Catalyst for preparing acrylic acid or acrolein and its preparation method

A catalyst and acrolein technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low selectivity of target products, serious carbon deposition in equipment, high content of by-products, etc., and achieve excellent results Anti-carbon performance, improved service life, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

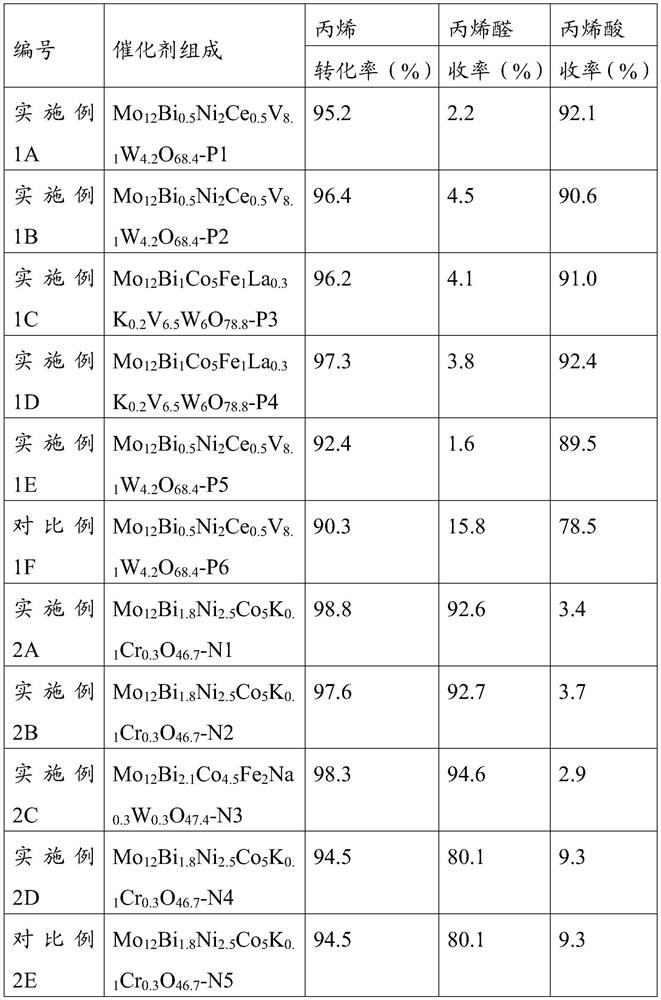

Examples

Embodiment 1A

[0074] First, 135.8g ammonium molybdate, 37.2g cobalt nitrate and 13.9g cerium nitrate were dissolved in 500mL distilled water, and fully stirred and dissolved under the action of a high-shear stirrer to obtain solution A; secondly, 66.6g ammonium metatungstate and 60.6g Ammonium metavanadate was dissolved in 230mL of distilled water to form solution B, and under the action of a peristaltic pump, solution B was slowly added dropwise to solution A to form material I; subsequently, 15.5g of bismuth nitrate was dissolved in 60mL with a volume fraction of 13 % dilute nitric acid solution to form solution C, and solution C is added dropwise to material I according to the dripping method of solution B. At the same time, 100g tetraphenylphosphorous chloride and 40g palmitic acid are added to material I to form material II. After being fully stirred and mixed, the obtained material is spray-dried. Specifically, the spray-drying conditions were set as the inlet air temperature was 200°...

Embodiment 1B

[0078] The preparation of the catalyst active component is basically the same as in Example 1-1, except that the phosphorus-containing ion additive is replaced by 68 g of tetramethylphosphorus bromide from 100 g of tetraphenylphosphorous chloride. The prepared catalyst is P2, and its molecular formula is Mo 12 Bi 0.5 Ni 2 Ce 0.5 V 8.1 W 4.2 o 68.4 .

[0079] The selection of the catalyst carrier powder and the catalyst molding method are also basically the same as those in Example 1-1.

[0080] Similarly, the catalyst evaluation is basically the same as in Example 1-1. Weigh 45g of the molded catalyst sample and fill it in a fixed-bed reactor, and perform performance evaluation according to the evaluation conditions of the above-mentioned acrylic acid catalyst. The evaluation results show that the conversion of propylene The yield of acrylic acid was 96.4%, the yield of acrylic acid was 90.6%, and the yield of acrolein was 4.5%. The 500h life test of the catalyst found ...

Embodiment 1C

[0082] Dissolve 148.6g ammonium molybdate, 102.3g cobalt nitrate, 28.3g iron nitrate, 1.4g potassium nitrate and 9.1g lanthanum nitrate in 500mL distilled water to form solution A; secondly, weigh 53.2g ammonium metavanadate and 104.1g Ammonium dodecametatungstate was dissolved in 250mL of distilled water, and fully dissolved to form solution B, then under the action of a peristaltic pump, according to the dropping rate of 36mL / h and under the action of a high-shear stirrer, it was added dropwise to Suspension I was formed in solution A; then, 34.3g of bismuth nitrate was weighed and dissolved in 120mL of dilute nitric acid solution with a volume fraction of 13% to form solution C, and solution C was slowly added dropwise to the above-mentioned In the I suspension, at the same time, 400mL ethanol solution formed by 150g tetrabutylphosphorus bromide and 44g polyvinyl alcohol was added in the suspension I according to the same adding method, after the rapid stirring of the high-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com