Mineral wool board with photocatalyst coating

A photocatalyst, mineral wool board technology, applied in covering/lining, building, building structure, etc., can solve problems such as single performance, achieve the effect of improving comprehensive performance, improving connection stability, and overcoming single performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

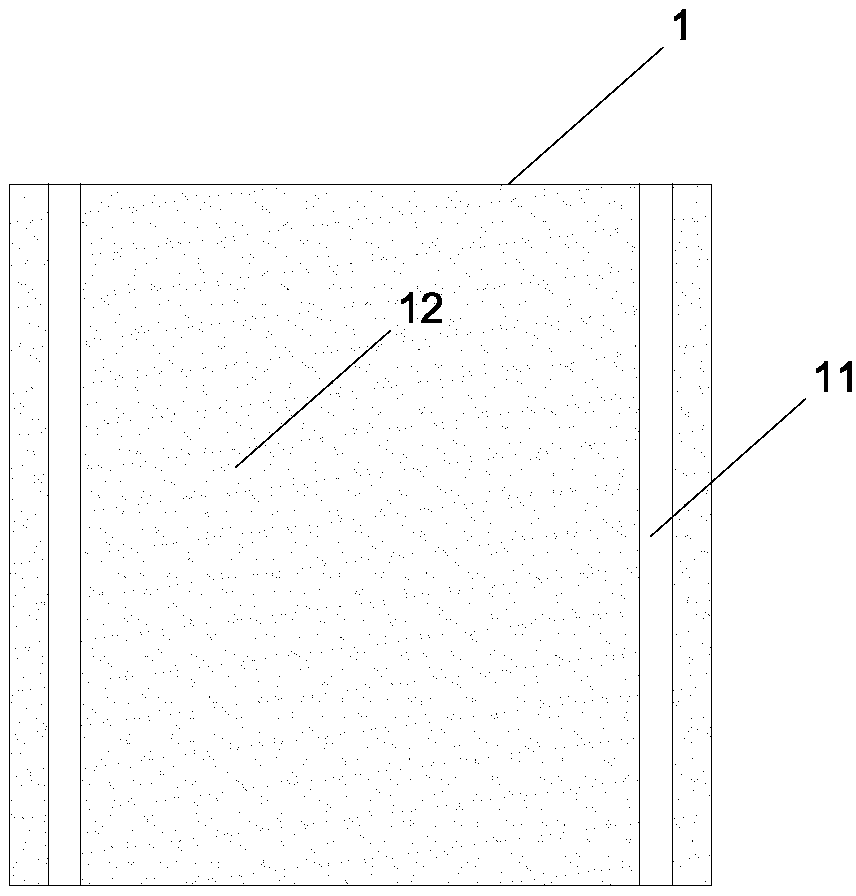

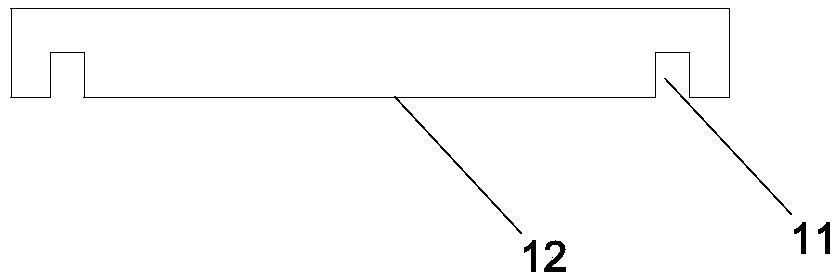

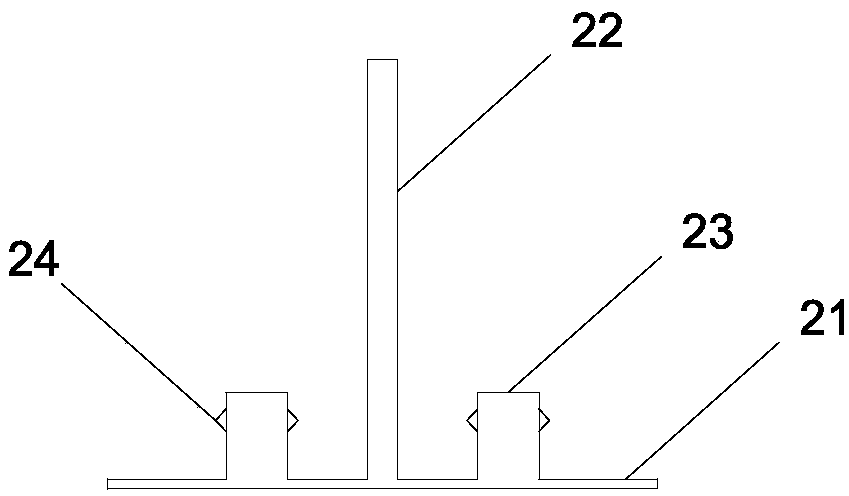

[0036] combine figure 1 , figure 2 As shown, Embodiment 1 of the present invention provides a mineral wool board with a photocatalyst coating, the decorative surface 12 of the mineral wool board 1 is provided with a photocatalyst coating, and the photocatalyst coating includes nitrogen-doped titanium dioxide.

[0037] In the specific operation, the nitrogen-doped titanium dioxide photocatalytic coating can be used to degrade indoor formaldehyde and inhibit the reproduction of mold, so as to realize the purification operation of indoor air; the above-mentioned photocatalyst coating can effectively improve the air purification performance of the mineral wool board 1 The above-mentioned photocatalyst coating can be evenly sprayed on the decorative surface 12 of the mineral wool board 1, and the decorative surface 12 of the mineral wool board 1 is set downwards, which can purify the air in the space where people move, and can effectively improve the comfort of the room.

[0038]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com