Filter element and filter system having filter element

A filter and element technology, which is applied in the filter system and air filter field where the filter element is installed, can solve the problems of coarse suspended particles clogging the filter medium, suspended particles damaging the medium, etc., and achieve structural space saving and low-cost production effect of technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

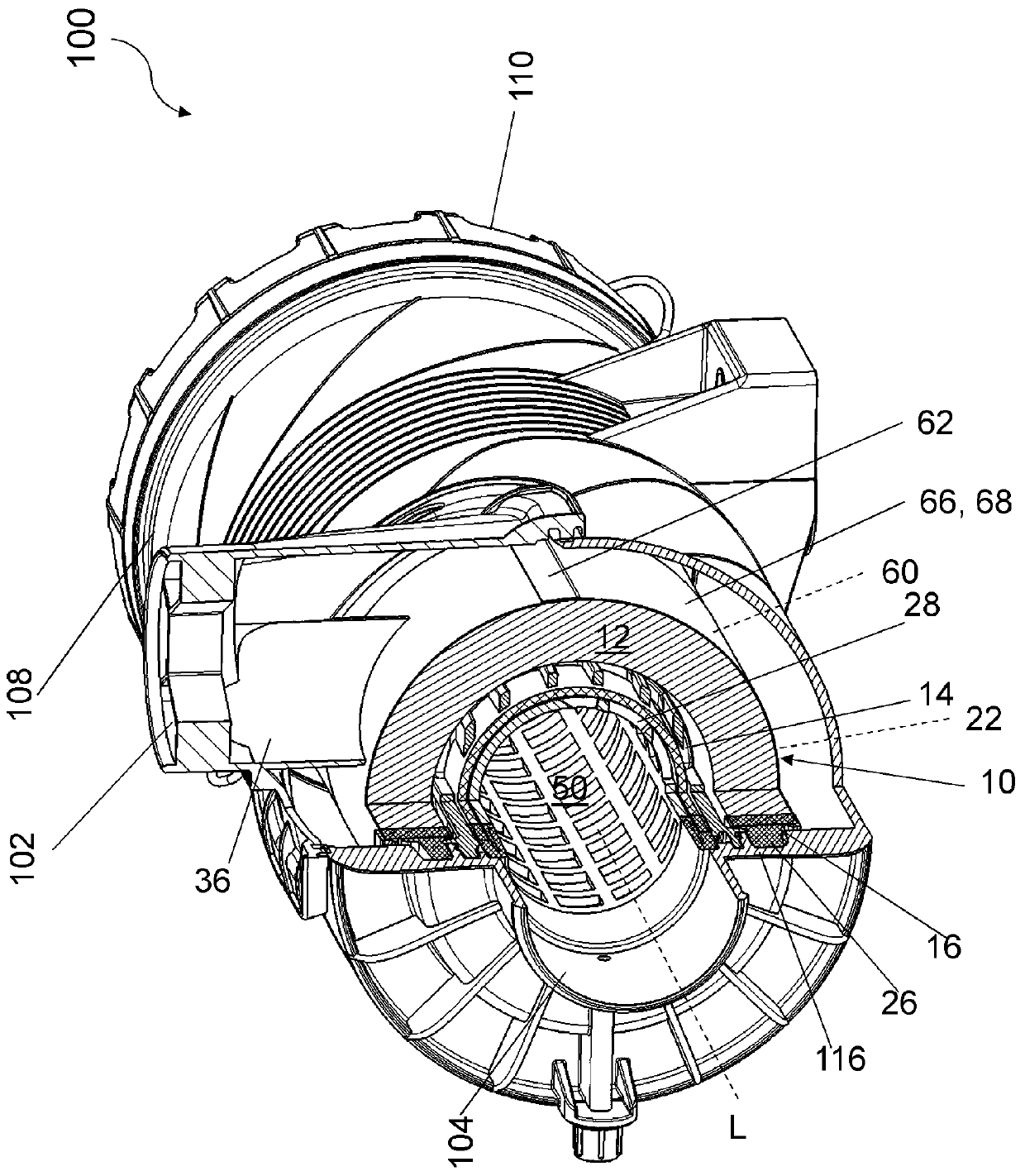

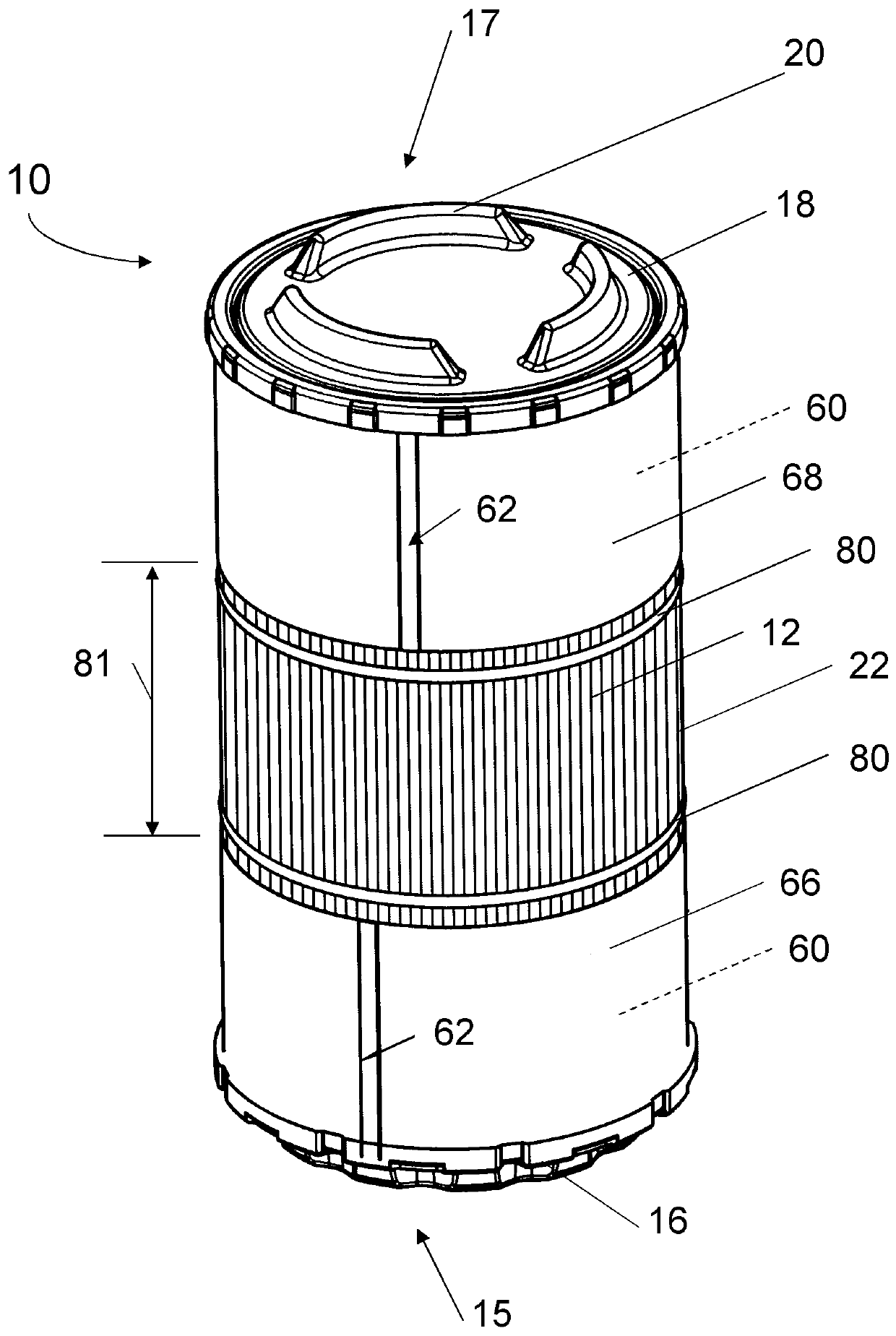

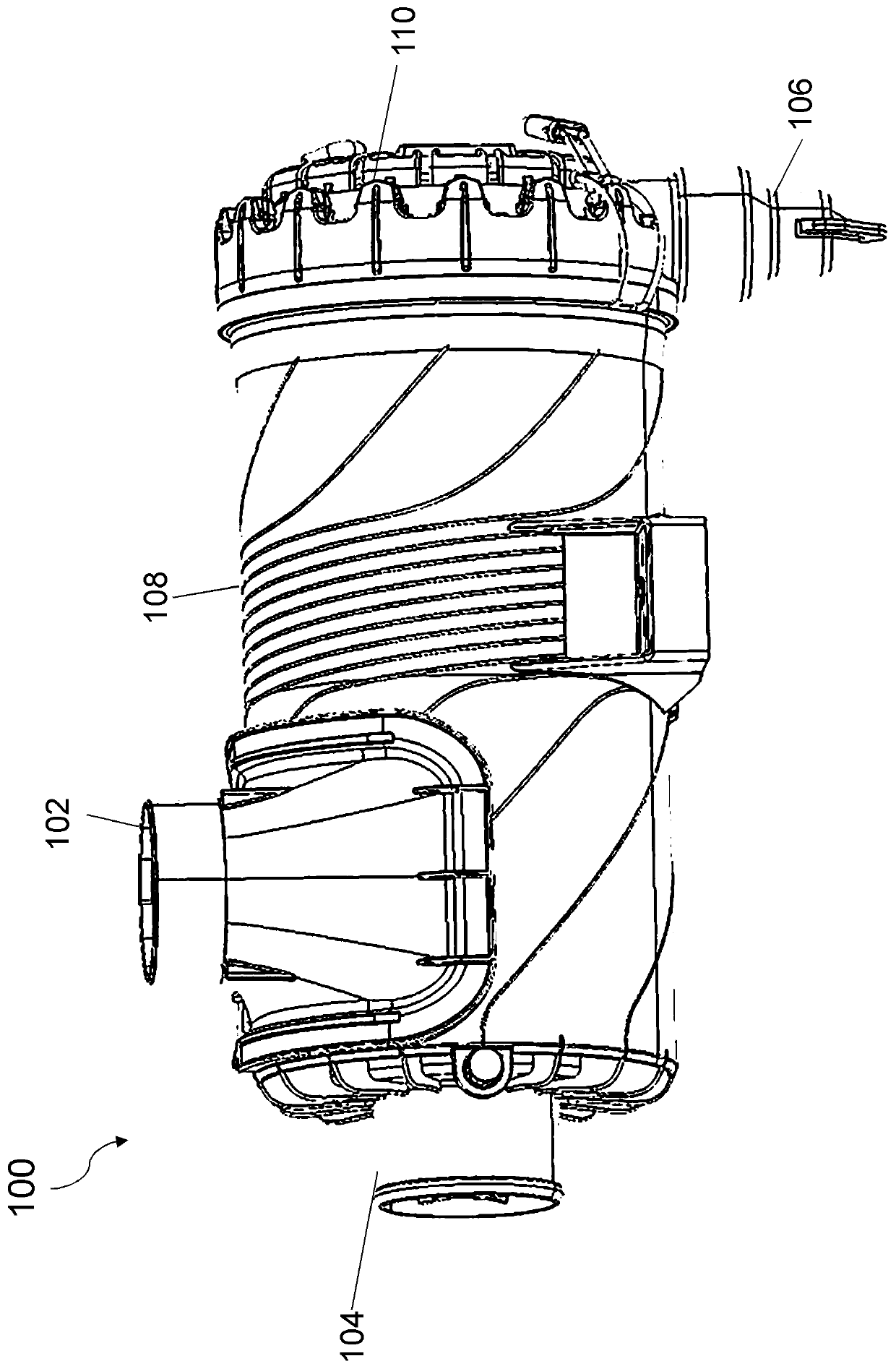

[0040] figure 1 A filter system 100 according to an exemplary embodiment of the invention is shown in a perspective view, which can be used, for example, as an air filter for an internal combustion engine. The filter system 100 has a tangential inlet 102, a central outlet 104 at the end face of the housing, and a dirt outlet 106 at the bottom side of the housing. A circular filter arrangement is shown comprising a housing 108 closed by a cover 110, such as a screw closure or a bayonet coupling closure. When used as an air filter system, dust-laden air flows in through the inlet 102 arranged tangentially to the air filter element arranged in the interior so that due to the inflow protection provided at the filter element The device causes the air in the interior of the housing 108 to swirl. Filter elements and inflow protectors are not shown in the figures. Due to the cyclone effect caused by the rotational movement of the air, centrifugal forces act on the dirt particles en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com