Wide cage structure for poultry farming

A poultry, wide-body technology, applied in poultry cages or houses, applications, poultry industry, etc., can solve problems such as the tipping of fixed support parts, achieve resistance to deformation force, improve the ability to resist deflection force, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

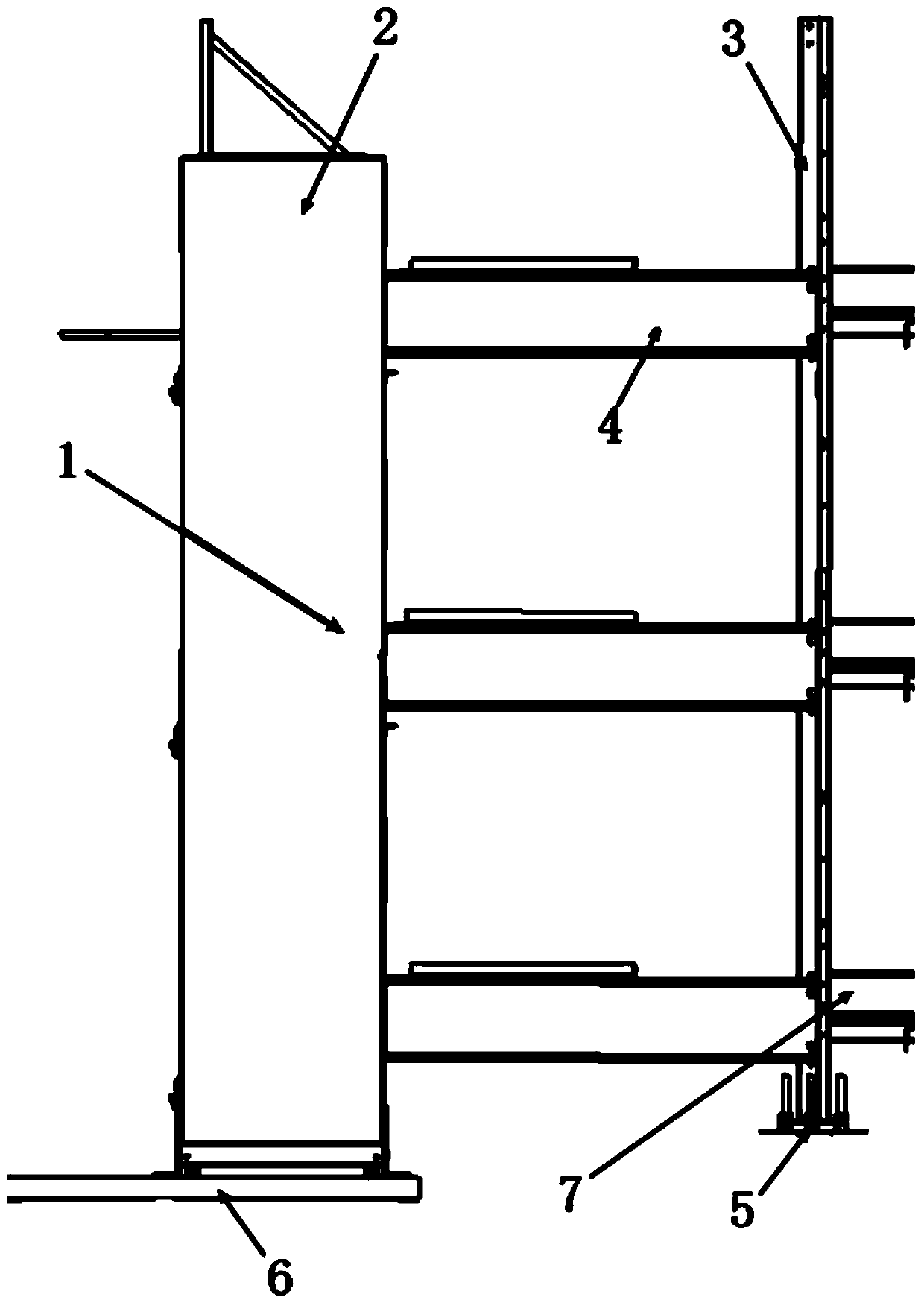

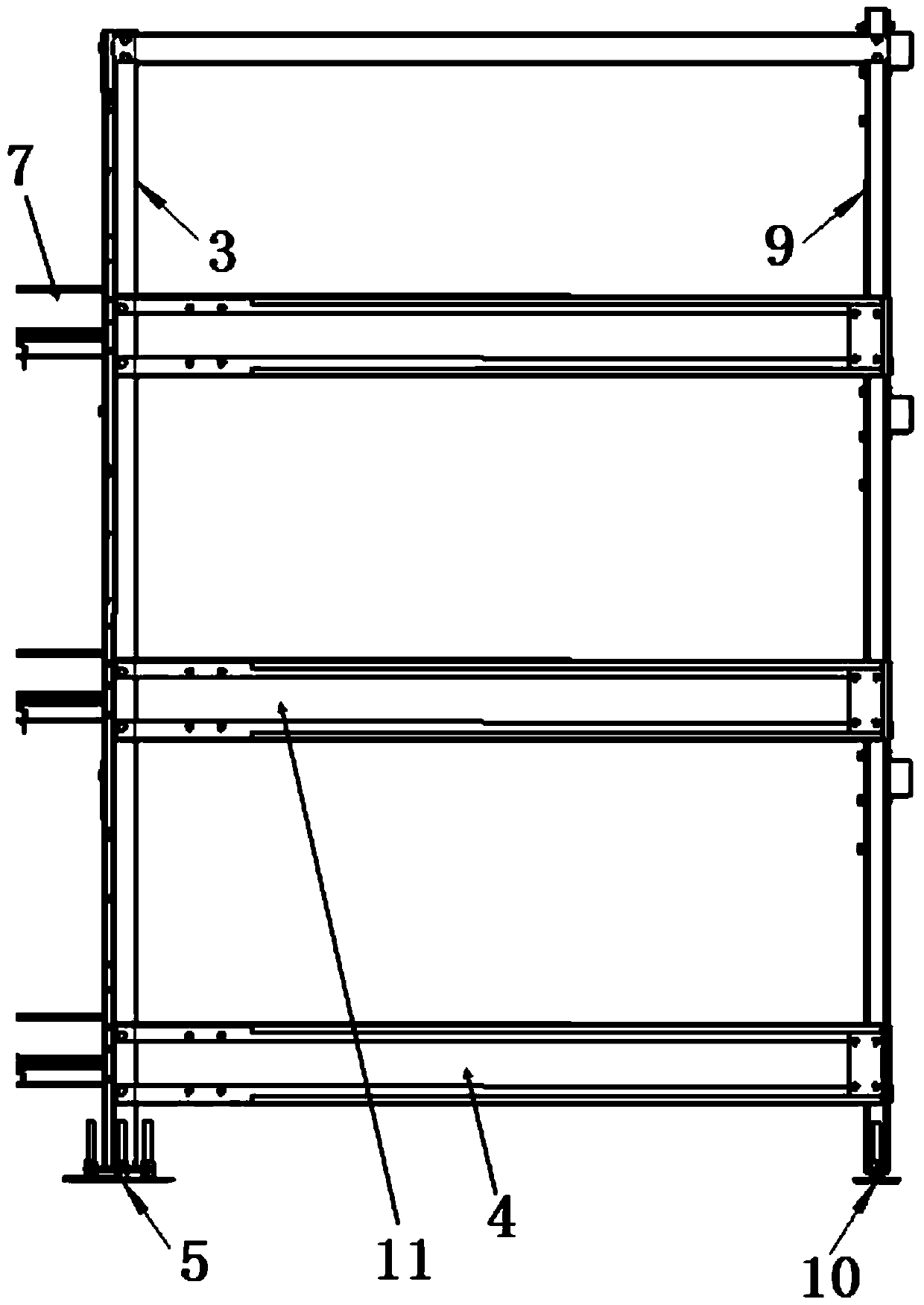

[0034] In a typical implementation of the present application, such as Figure 1-Figure 5 As shown, a wide-body cage structure for poultry breeding is proposed.

[0035] Its main body is a cage body 7, and the volume of described cage body is determined according to the scale of required cultivation, and overall appearance is shown as a cube, and the cube is placed horizontally, and the four edges in the vertical direction are equipped with reinforcing columns 3 respectively, and the top of the column is strengthened. It is flush with the top surface of the cage body, and the bottom end is lower than the bottom surface of the cage body, which is used to contact the ground to support the entire cage body, so that the cage body is suspended in the air as a whole; in this embodiment, the cage body has a multi-layer structure, and the adjacent layers There is a gap between them, which is used to receive the excrement discharged from the poultry raised in the upper cage.

[0036]F...

Embodiment 2

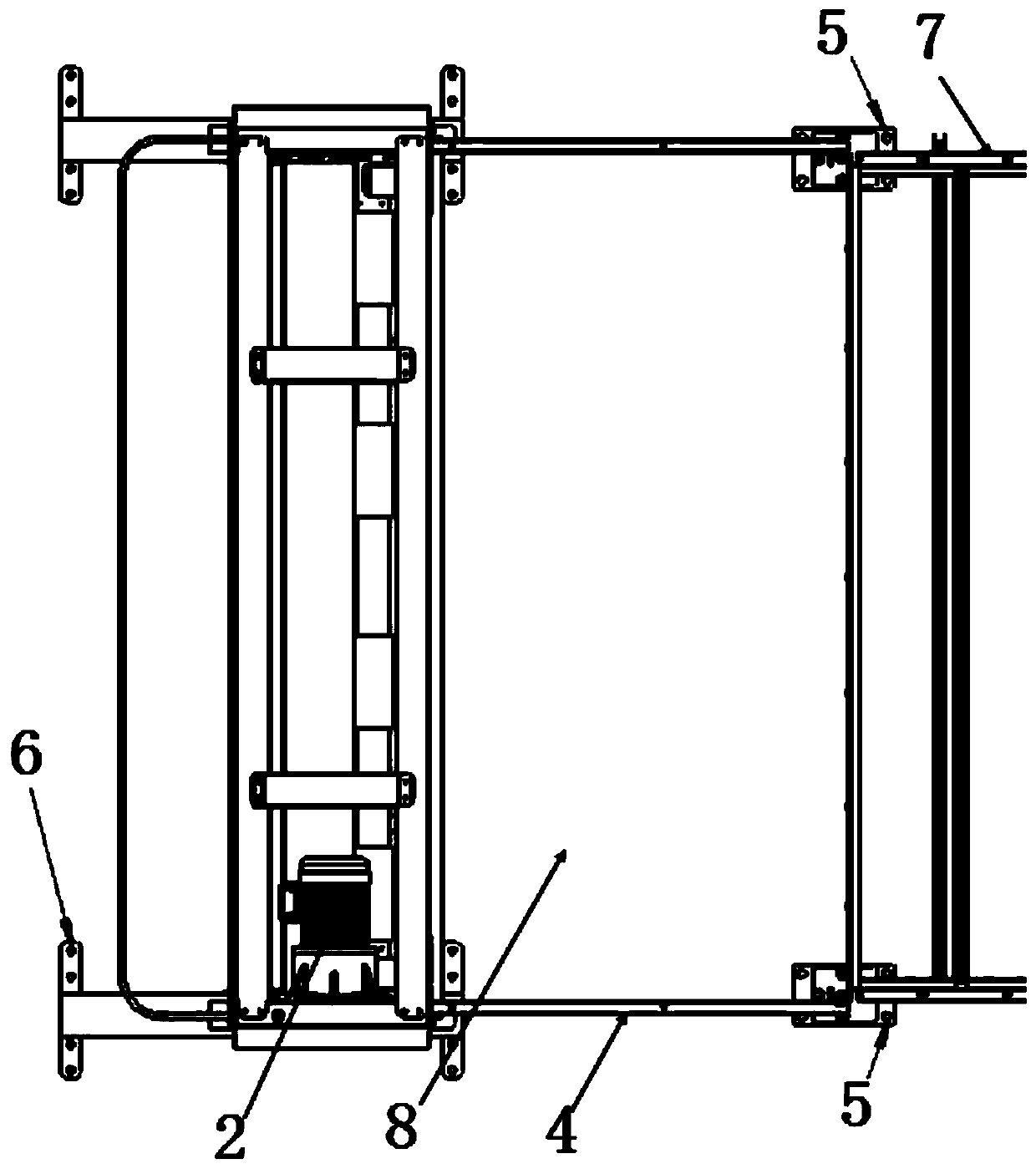

[0050] In another typical embodiment of the present application, another wide-body cage structure for poultry breeding is provided. The difference from Embodiment 1 is that the driving roller is driven by a motor to drive the operation of the conveyor belt.

[0051] The main structure of the first bracket and the second bracket is the same, and they are respectively installed at the two ends of the cage body. The driving roller is installed on the first bracket, and the driving roller is equipped with a motor, and the motor drives the driving roller to rotate; it is related to the structure and implementation Example 1 is the same.

[0052] Both the first bracket and the second bracket are fixed on the ground. Due to the lack of traction by the large weight of the main drive as in Embodiment 1, the first bracket also needs to be fixed on the ground to improve its tensile capacity.

[0053] Compared with setting the first bracket and the second bracket separated from the cage b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com