Recovery and treatment equipment for sewage

A technology of sewage recovery and treatment equipment, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Simple, easy to operate, and the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

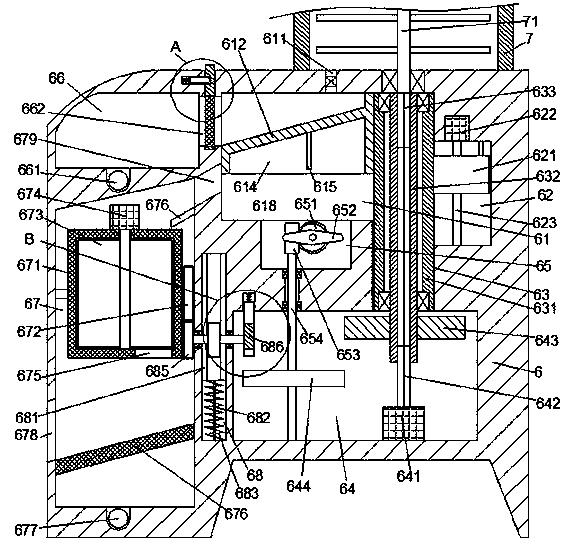

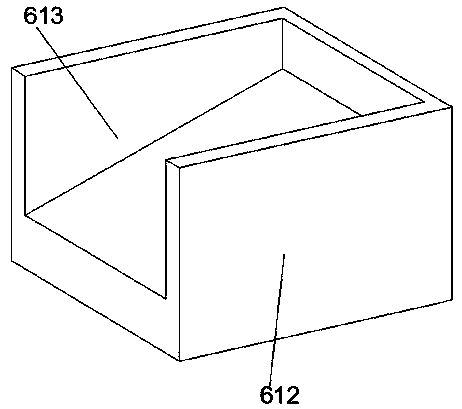

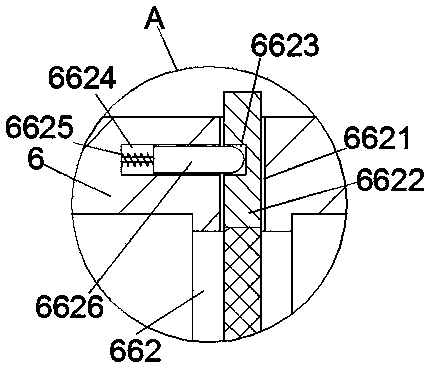

[0038] When sewage recycling is required, the first motor 641 drives the second outer key shaft 642 to rotate, and then the second outer key shaft 642 drives the inner key rotating sleeve 632, and the inner key rotating sleeve 632 drives the first outer key shaft 633 to rotate , and the first external key shaft 633 drives the mixer 71 to rotate, and then realizes the rapid mixing reaction of the sewage and the medicament in the mixing reaction tank 7, and then through the opening of the feed valve 611, and then realizes making the mixing reaction tank 7 The mixed sewage enters the slope groove 613 through the feed valve 611, and flows into the water inlet 662 through the slope groove 613. After being filtered by the sewage filter plate 6622, the filtered sewage enters the sewage collection chamber 66 and is discharged through the upper sewage. The pipe 661 is discharged, and the reacted sewage impurities are retained in the slope groove 613, and then the second motor 622 is use...

Embodiment 2

[0040] The second motor 622 controls the reverse rotation of the adjusting screw 623, so that the first pull cord 682 is in a relaxed state, and then the tooth condition 681 faces the top direction of the inner sliding chamber 68 because the tooth condition 681 is pressed by the second spring 683 Sliding, at this time, the tooth condition 681 drives the fifth gear 684 to rotate in reverse until the adjusting slider 621 returns to the initial position, and then the adjusting slider 621 drives the lifting sliding block 631 to return to the initial position, and at the same time, the lifting and sliding The block 631 drives the movable slider 612 to return to the initial position, and at the same time, the centrifugal filter bucket 671 is rotated to the initial position, so that the dehydrated sewage sediment impurities in the centrifugal filter bucket 671 fall on the inclined filter guide plate 676 and then pass through the discharge port 678 Drain, the water liquid produced duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com