Drill head for deep hole cutting

a drilling head and drilling head technology, applied in the direction of tool workpiece connection, manufacturing tools, transportation and packaging, etc., can solve the problems of deterioration of processing accuracy, deterioration of roundness, cylindricality, straightness, etc., of cutting holes, and achieve the effect of improving the pressure balance during drilling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

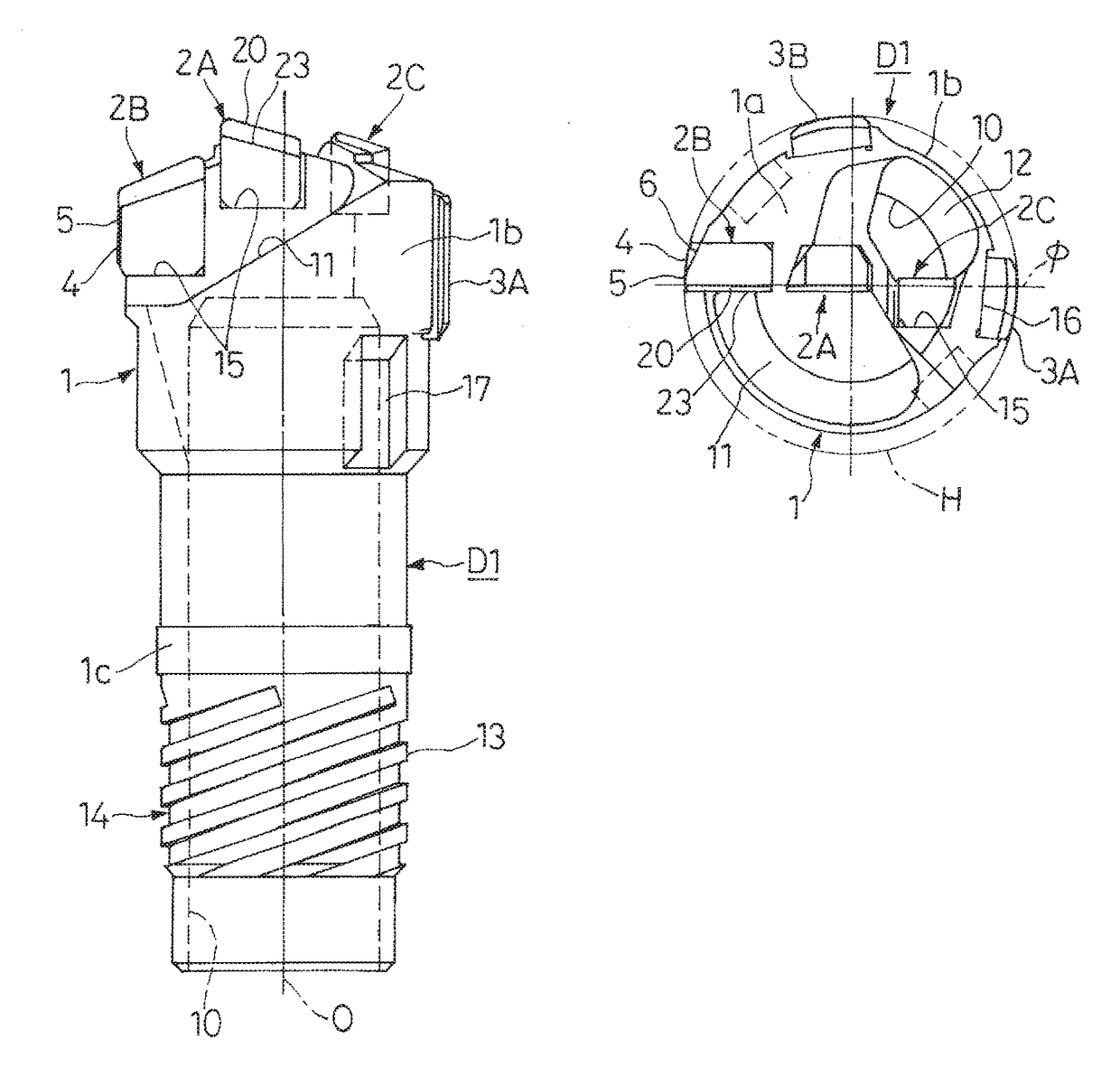

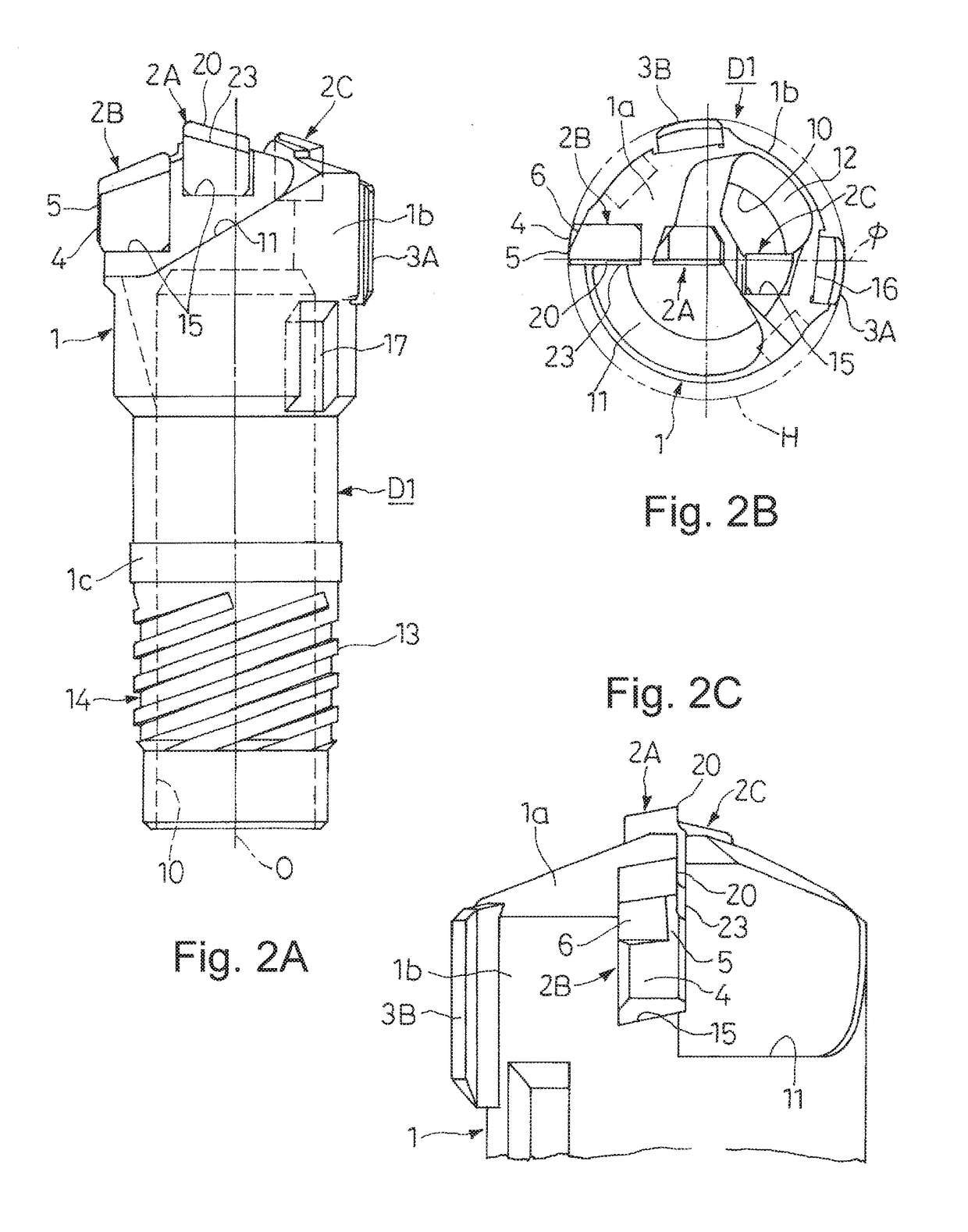

[0036]In deep-hole drilling work using the drill head D1, D2 for deep-hole drilling of the first or second embodiment, while rotating the drill head D1, D2 coupled to the above-mentioned boring bar (whose illustration is omitted) or a work material, a coolant supplied through a gap between the inner circumference of a cutting hole H and the outer circumferences of the hollow boring bar and the drill head D1, D2 is continuously fed to a cutting region, and cutting chips generated at the cutting region are caught in the coolant and discharged to the outside from the cutting chip discharge ports 11 and 12 of the drill head D1, D2 through the hollow inside portion of the boring bar.

[0037]In this drilling work, the guide pad portion 4 provided on the outer end surface of the circumferential portion cutting blade tip 2B slide-contacts with the inner circumference of a cutting hole H together with the guide pads 3A and 3B mounted on the outer circumferential surface 1b at the head distal e...

first embodiment

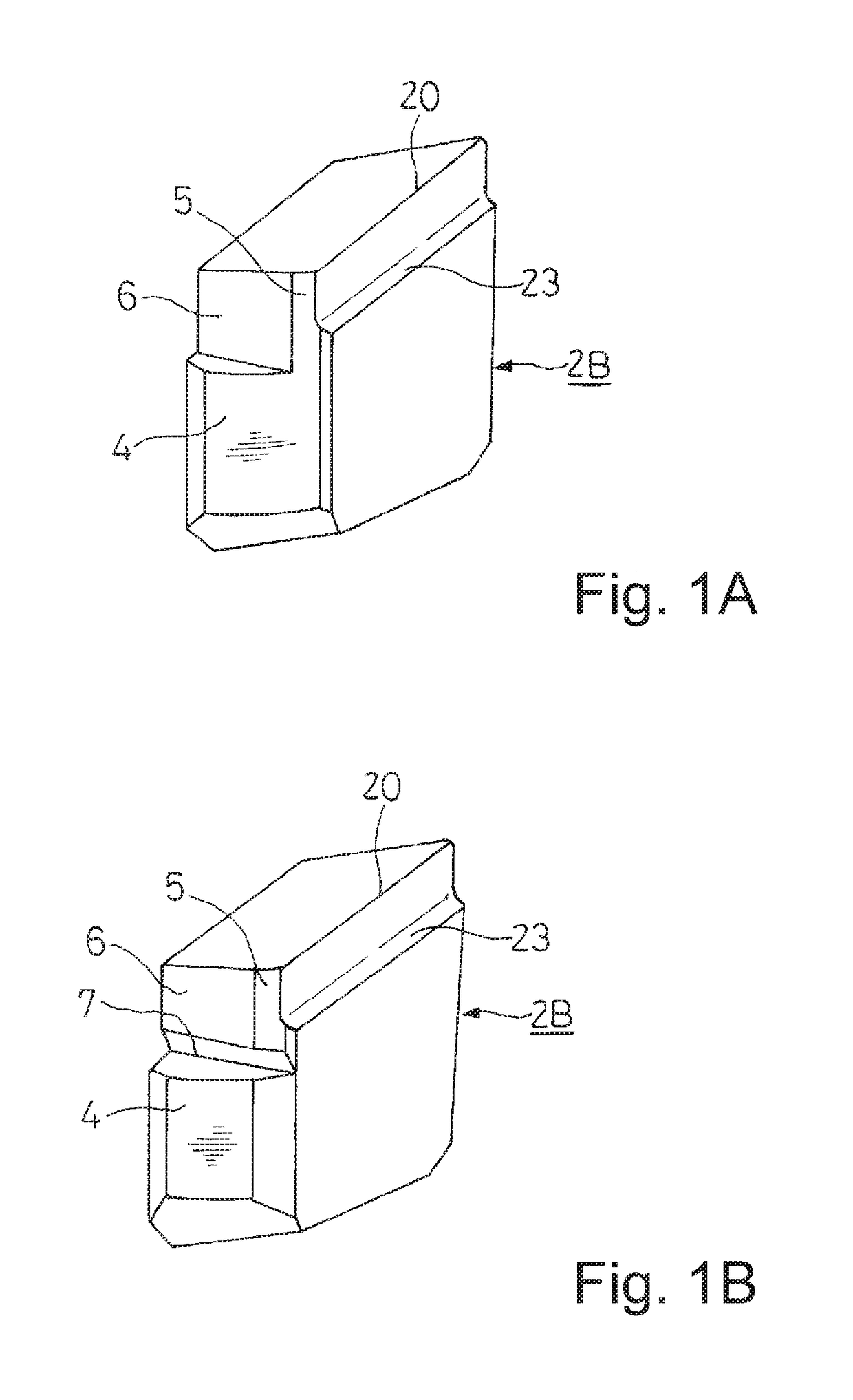

[0042]The cutting blade tip 2D in this drill head D3 has an inner end at a position slightly beyond the head shaft center O, a cutting blade 20 that is inclined upward in a two-step manner from the head circumferential side toward the head shaft center O side and further inclined downward toward the inner end side from the top portion, and a chip breaker 23 positioned on the front surface side and along the upward incline of the cutting blade 20. On the outer end surface of the cutting blade tip 2D, in the same manner as the cutting blade tip 2B of the first embodiment, a margin portion 5 facing the front edge in the cutting rotation direction and a flank face 6 to be spaced apart from the inner circumference of a cutting hole H (indicated by the imaginary line in FIG. 4B) and along the rear side in the cutting rotation direction are formed at an upper portion side, and at a lower portion side of the same outer end surface, a guide pad portion 4 is formed, and the margin portion 5 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inclination angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| circumference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com