Correction device for evaporation and correction method

A technology of vapor deposition and locking devices, which is applied in the field of correction devices for vapor deposition, can solve the problems of inconsistency in the uniformity of the inner and outer sides of the laser, and achieve the effect of improving the yield and satisfying the consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

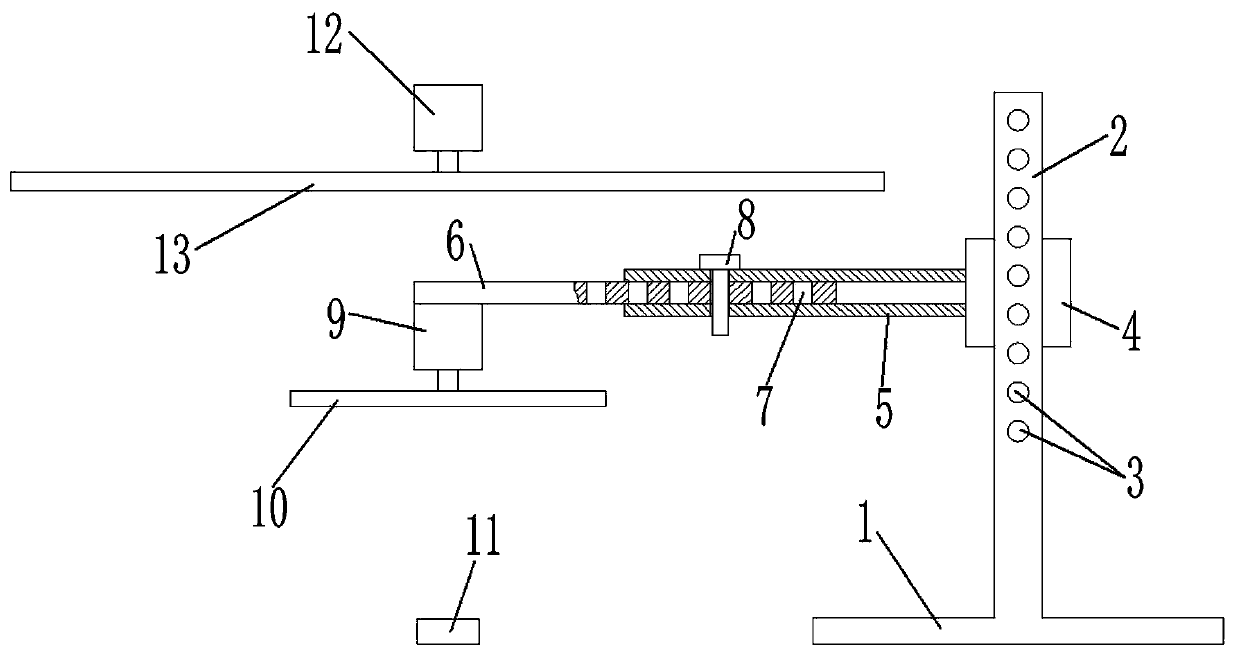

[0033] The locking device I includes a number of sockets I3 arranged at intervals along the axial direction of the column 2 and a positioning hole I arranged on the sleeve 4 to match the socket I3. When an socket I3 is coaxial with the positioning hole I, it can be used The pin shaft I is inserted into the socket I 3 and the positioning hole I. By adjusting the height of the casing 4, when the appropriate height is reached and the jack I 3 coincides coaxially with the positioning hole I, the pin shaft I can be inserted to lock, and the operation is simple.

Embodiment 2

[0035] The above-mentioned locking device II includes a plurality of jacks II 7 arranged at intervals along the axial direction of the cross-branch 6 and a positioning hole II arranged on the cross-branch 5 to match the jacks II 7. When a jack II 7 is the same as the positioning hole II Insert the pin shaft II 8 into the socket II 7 and the positioning hole II behind the shaft. Adjust the position of the horizontal strut 6 horizontally. After the adjustment is in place and the coaxial coincidence of the jack II 7 and the positioning hole II, insert the pin II 8 to lock, and the operation is simple.

Embodiment 3

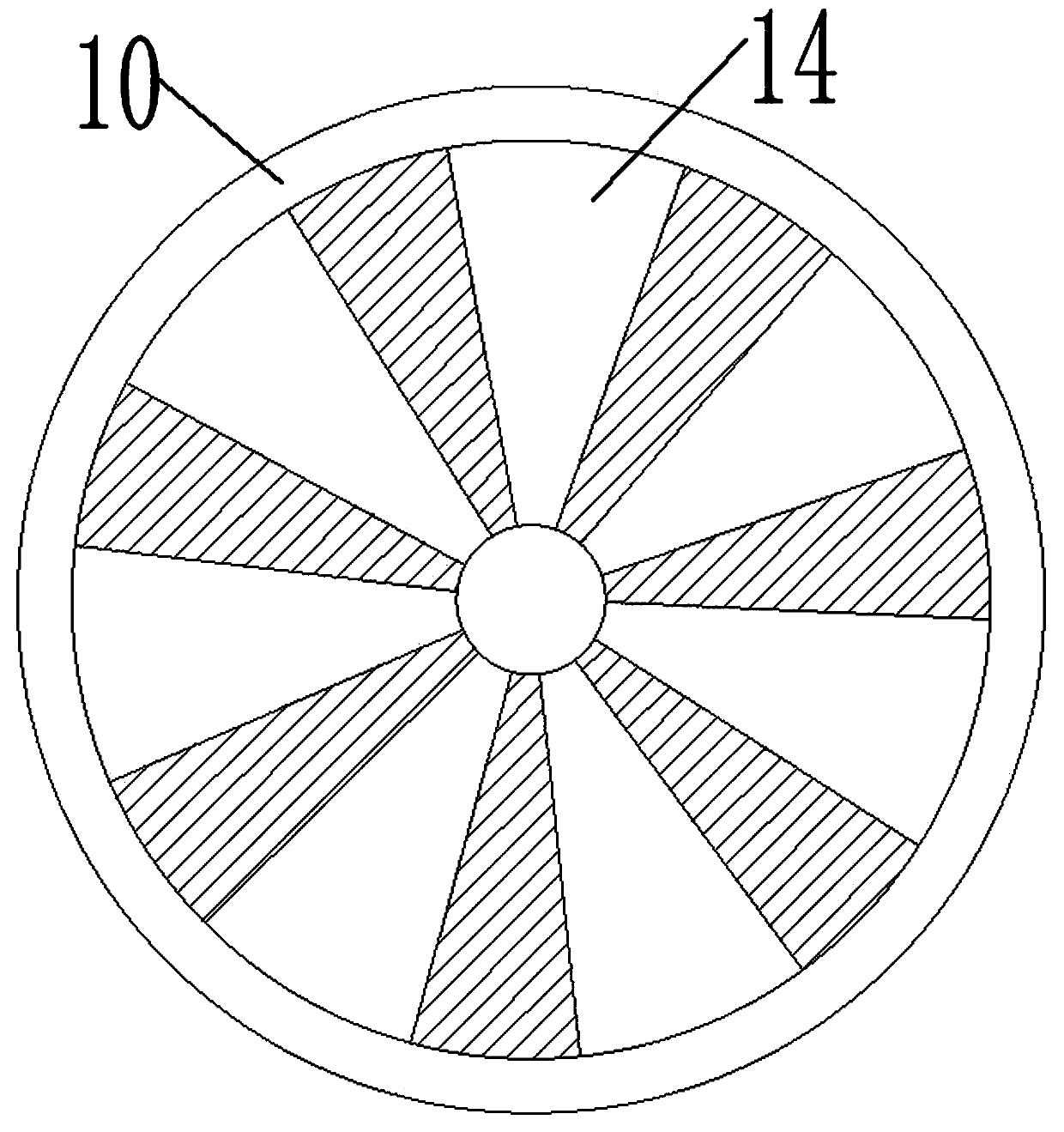

[0037] Preferably, N is a positive integer greater than or equal to 3, and 3 or more correction holes 14 can better guide the evaporated material, further improving the uniformity of evaporation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com