Composite material small pit forming and pressurizing device and pressurizing method

A composite material and pressurizing device technology, applied in the field of process equipment, can solve problems such as difficulty in pressurization, crispness, etc., and achieve the effects of improving the balance of pressurization and the dimensional accuracy of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

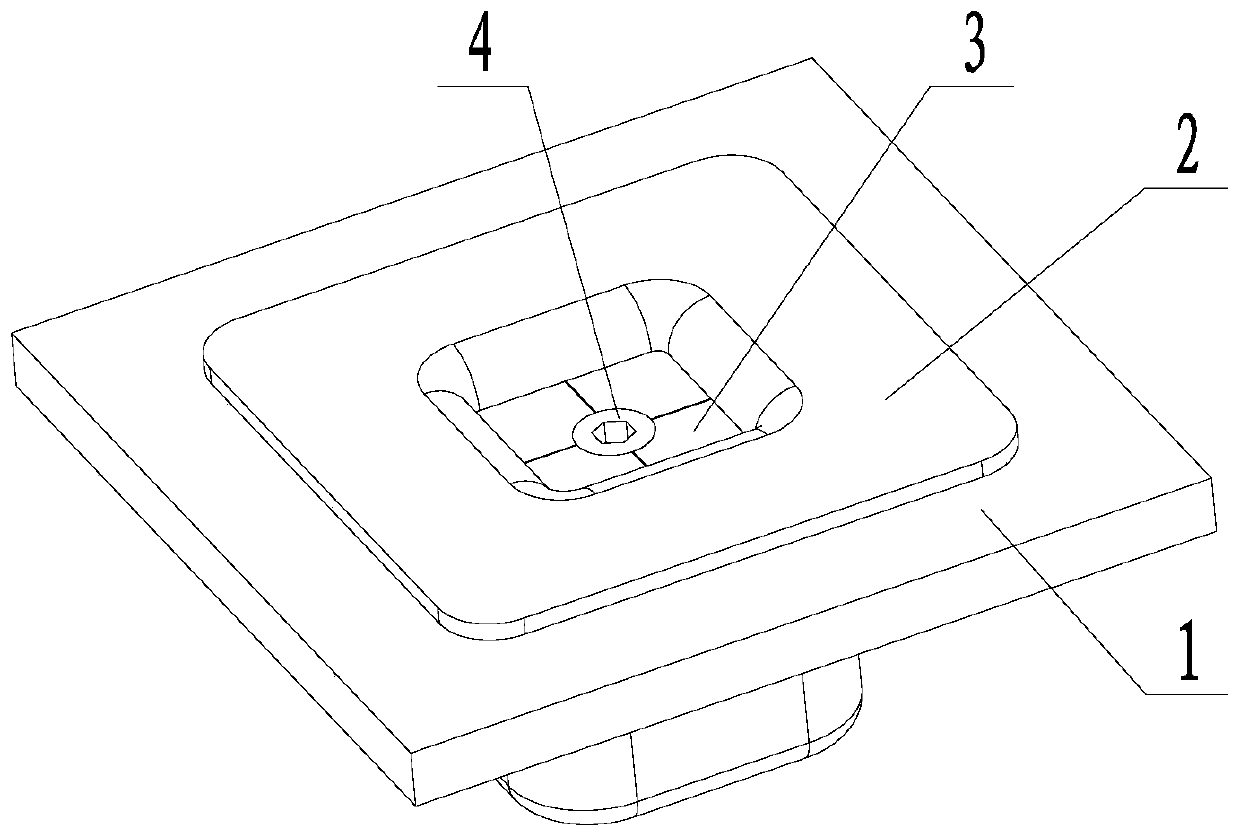

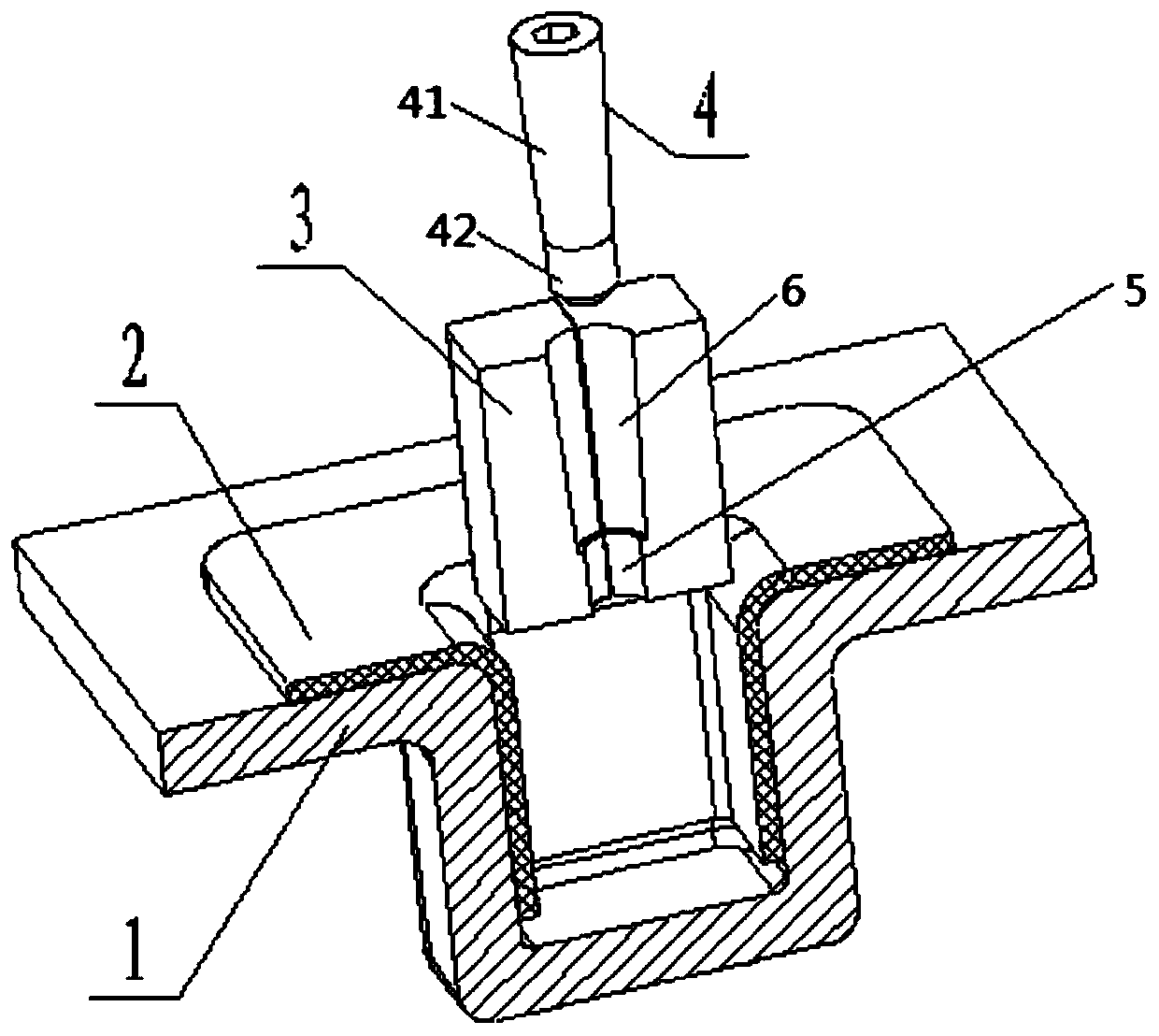

[0023] The present invention will be further introduced below in conjunction with the accompanying drawings. A composite material small pit forming pressurization device according to the present invention includes a forming die 1 and a composite material structural part 2. The forming die 1 is provided with small dimples. Pit, a small boss at the bottom of the composite material structure 2, the small boss is set in the small pit, and four closely arranged pressure blocks 3 are arranged inside the small pit, An arc-shaped groove is arranged on the top corner of each pressurizing block 3, and the arc-shaped grooves are successively connected to form a tapered hole, and a tapered mandrel 4 is arranged inside the tapered hole.

[0024] The upper part of the tapered mandrel 4 is a tapered post 41 , and the lower part is a threaded post 42 . The upper part of the tapered hole is a bell mouth 6, and the lower part is a cylindrical hole 5, and the conicity of the bell mouth 6 is cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com