Precise synthesis device for high-precision high-elasticity micro-ultrathin metal thin film

A technology of ultra-thin metal and synthesis device, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of product quality control, slow production efficiency, inconsistent strength, etc., to improve product qualification rate and ensure horizontal stability , Stable consistency and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

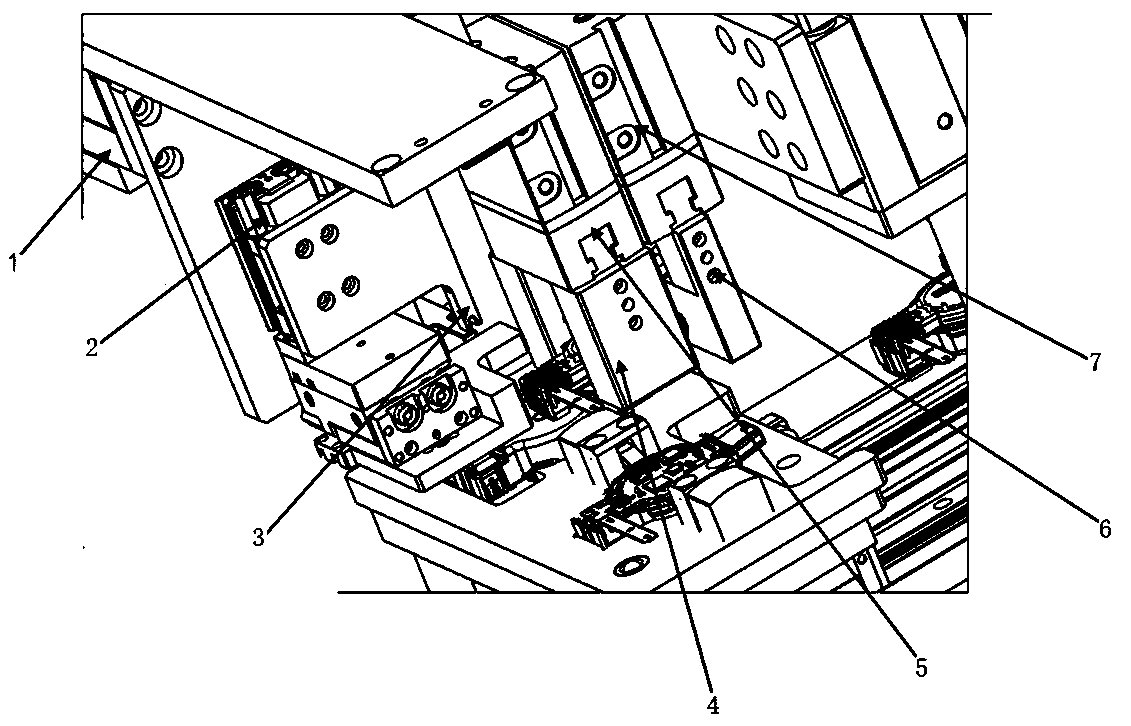

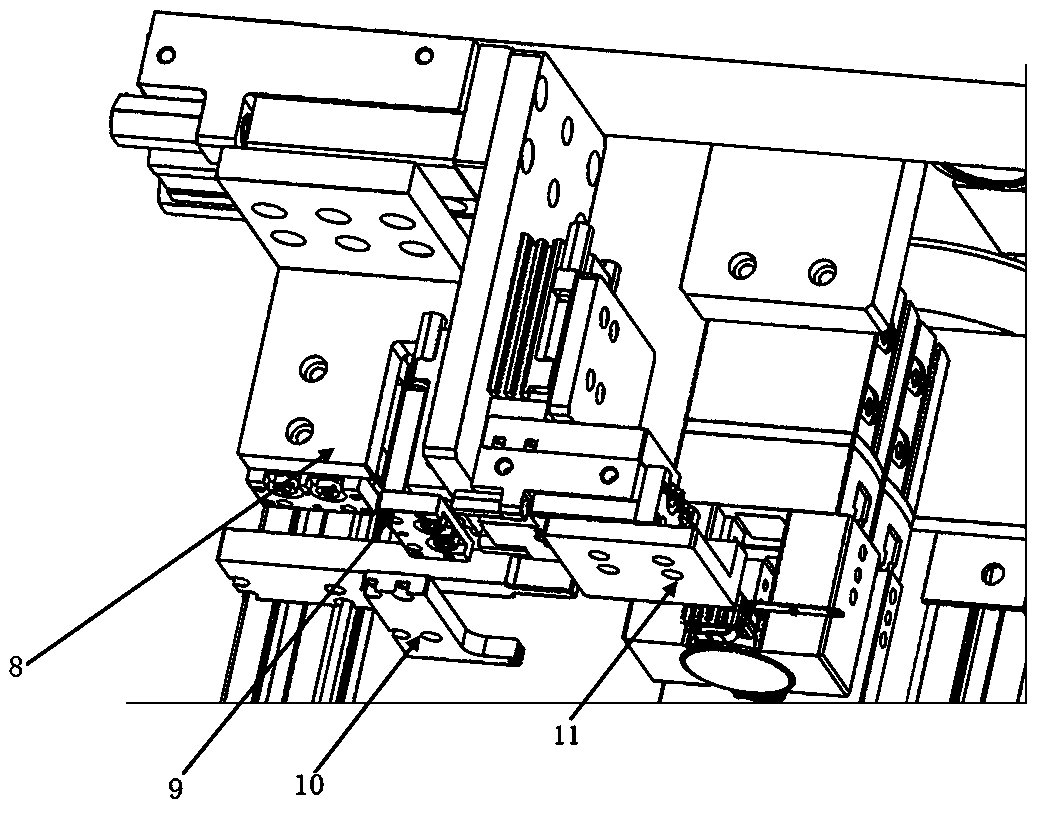

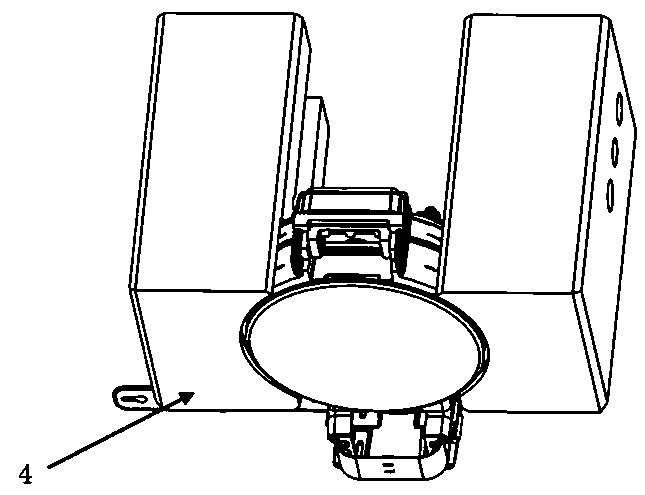

[0016] Example: such as figure 1 As shown, in the present embodiment, the high-precision and high-elastic micro-ultra-thin metal film precision synthesis device includes a first product profiling gripper 1 and a second product profiling gripper 6, and these two profiling grippers are used for The product is clamped. combine image 3 with Figure 4 As shown, the first product profiling gripper 1 and the second product profiling gripper 6 are respectively provided with grooves matching the shape and size of the outer contour of the product. Clamping, avoid clamping the position where the film needs to be wrapped when clamping, as long as the position is always exposed.

[0017] In the specific implementation process: the product is first placed on the reference base, and the upper and lower protective covers of the product are removed, waiting for winding. Through the profiling gripper 4 of the first product and the profiling gripper 6 of the second product, the product is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com