Processing device and method for mounting same

A technology for processing equipment and workpieces, applied in metal processing equipment, metal processing, wood processing appliances, etc., can solve problems such as increasing the cost of processing equipment, achieve rapid replaceability, eliminate error sources, and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A preferred embodiment of the invention is described below with the aid of the drawings. Modifications of certain individual features may each independently be combined with each other to form new embodiments. Accordingly, the described examples of embodiments should not be considered as limiting, but mainly serve as a descriptive explanation of the invention.

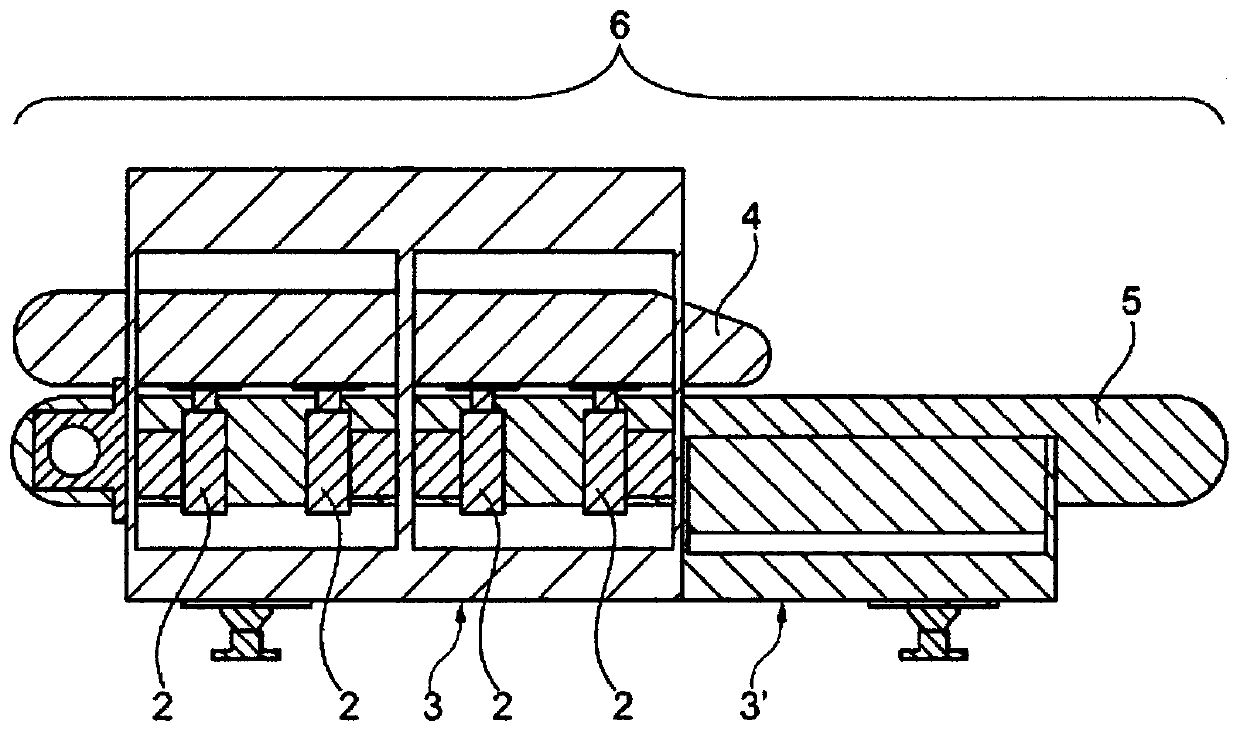

[0042] figure 1The processing device 6 is shown in side view, wherein the processing device 6 is formed as a through-feed device. figure 1 The processing equipment shown in consists of the elements described below.

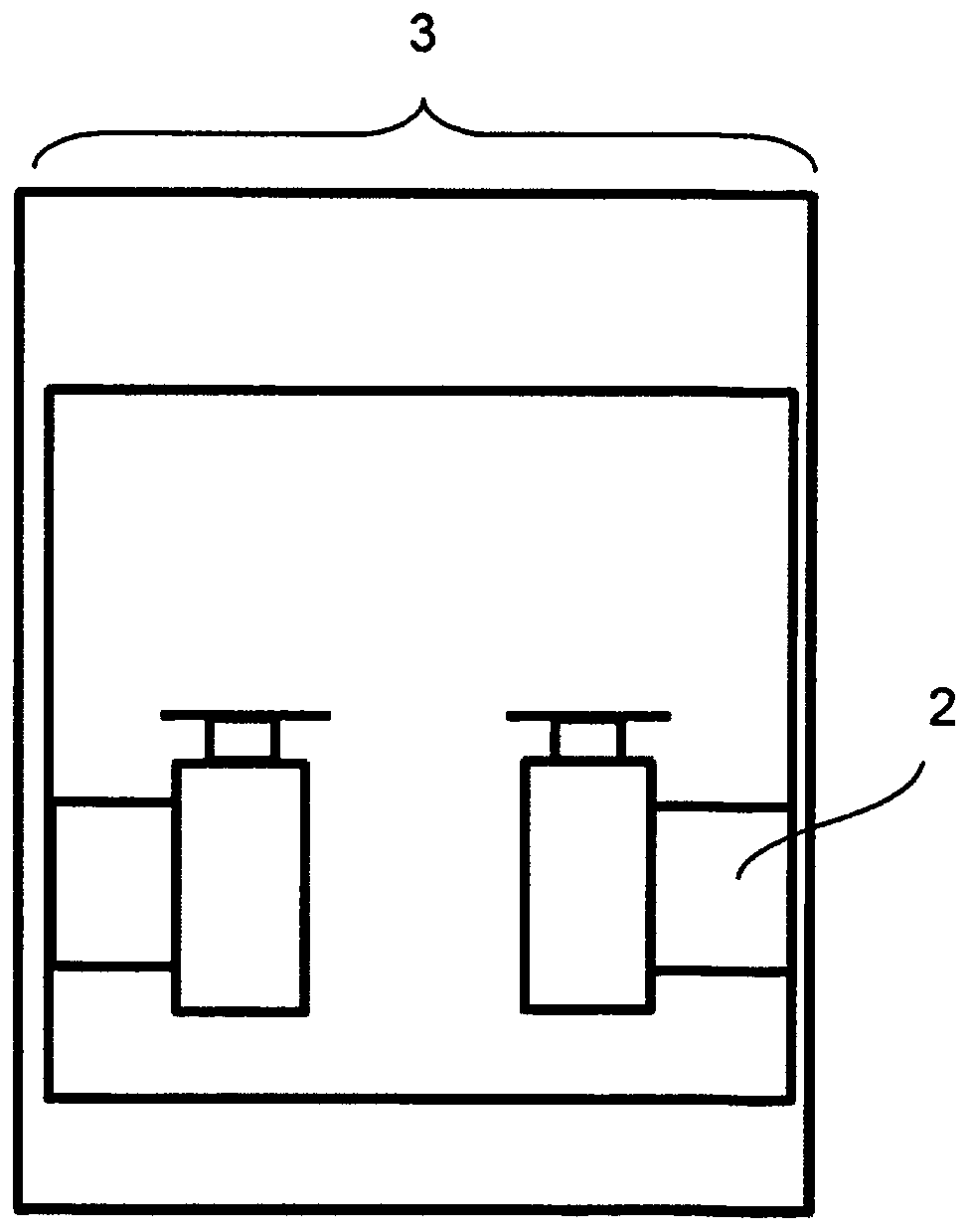

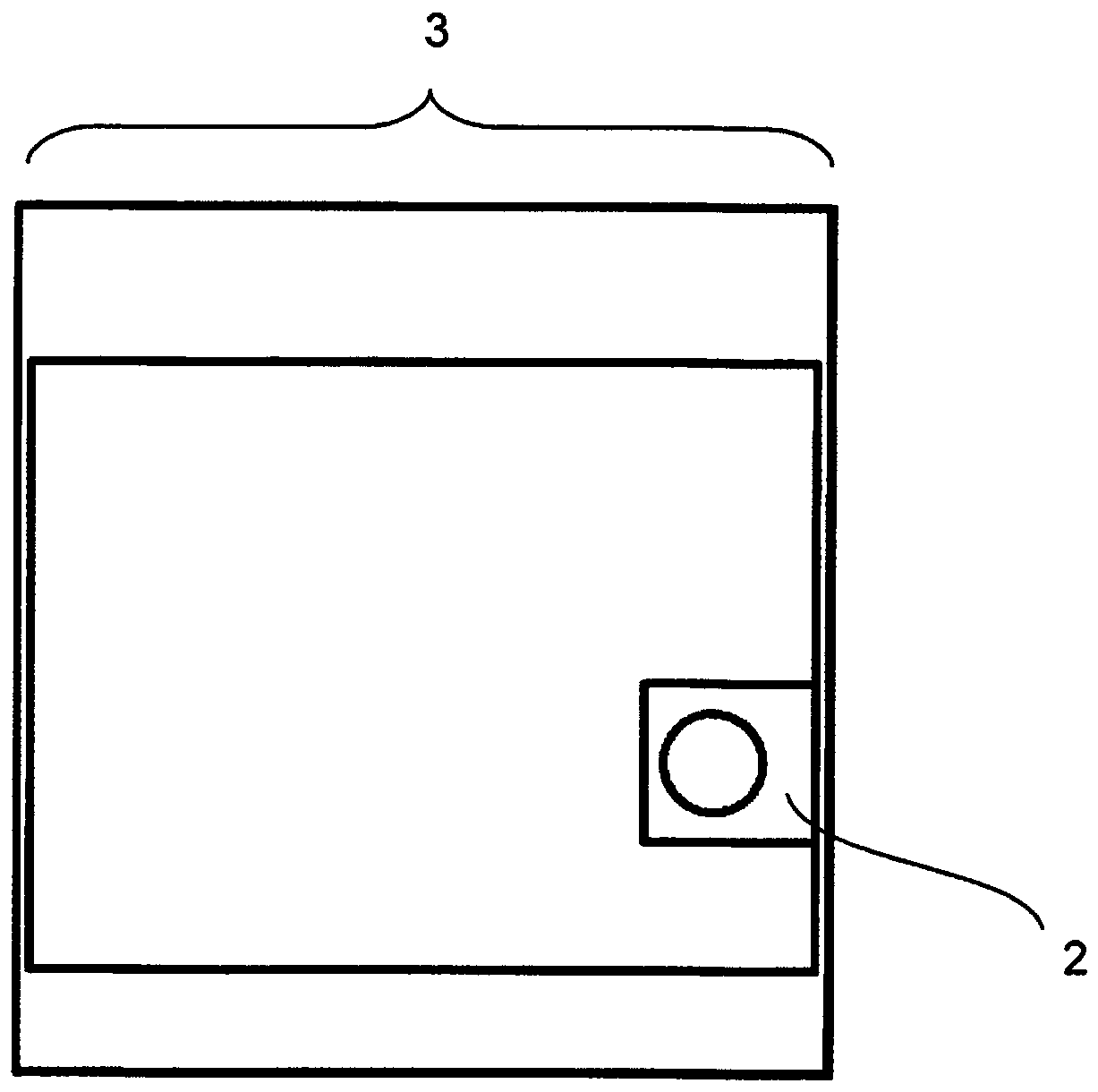

[0043] The processing plant 6 comprises a first module 3 and a second module 3', wherein the modules 3, 3' are connected to each other at a junction. In this respect, a continuous chain guide 5 of the conveyor device is provided. Furthermore, a top pressure device 4 is provided.

[0044] During the assembly of the processing plant 6 the modules are aligned, joined together and then joined toget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com