High-temperature-resistant and impact-resistant slag well

An impact-resistant and high-temperature-resistant technology, applied in the field of high-temperature and impact-resistant slag wells, can solve the problems of high construction process requirements, high-temperature material leakage, connection failure, etc., and achieves easy large-scale manufacturing and installation, reliable thermal expansion, and good thermal insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

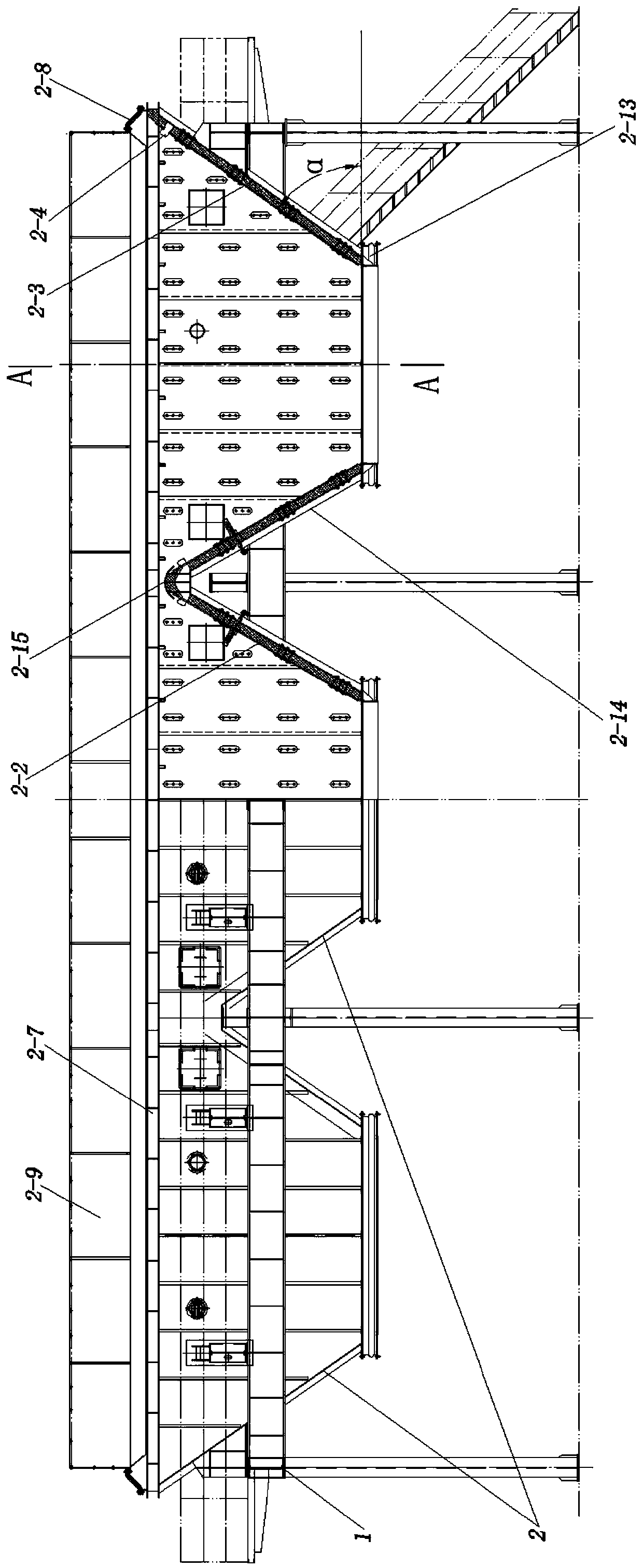

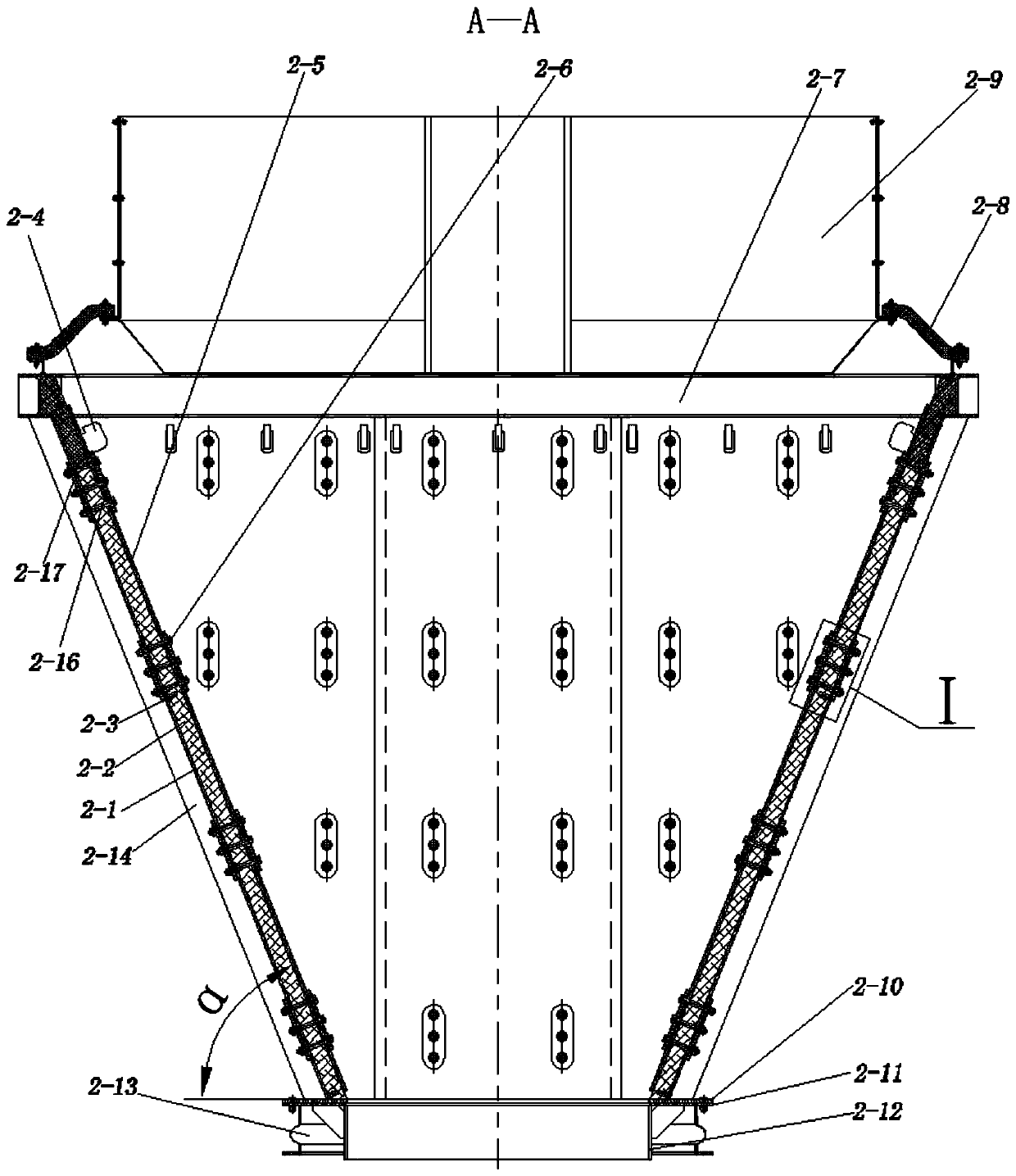

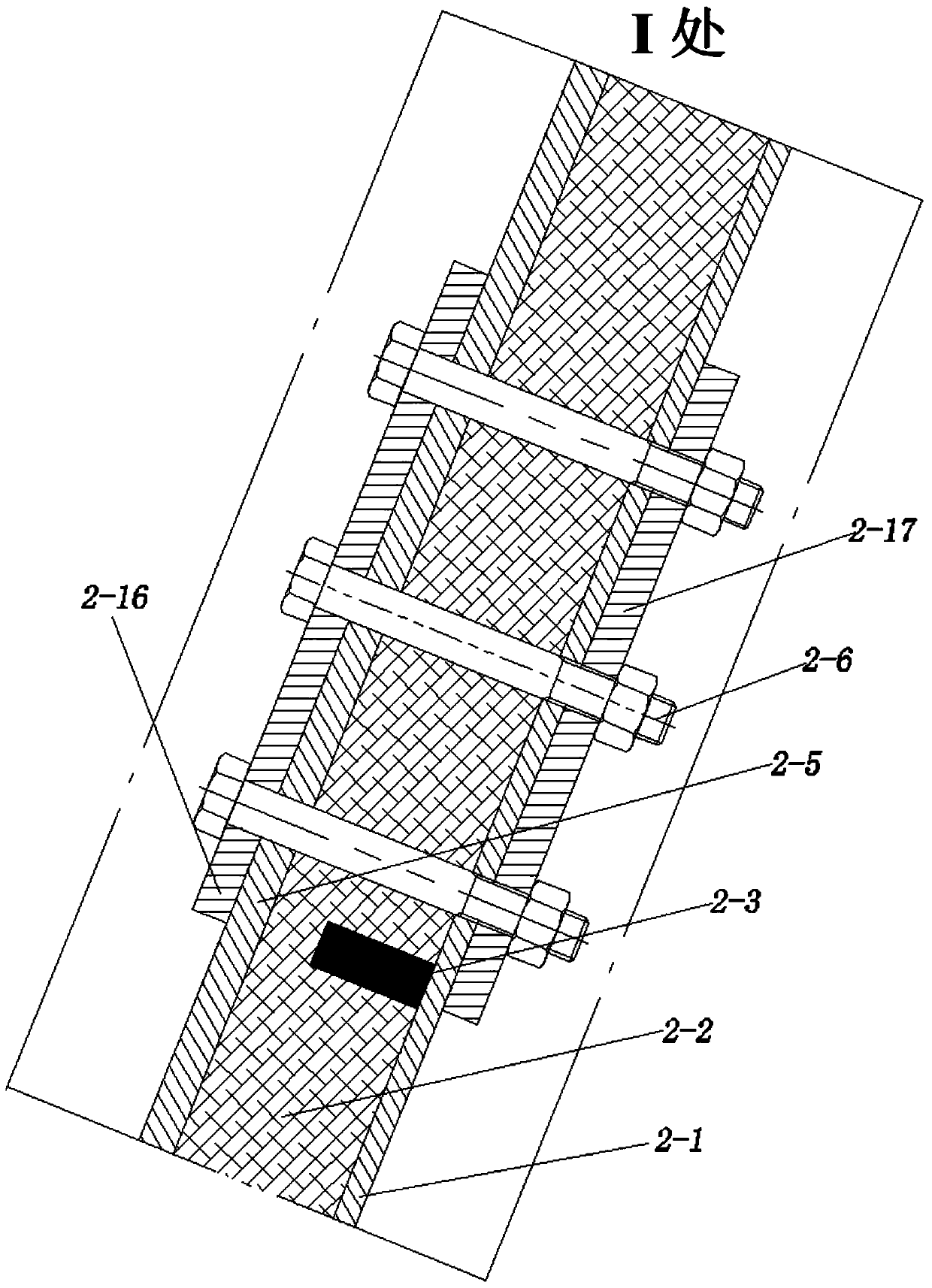

[0034] exist Figure 1 to Figure 6 Among them, the high-temperature resistant and impact-resistant slag well of the present invention includes an impact-resistant reinforced bracket 1, several conical hoppers 2 that are installed on the reinforced bracket and connected by arc-shaped middle beams 2-15 at the feed inlet; The conical hopper 2 described above includes a conical shell 2-1, a thermal insulation 2-2 installed on the inner wall of the conical shell, an anti-shock frame 2-2 located inside the thermal insulation and fixed on the inner wall of the conical shell 3. The hooks 2-4 installed on the inner wall of the upper part of the conical shell are laid on the surface of the heat preservation part and hung on the groove of the hook through the installation holes. Several inner anti-shock plates with different shapes and overlapping each other form the inner cone 2-5, Fasteners 2-6 for fastening the inner backing plate 2-16, the inner impact plate, the heat preservation pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com