A finished product hanging intelligent assembly line

An assembly line and finished product technology, applied in mechanical conveyors, transportation and packaging, conveyors, etc., can solve the problems of poor system planning, reduce the processing efficiency of hanging assembly lines, etc., to improve processing efficiency, reasonable processing methods, and systematic Strong planning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

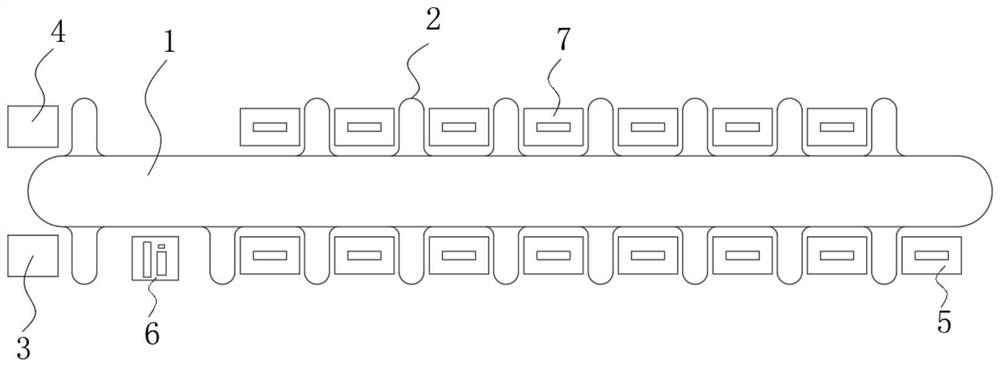

[0026] Such as figure 1 As shown, the embodiment of the present invention provides an intelligent assembly line for hanging finished products, including a circular transmission track 1, a plurality of sub-tracks 2 are arranged on the outer wall of the circular transmission track 1, and a feeding workstation 3 is provided at one end of the circular transmission track 1 With the unloading workstation 4, the other end of the circular transfer track 1 is provided with an inspection workstation 5, and the circular transfer track 1 is provided with a distribution workstation 6 near the loading workstation 3. The two sides of the circular transfer track 1 are located between the inspection workstation 5 and the distribution A plurality of processing workstations 7 are arranged in the middle of the workstation 6, and the processing workstations 7 correspond to the positions of the sub-tracks 2;

[0027] The pipeline consists of the following steps:

[0028] 1) First, refine the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com