Support device for base reinforcement welding

A technology for supporting devices and steel bars, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to guarantee the vertical level of steel bars, high labor intensity, and small labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

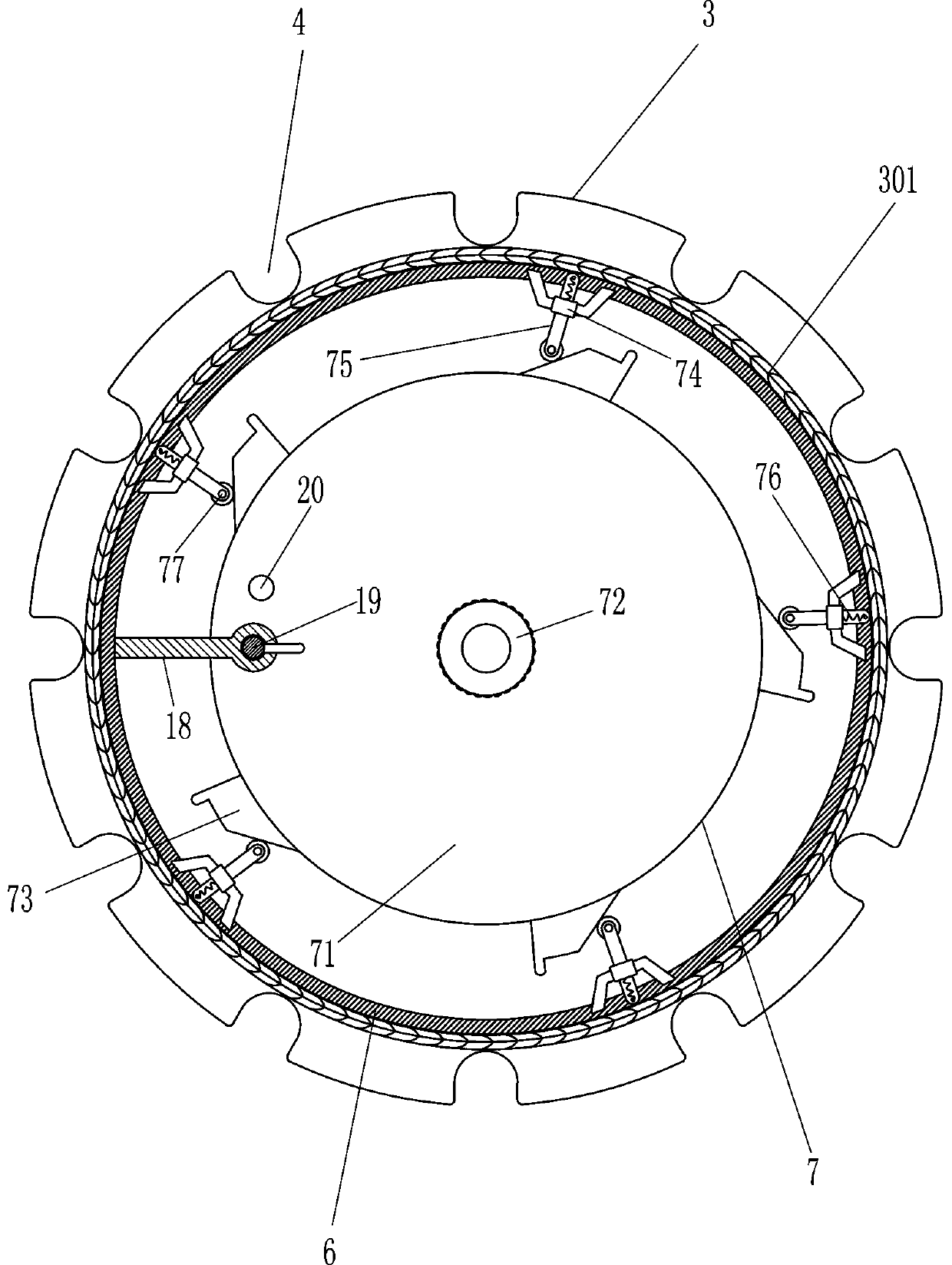

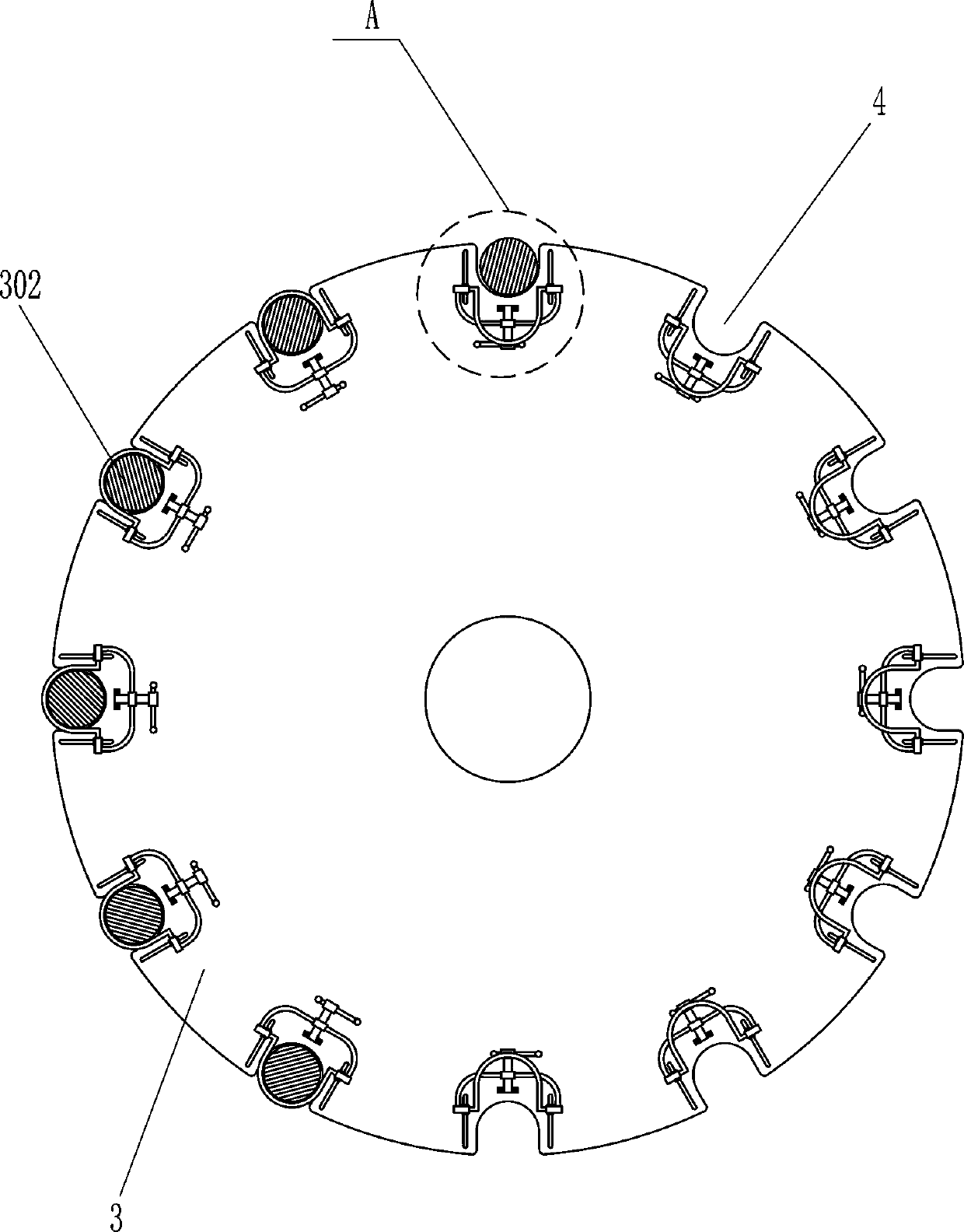

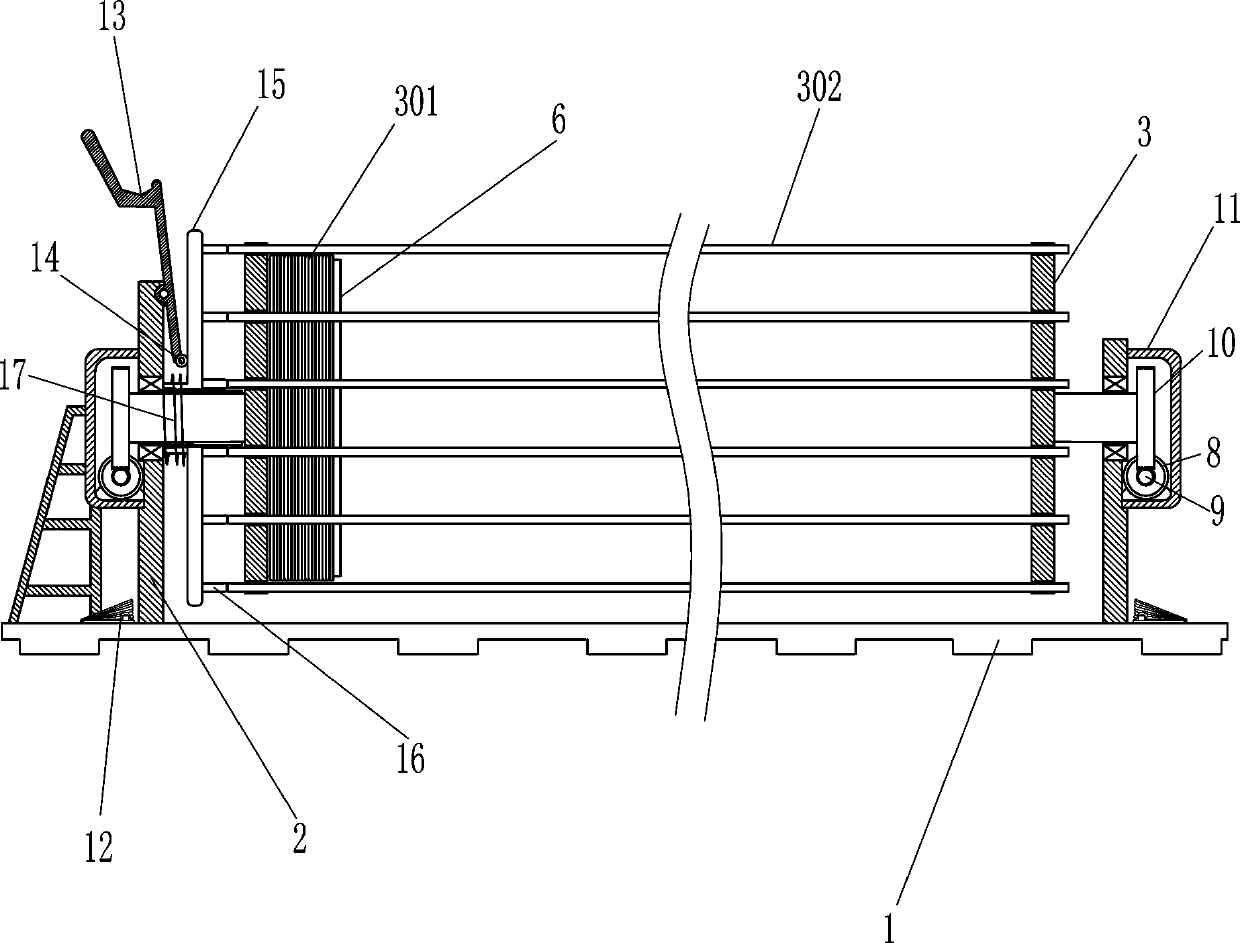

[0021] see Figure 1-Figure 3 , the application provides a supporting device for welding steel bars in foundation construction, including a base 1, a fixed plate 2 and a first disc 3, the left and right sides of the top of the base 1 are provided with fixed plates 2, and the fixed plates 2 are connected by welding The method is connected with the base 1, and the fixed plate 2 is equipped with a first disc 3 which is rotated, and the first disc 3 is provided with a connecting shaft, and the first disc 3 is rotated through the connecting shaft of the bearing seat and the fixed plate 2. Connected, the outer sides of the first disk 3 on the left and right sides are evenly provided with grooves 4 at circumferential intervals, the shape of the groove 4 is U-shaped, and a hollow tube 6 and a fixing device 5 are also included. The first disk 3 on the left The inner surface of the inner surface is provided with a hollow tube 6, and the hollow tube 6 is connected with the first disc 3 b...

no. 2 approach

[0026] see Figure 4 , also includes a limit mechanism 7, the limit mechanism 7 includes a turntable 71, a handle 72, a wedge 73, a guide sleeve 74, a bar 75, an elastic cord and a first contact wheel 77, the first disc 3 on the left side The upper rotation type is provided with a turntable 71, the turntable 71 is connected to the first disc 3 by means of a rotating shaft connection, the turntable 71 is provided with a turning handle 72, and the turning handle 72 is welded at the center of the right side of the turntable 71, and the outer side of the turntable 71 Five wedge-shaped blocks 73 are evenly distributed, and five guide sleeves 74 are evenly distributed on the right end of the hollow tube 6. The guide sleeve 74 is slidingly provided with a retaining rod 75, and an elastic rope is connected between the retaining rod 75 and the guide sleeve 74, and the retaining rod 75 is rotatably provided with a first contact wheel 77 near one end of the turntable 71 , and the first c...

no. 3 approach

[0029] see figure 1 and Figure 5 , also includes motor 8, worm screw 9, worm gear 10, housing 11 and foot switch 12, housing 11 is provided on the fixed plate 2 on the left and right sides, motor 8 is installed in the housing 11, on the output shaft of motor 8 A worm 9 is provided, and the worm 9 is parallel to the base 1. A worm wheel 10 is provided at the axis of the first disk 3. The worm wheel 10 is connected to the connecting shaft of the first disk 3 through an interference connection. The worm wheel 10 and The worm 9 is meshed, the worm wheel 10 and the worm 9 are all located in the housing 11, the left and right sides of the top of the base 1 are provided with foot switches 12, and the foot switches 12 are fixed on the base by means of bolt connections, and the foot switches 12 are connected to the motor. 8 are electrically connected.

[0030] When it is necessary to rotate the first disk 3 to replace the position of the groove 4, two people step on the left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com