Dragging experiment table for small light-load motor

A light-load, test bench technology, applied in the field of drag test benches, can solve problems such as weak protection, no protective structure, and large safety hazards, and achieve the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

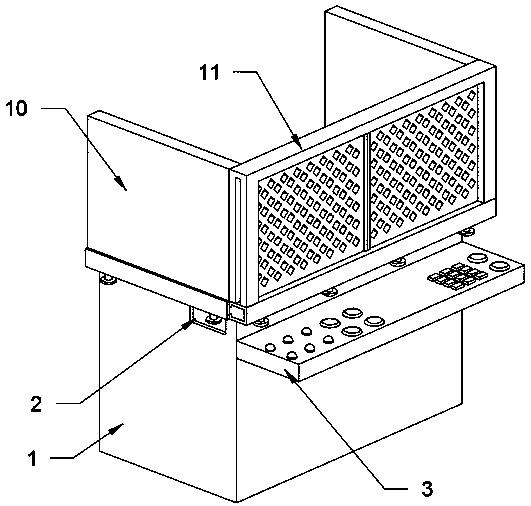

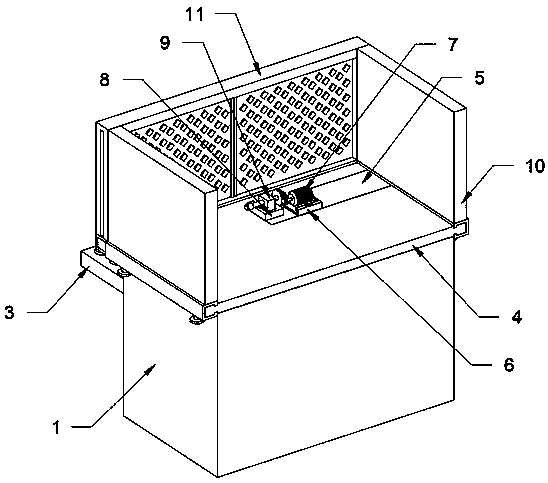

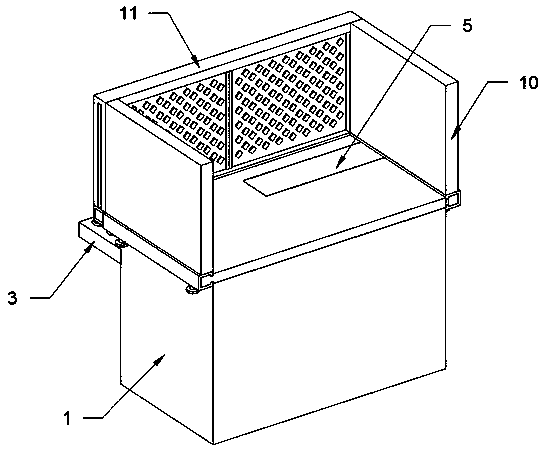

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The invention provides a drag test bench for small light-load motors, including a cabinet body 1, a rectangular hole 2, a console 3, a test bench table 4, a sliding groove 401, a card slot A402, a card slot B403, and a fixed plate for an experiment body 5. Card slot C501, motor fixing seat 6, sliding seat A601, sliding block A602, motor 7, gear A701, test structure fixing seat 8, sliding seat B801, sliding block B802, test structure 9, gear B901, gear C902, gear D903, side protection plate 10, main protection plate 11, frame 1101, door panel 1102 and rectangular magnet 1103; the cabinet body 1 is a rectangular cabinet-shaped struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com