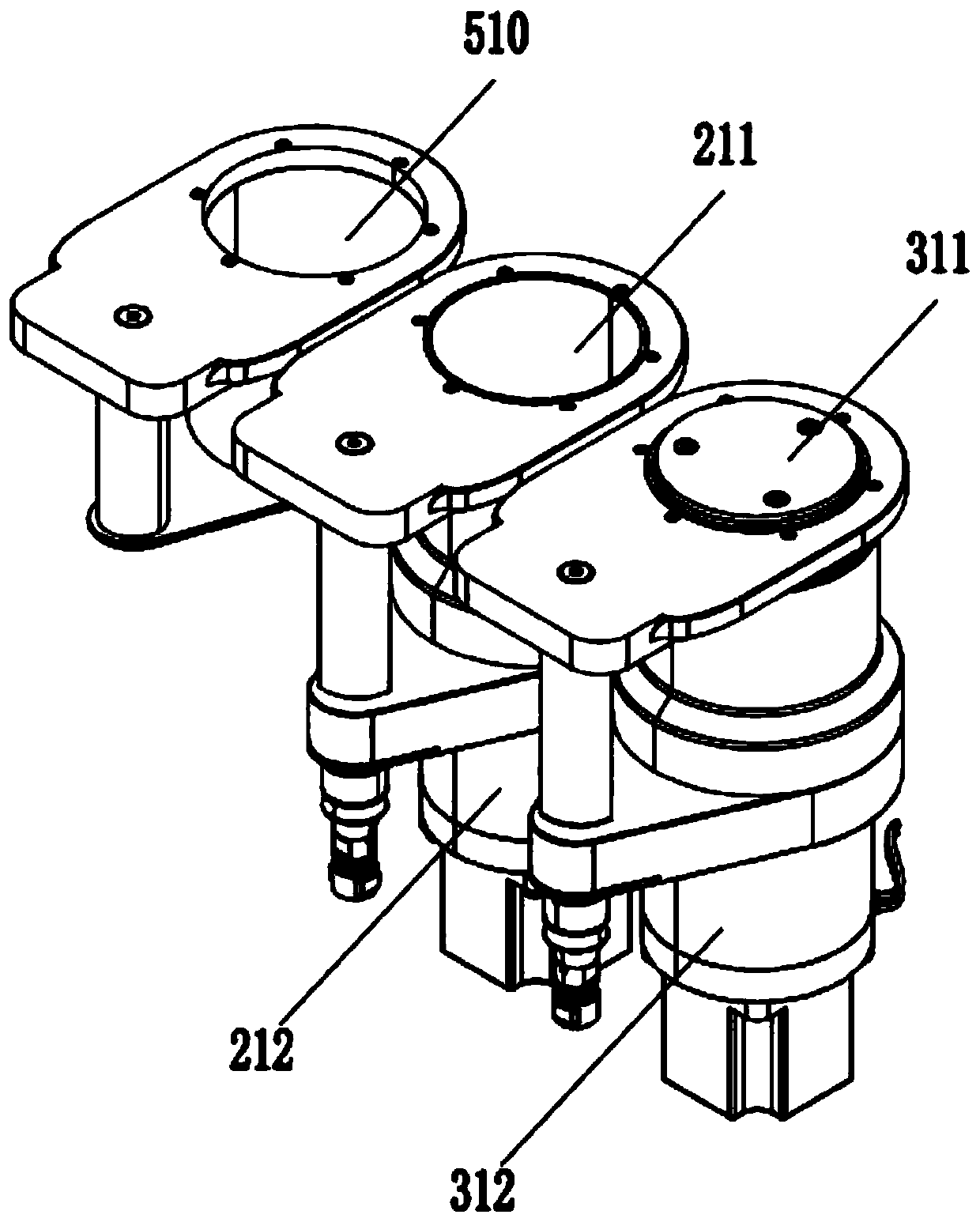

[0034] The molding device 200, which is arranged in the processing chamber 100, includes a molding cylinder 210 for accommodating metal powder and a bracket A220 for installing the molding cylinder 210;

[0035] The powder supply device 300, which is located in the processing chamber 100, includes a powder supply cylinder 310 for accommodating metal powder and a bracket B320 for installing the powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com