Anti-permeation mineral wool board

A mineral wool board and anti-seepage technology, applied in building components, building materials, buildings, etc., can solve problems such as single performance, achieve the effects of improving overall performance, improving connection stability, and overcoming single performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

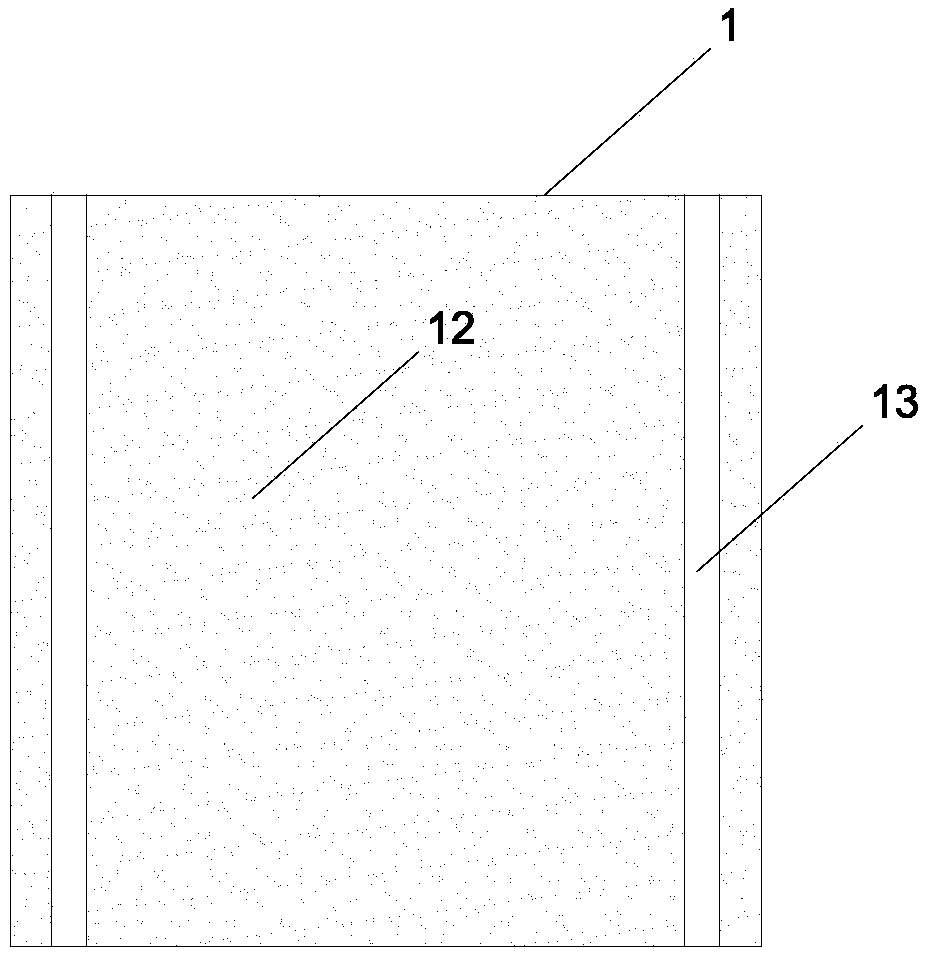

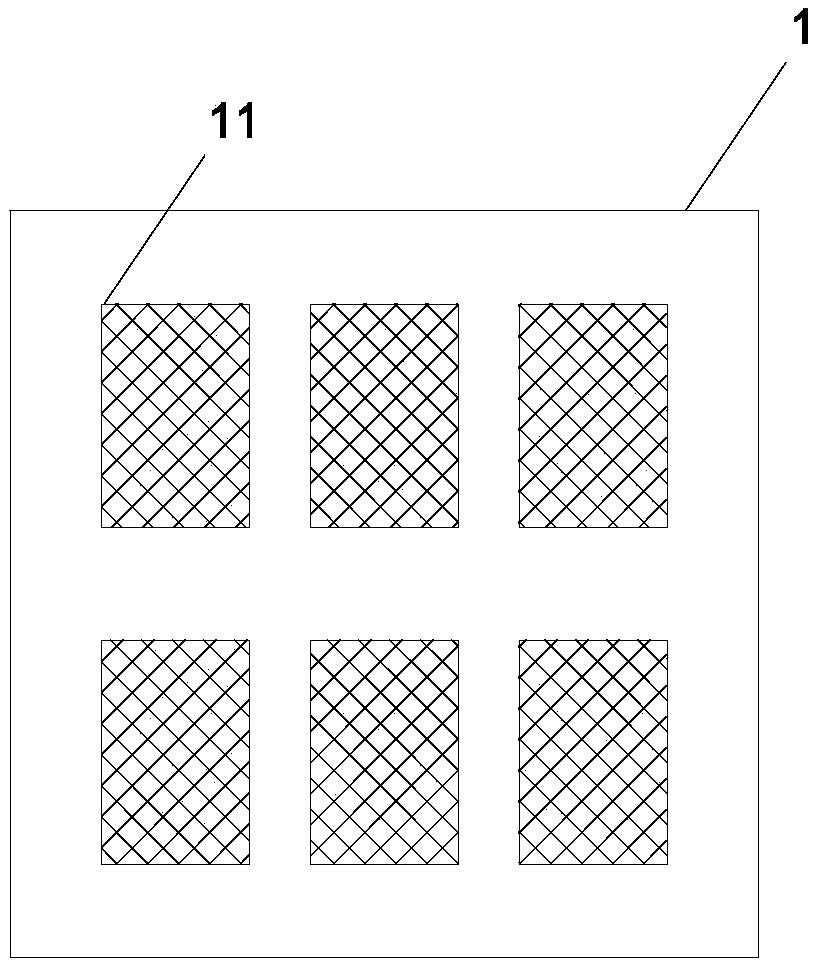

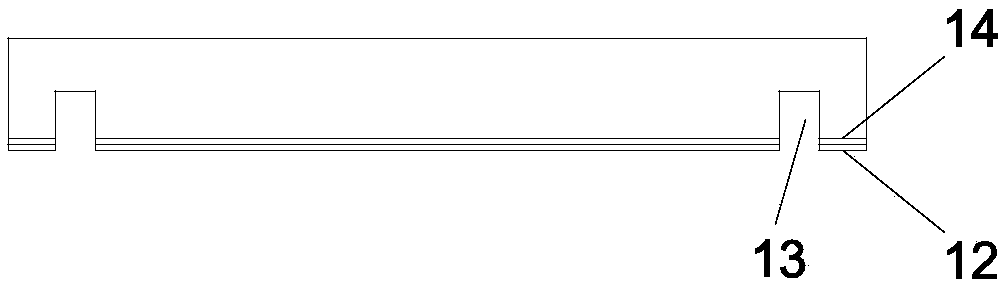

[0039] combine figure 1 , figure 2 As shown, embodiment one of the present invention provides a kind of impervious mineral wool board, the front of mineral wool board 1 is decorative surface, and the decorative surface of mineral wool board 1 is provided with photocatalyst coating 12, and the decorative surface and photocatalyst coating 12 An impermeable layer 14 is arranged between them, and the photocatalyst coating 12 includes nitrogen-doped titanium dioxide; it should be noted that the front of the mineral wool board 1 is the surface of the mineral wool board 1 facing the indoor space in the ceiling system; the mineral wool board 1 The back side is the surface of the mineral wool board 1 facing the roof in the ceiling system.

[0040] In the specific operation, the nitrogen-doped titanium dioxide photocatalytic coating can be used to degrade indoor formaldehyde and inhibit the reproduction of mold, so as to realize the purification operation of indoor air; the setting of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com