A kind of precision stamping cold-rolled steel plate for automobile safety belt buckle and its manufacturing method

A cold-rolled steel plate and precision stamping technology is applied to the cold-rolled steel plate for precision stamping automobile seat belt buckle and its manufacture, and the field of cold-rolled steel plate can solve the problems of being unsuitable for high-speed precision stamping, high hardness and low elongation, etc. Achieve moderate hardness, increase heat treatment hardness, and reduce strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

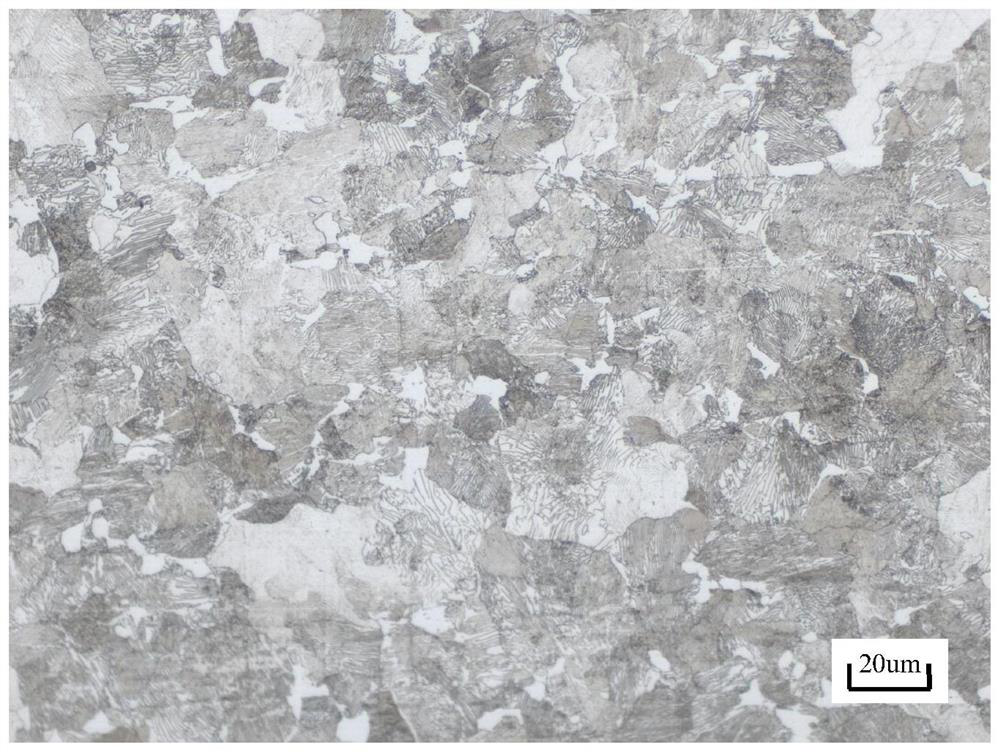

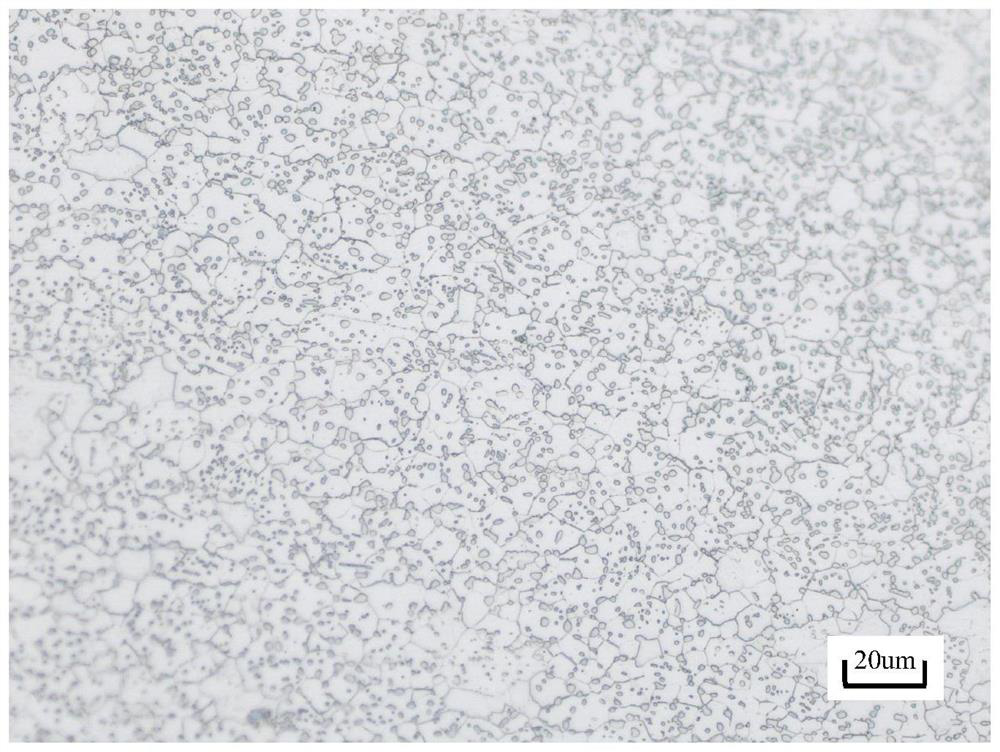

Image

Examples

Embodiment Construction

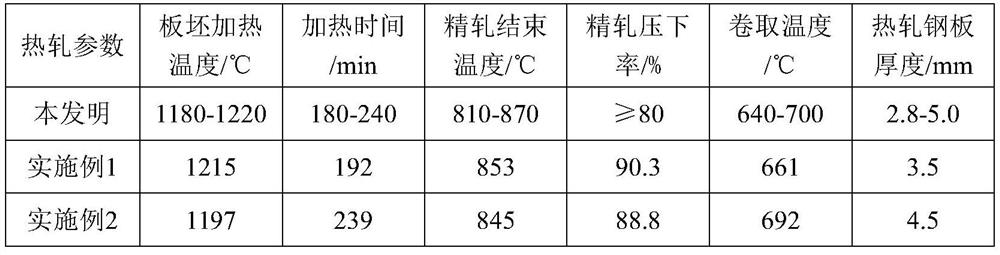

[0043] Below in conjunction with embodiment 1-5 the present invention is further described, as shown in table 1-4.

[0044] Table 1 is the chemical composition (by weight percentage) of the steel of the embodiment of the present invention, and the balance is Fe and unavoidable impurities.

[0045] Table 1 Chemical composition of the steel of the embodiment of the present invention, unit: weight percent.

[0046] element C Si mn P S Cr Al this invention 0.56-0.64 ≤0.2 0.3-0.5 ≤0.015 ≤0.005 0.15-0.25 0.01-0.04 Example 1 0.582 0.176 0.356 0.0135 0.0030 0.19 0.025 Example 2 0.619 0.128 0.375 0.0101 0.0013 0.17 0.017 Example 3 0.603 0.102 0.332 0.0122 0.0019 0.22 0.036 Example 4 0.593 0.132 0.412 0.103 0.0026 0.196 0.023 Example 5 0.613 0.152 0.385 0.116 0.0010 0.179 0.019

[0047] The molten steel that meets the basic requirements of the chemical composition is obtained through converter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com