Variable capacity compressor

A compressor, variable technology, applied in the direction of liquid variable capacity machinery, mechanical equipment, machine/engine, etc., can solve problems such as excessive protrusions, reduced compressor efficiency, complex external shape, etc., to achieve improved durability, The effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. Prior to this, the terms or words used in this specification and claims should not be construed as limited to ordinary or dictionary meanings, but to best illustrate the concept of the present invention according to the concept that the inventor can properly define the terms In principle, the concepts of the corresponding terms must be interpreted as meanings and concepts consistent with the technical ideas of the present invention.

[0040] Therefore, the embodiments described in this specification and the structures shown in the drawings are only the most preferred embodiments of the present invention, and do not represent all technical ideas of the present invention. Therefore, it should be understood that the present application may have alternative equivalent modification of .

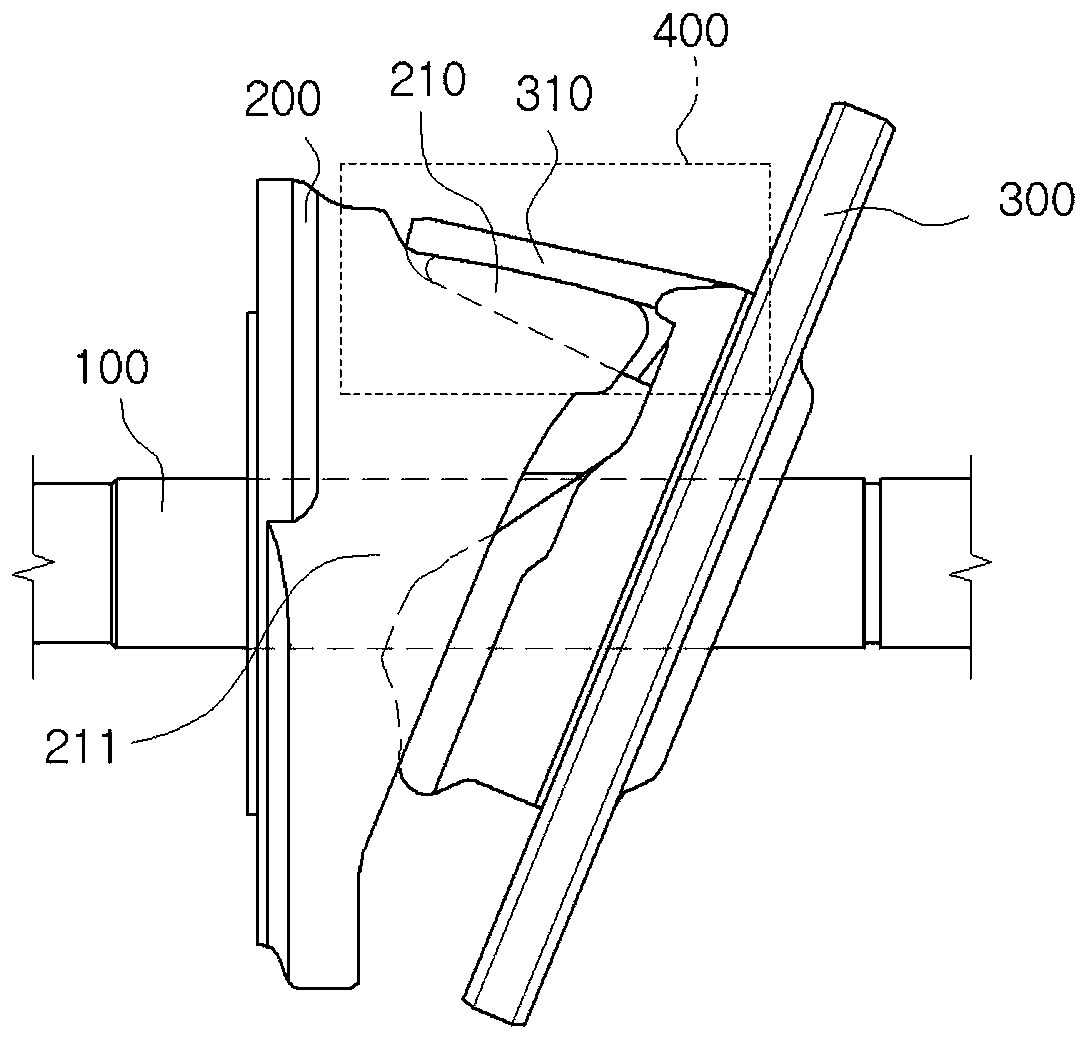

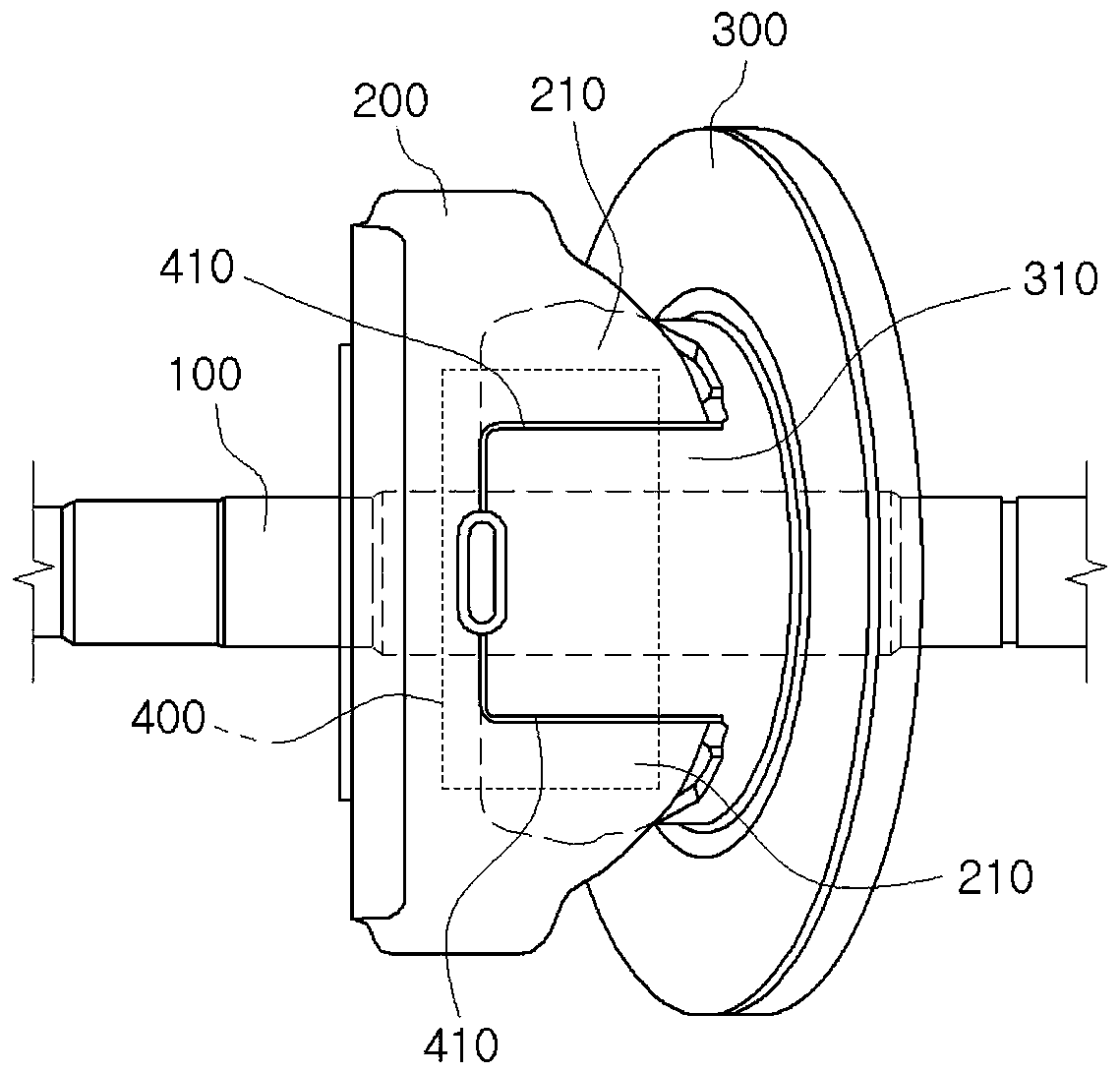

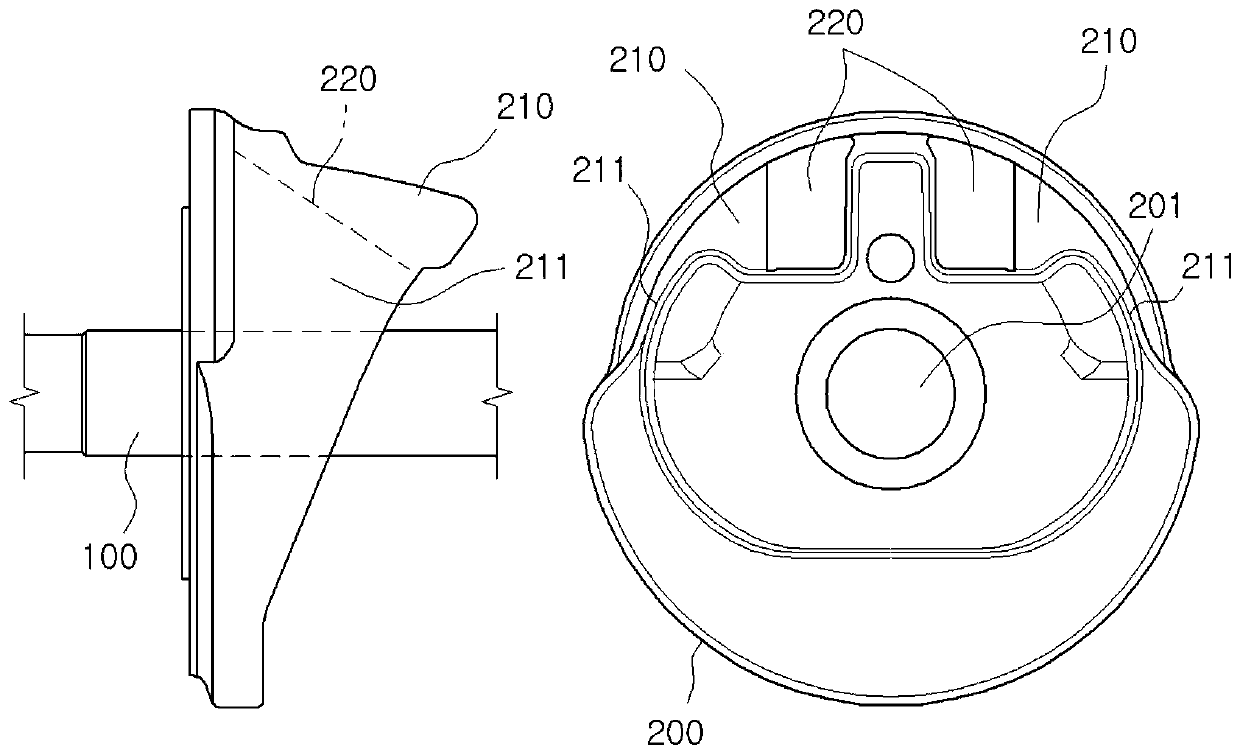

[0041] The present invention relates to a variable disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com