A method for preparing rare earth vanadate thin film by replacement reaction

A technology of rare earth vanadate and replacement reaction, which is applied in the direction of electrolytic inorganic material coating, etc., can solve the problems of affecting the application effect of vanadate and poor substrate adhesion, and achieves high regularity, high adhesion and short time consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] (1) dissolving the gadolinium nitrate compound in deionized water to prepare a rare earth ion solution with a rare earth ion concentration of 1 mol / L to obtain an electrodeposition solution;

[0071] (2) Place the electrodeposition solution prepared in step (1) in a water bath at 5° C., so that the temperature of the electrodeposition solution reaches 5° C. to obtain a standby electrodeposition solution;

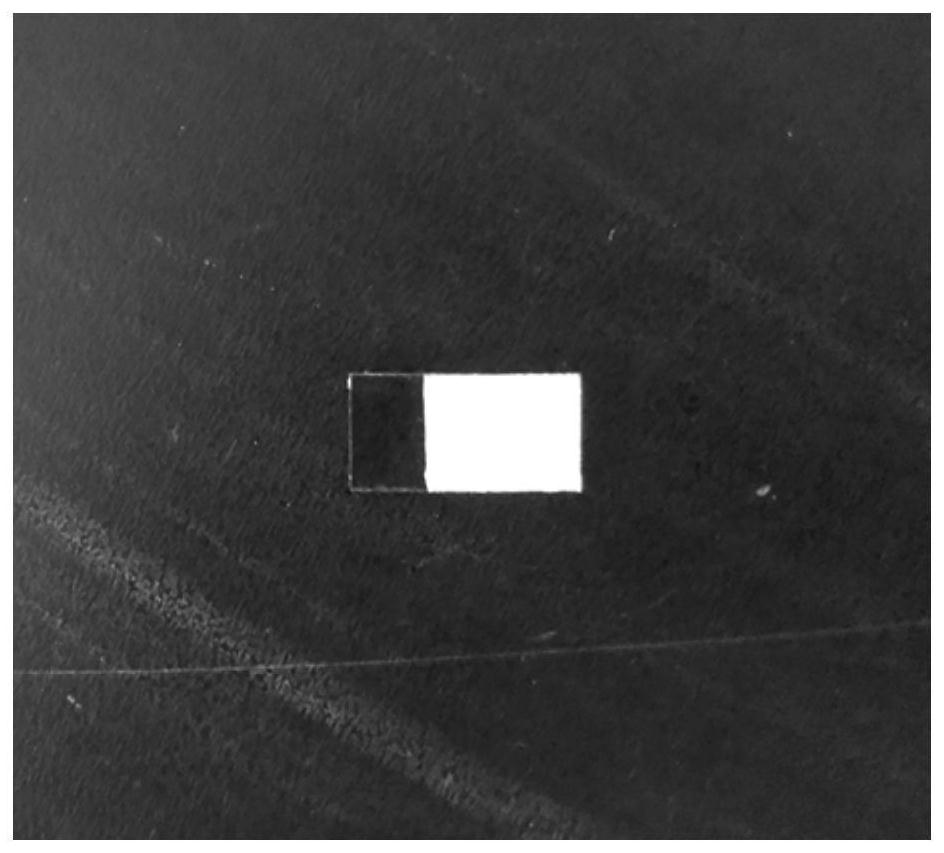

[0072] (3) ITO glass is used as the working electrode, the cathode, and the Pt mesh is used as the counter electrode, the anode. Ag / AgCl / Cl - The electrode is used as a reference electrode to form a three-electrode system;

[0073] (4) Insert the three-electrode system formed in step (3) into the spare electrodeposition solution obtained in step (2), and then use the pulse voltage deposition method, set the deposition voltage to -0.8V, and deposit at this voltage for 1.5min , stop the pressure for 20s, repeat 4 times, then change the voltage to -1V, after depositing ...

Embodiment 2

[0079] (1) dissolving terbium nitrate in deionized water to prepare a rare earth ion solution with a rare earth ion concentration of 0.05mol / L to obtain an electrodeposition solution;

[0080] (2) Place the electrodeposition solution prepared in step (1) in a water bath at 20° C., so that the temperature of the electrodeposition solution reaches 20° C. to obtain a standby electrodeposition solution;

[0081] (3) The sheet material of ITO glass is used as the working electrode, that is, the cathode, and the Pt mesh is used as the counter electrode, that is, the anode, and Ag / AgCl / Cl - The electrode is used as a reference electrode to form a three-electrode system;

[0082](4) Insert the three-electrode system formed in step (3) into the standby electrodeposition solution obtained in step (2), and then use the pulse voltage deposition method, set the deposition voltage to -1.1V, and deposit at this voltage for 1 min. Stop the pressure for 30s, repeat it twice, then change the v...

Embodiment 3

[0088] (1) dissolving the yttrium nitrate compound in deionized water to prepare a rare earth ion solution with a rare earth ion concentration of 0.01mol / L to obtain an electrodeposition solution;

[0089] (2) placing the electrodeposition solution prepared in step (1) in a water bath, so that the temperature of the electrodeposition solution reaches 80° C. to obtain a standby electrodeposition solution;

[0090] (3) The sheet material of ITO glass is used as the working electrode, that is, the cathode, and the Pt mesh is used as the counter electrode, that is, the anode, and Ag / AgCl / Cl - The electrode is used as a reference electrode to form a three-electrode system;

[0091] (4) Insert the three-electrode system formed in step (3) into the standby electrodeposition solution obtained in step (2), and then use the pulse voltage deposition method, set the deposition voltage to -1.15V, and deposit at this voltage for 12 minutes, Stop the pressure for 60s, repeat 5 times, then c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com